Home › Forum › Ask A Member › Johnson MD-38 Magneto

- This topic has 18 replies, 7 voices, and was last updated 4 years, 11 months ago by

lloyd.

-

AuthorPosts

-

February 29, 2020 at 1:39 pm #196202February 29, 2020 at 6:28 pm #196271February 29, 2020 at 6:42 pm #196277

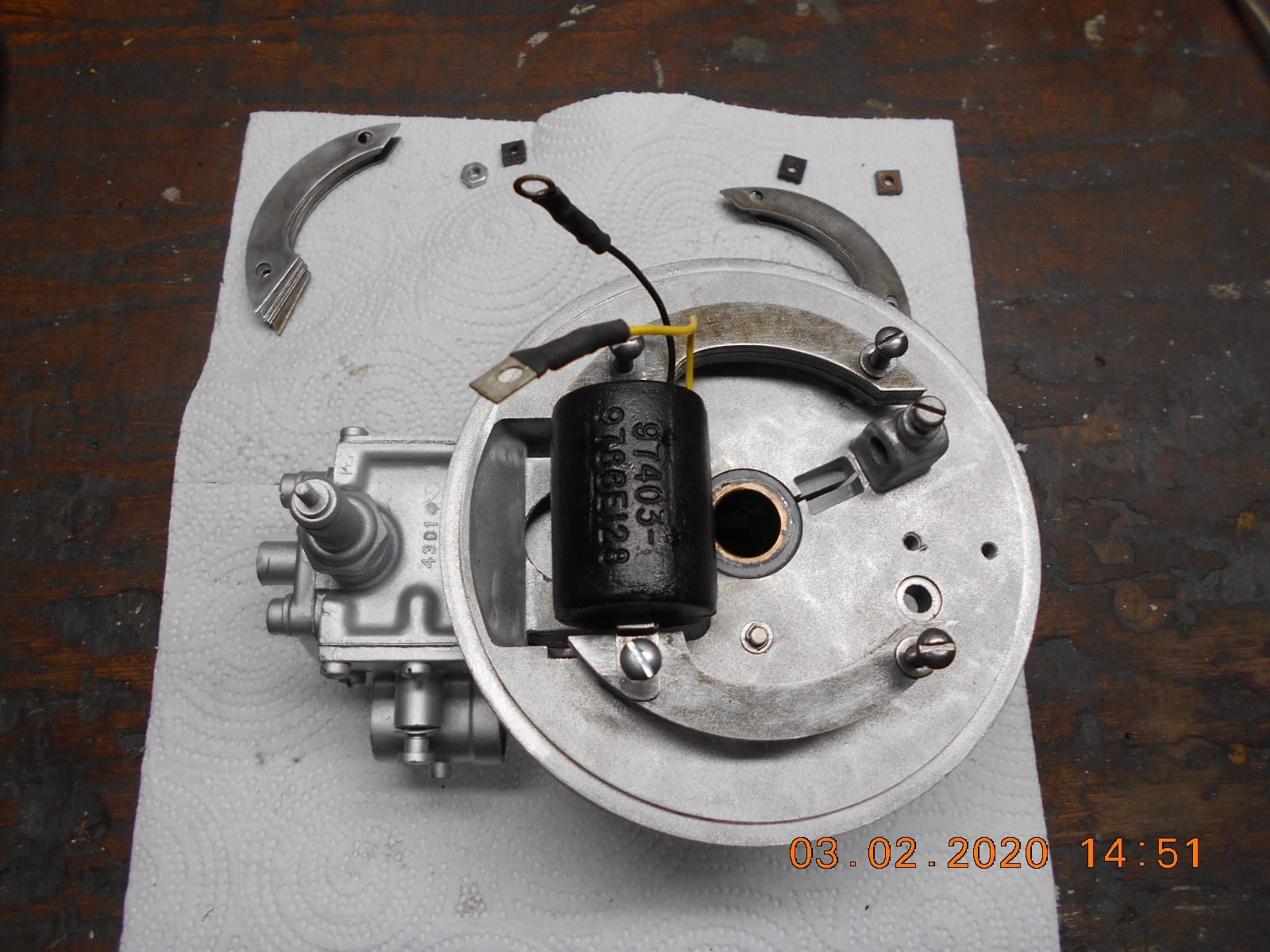

Had this “Military” specs Scintilla type coil in the cabinet for a rainy day…… or

a 37 degree sunny day, in this case. It’s the same diameter as the original

Johnson coil, and close to the same length.

