Home › Forum › Ask A Member › Johnson KD-15 Points Adjustment and Carb Pepair

- This topic has 3 replies, 2 voices, and was last updated 2 years, 2 months ago by

Buccaneer.

Buccaneer.

-

AuthorPosts

-

January 31, 2023 at 1:11 am #272124

AOMCI Members…..

Ive picked up a 1948 Johnson KD15 (manufactured in Peterboro, Ontatio I think – with Metallic green paint) that looks to have lower hours at an estate sale.

Broke the motor down to asses the overall condition and noted one of the exhaust ports completely plugged. Cleaned the entire exhaust system including some minor crud in the mid section where the top half meets the mid-section. Pistons and cylinder walls looked great and overall condition of the motor is excellent.

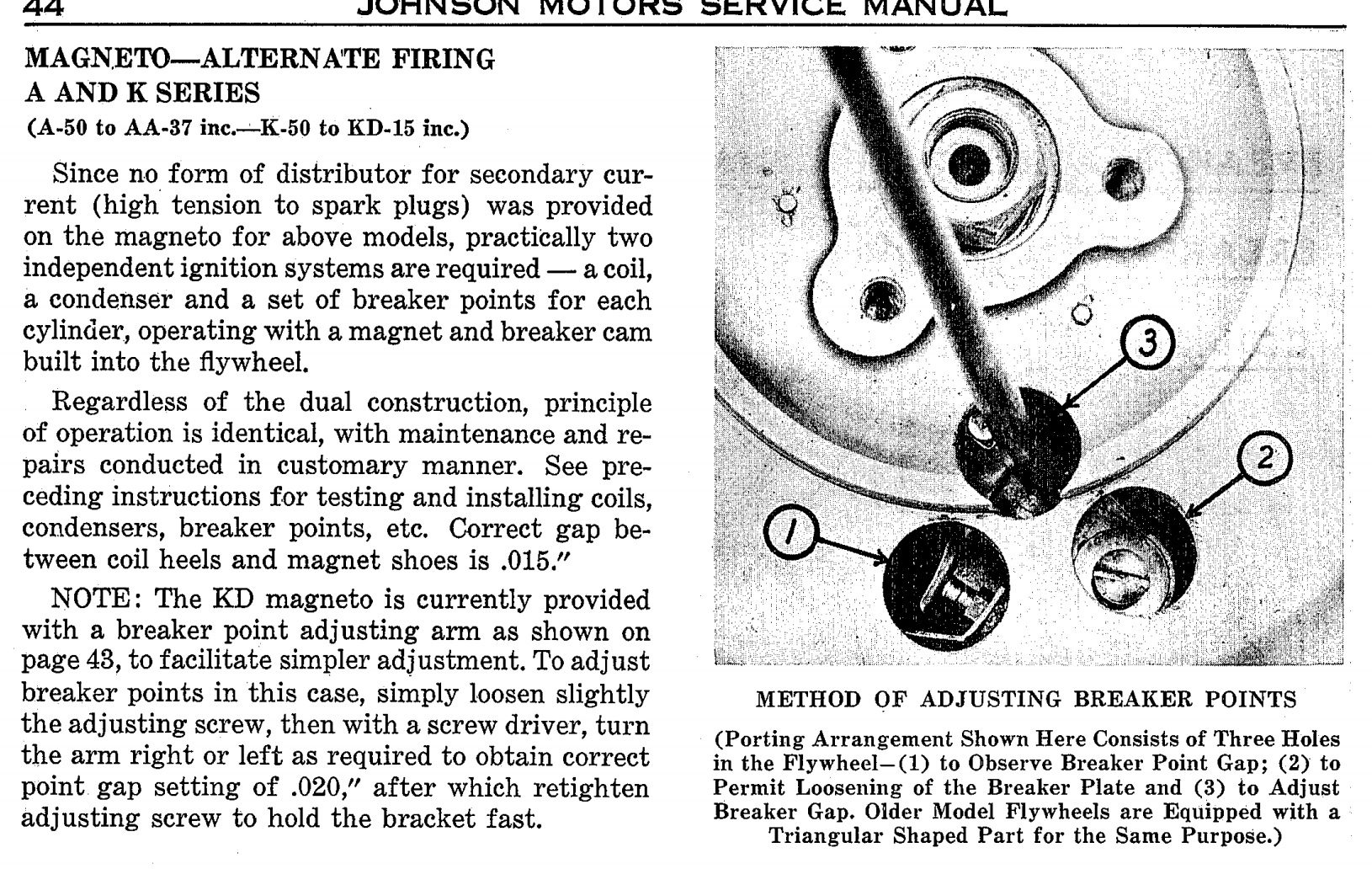

Noted one coil is bad, points had mild corrosion and were cleaned, plug wires will need replacing, and so will the plugs. One question on adjusting the points. There are three 1/2 in holes on top of the flywheel for adjustments. However, when checking spark after cleaning and trying to set the points, I’ve noticed two of the holes line up perfect to set the gap, but its incorrect. The points open too early thus the gap is too far open giving no spark. If I rotate the flywheel almost a half inch then try to set the gap visually at .020 via the third opening, I get a spark but its not set correct with out a gauge between the points (its too difficult to get my gauge in the hole to correctly set the points). What is the correct procedure for setting these points? Ive searched the forum and cant find anything. Nor can I find a manual.

In the carb, when dis-assembling, the rotating metering valve stem (called a barrel valve in the parts manual) was busted and came apart in my hand (its spring loaded). Is their a fix for this or is this part available through a member? Do I need to get a new carb assembly? If so, any suggestions where?

Any feedback and advice to a fellow AOMCI member is appreciated!

Rick

-

This topic was modified 2 years, 2 months ago by

Mumbles.

Mumbles.

January 31, 2023 at 9:01 am #272134January 31, 2023 at 10:45 pm #272172Thank you for the excerpt from the manual. I thought thats how the points were to be adjusted – it made sense. However, I still have no spark when utilizing the three openings in the flywheel when following that procedure. I need to move the flywheel a half inch further and set the gap visually, then I get a spark. Odd to say the least. Below is a picture of my flywheel. Maybe the cam lobe is incorrect, and is from another model? Is the flywheel from another model engine?

Any feedback appreciated.

Thank You.

February 1, 2023 at 9:37 am #272179It wasn’t that long ago that I worked on the same motor.

If you search the forums, there should be a thread in

Current Projects.After thinking about it, I think I too had problems adjusting the points

using the instructions, and ended up checking the points “gap” in hole

#2, which was awkward, as I had to keep going back and forth between

holes to adjust, then check the gap. Perhaps that would work for you.I test ran my motor (video on thread) for a few seconds, and it sounds

like it may be a good runner.As far as the carb throttle spool, that would be a difficult “fix”.

Best to put an ad in the classifieds, and scour EBay.Edit: I guess my project was a KA-10, but very similar motor I think.

https://www.aomci.org/forums/topic/1940-johnson-ka-10-9-8-hp-2/Prepare to be boarded!

-

This reply was modified 2 years, 2 months ago by

Buccaneer.

Buccaneer.

-

This topic was modified 2 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.