Removing the laminate core from the Military specs coil fought me the whole way.

I had to cut off some of the laminate pieces on one end, then start driving them

out with a punch. The punch kept binding up. I ended up switching to using

the tang of a small flat file, which I had to grind down some to make the tang longer.

I finally got the core out, and the coil still test okay on the ohm meter!

I was hoping to be able to use the laminates out of this coil, and just add the

center piece from the original coil, that has the mounting holes for the mag plate,

but that option went out the door when I got out the hack saw. I’ll have to grind

down the original coil laminates to fit, but I had enough fun for today!

Prepare to be boarded!

March 1, 2020 at 12:02 pm #196338The PM picture I sent

is about this substitution.A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

This reply was modified 4 years, 11 months ago by

Tubs.

Tubs.

March 1, 2020 at 5:15 pm #196371The PM picture I sent

is about this substitution.-

This reply was modified 4 years, 11 months ago by

Tubs.

Tubs.

Tubs, if you’re talking about the photo cropped together of the mag plate and

Lockwood lower unit, I’m still not sure what coil you used.Looks like you had to grind a little off of the coil case…..

how do you know how much you can grind off before it’s too late?Prepare to be boarded!

March 2, 2020 at 10:59 am #196420

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

March 2, 2020 at 12:34 pm #196444Tubs, I understand now! The military style coil I’m using on the MD38 didn’t have

laminates long enough to span the mag plate mounting bolt holes. I would have liked

to re-used the laminates (except I’d still would have needed the longer one from

the original coil that’s has the mounting holes) so I wouldn’t had to grind the original

laminates down to 3/8″ to fit the military style coil. Unfortunately, I couldn’t get

the laminates out of the military style coil without destroying most of them!

The laminates in the original coil came out in about 30 seconds!I finished refitting the laminates in the military style coil this morning, and am

cleaning up the rest of the mag plate now. Hopefully I’ll be checking for

spark on the new coil in a few days. Got new rings today, so I can put the

power head back together any time. Have to take a couple hours off and get

more firewood to heat the shop…… Hopefully not next year, lol.Prepare to be boarded!

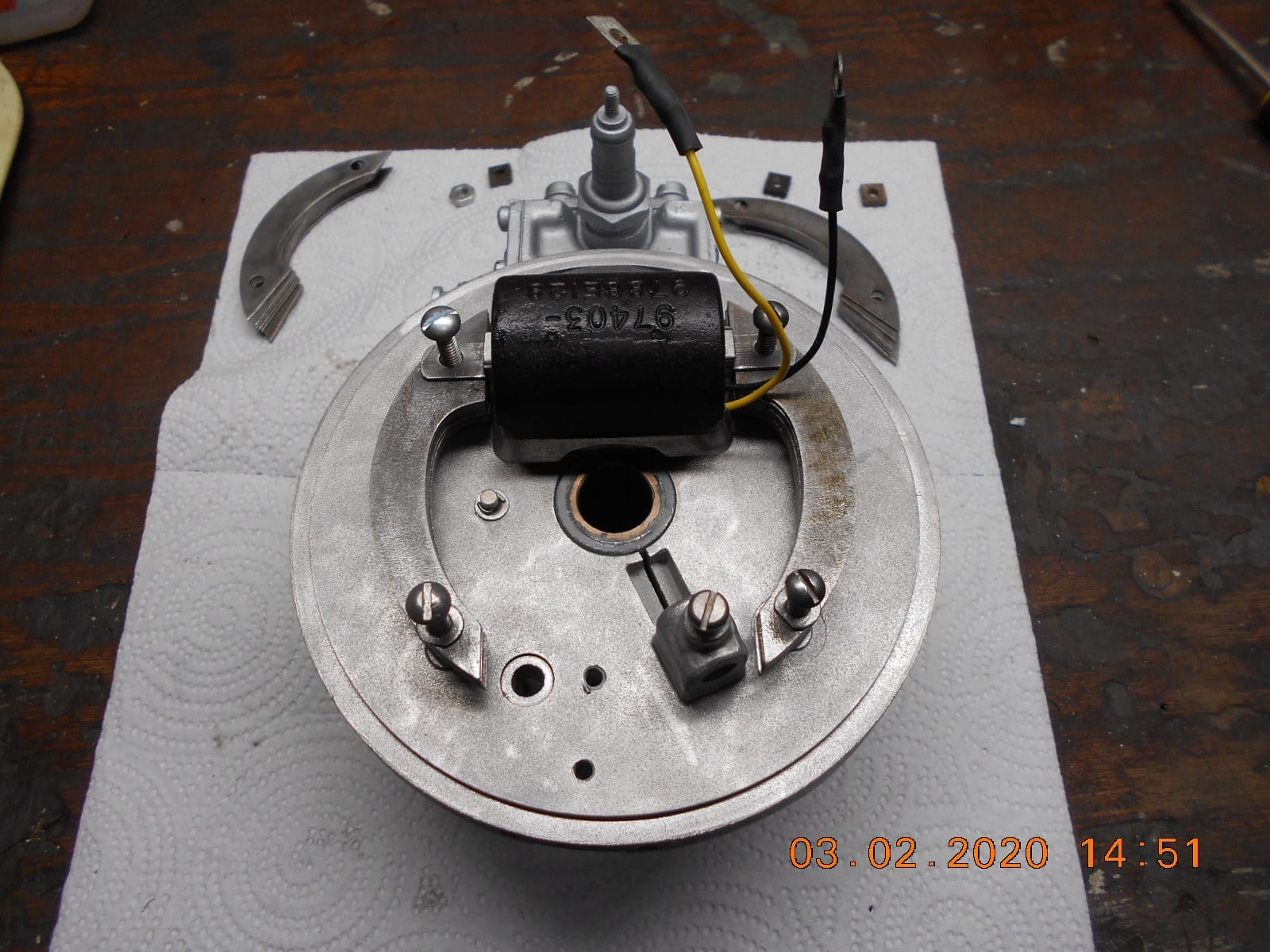

March 2, 2020 at 6:40 pm #196472I got the military specs coil mounted today, and after these photos were

taken, soldered on the spark plug wire. Also test fitted the flywheel for

clearance around the coil. I “think” it will be okay, but hard to tell until

the powerhead is fully back together.Now, I’m wondering what mfd cap or condenser I should use

for this coil? Can I assume / hope that the rating would be the

same as a singe cylinder Mercury using the Scintilla coil?Thanks.

Prepare to be boarded!

March 3, 2020 at 1:24 pm #196534Wow, Tom! You make this stuff look easy. Nice job.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

March 3, 2020 at 5:21 pm #196550Some of the conversion was easy, and some I worked way harder than

should have been necessary!

Got the rest of the mag together today. I ended up cramming two .1 mfd

caps in an old condenser can, mounted where the original condenser was.

That reminds me, I need to order some .20, or .22 axial caps again.

I got rid of all the soldered wiring joints, (as they were like the MS-38

shown) coil to points, condenser & kill post, which will make taking it apart

easier, if needed in the future, like if my conversion doesn’t work!

Also put the powerhead back together today, which brings up another issue,

but I’ll start a new post for that.Prepare to be boarded!

-

This reply was modified 4 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.