Home › Forum › Ask A Member › Johnson piston ring chart question

- This topic has 3 replies, 4 voices, and was last updated 9 years, 8 months ago by

r-c.

-

AuthorPosts

-

January 30, 2016 at 10:01 pm #3522January 31, 2016 at 12:19 am #31091

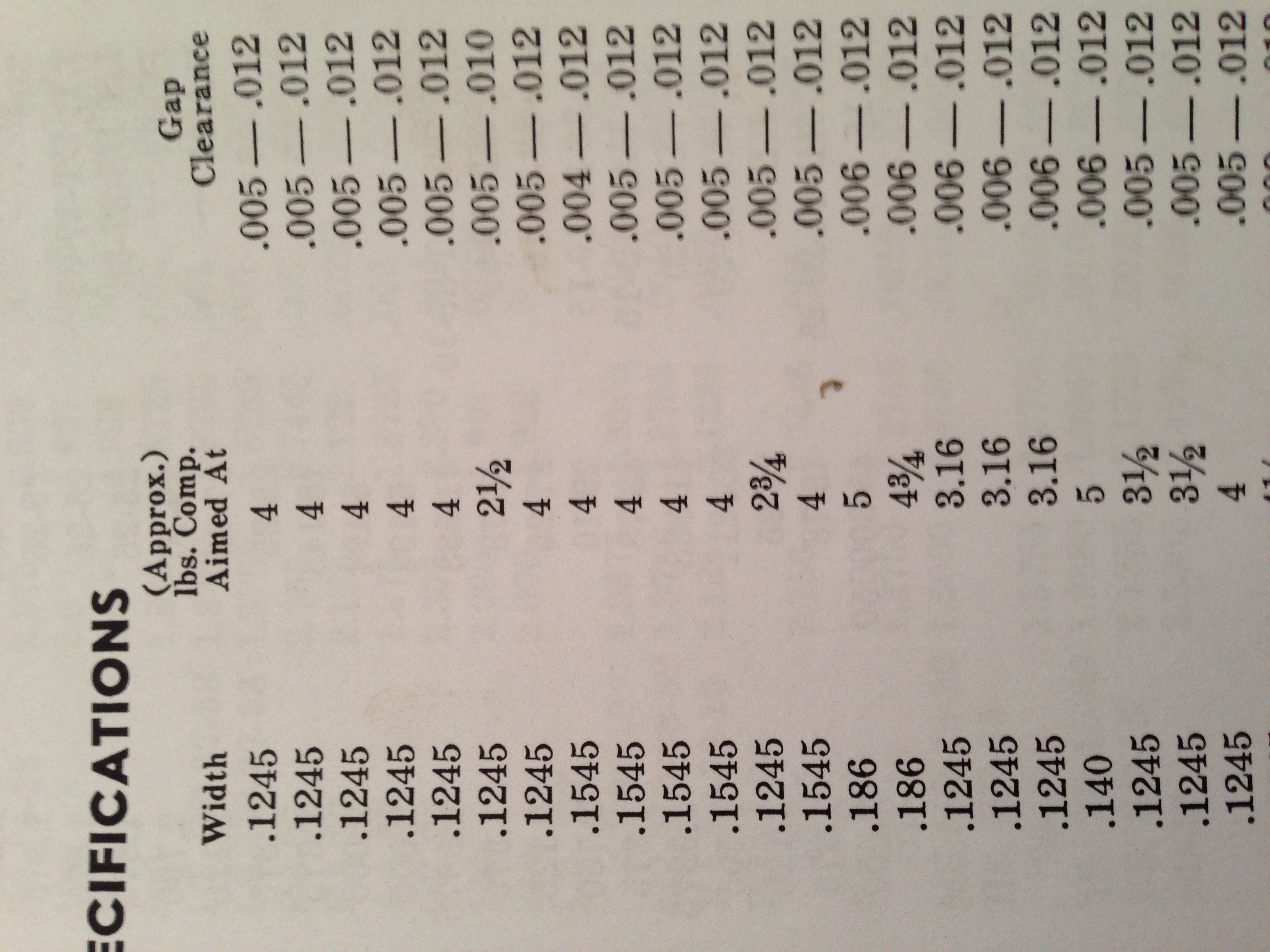

Evinrude manual says "Lb. Compression Recommended when Compressed". I don’t know, I always thought it referred to the squeeze force needed to compress them to cylinder bore dimension. I don’t know how that would be measured though.

January 31, 2016 at 12:49 am #31092I would assume so also Frank. Could you tell me what Johnson manual you got that from? I haven’t noticed it before. I know when engine overheat badly they lose their ring tension. Never thought of a way to measure it, just usually have to change things (pistons, bore out of round, etc.) because of other problems on bigger engines. In the old days labor charges were not a problem ( like we are today with our own old motors ). They just took them apart, checked everything, decarboned and put them back together provided everything was in spec. I like the one that shows knocking the piston back round again after the wrist pin has been installed if necessary.

Dan in TN

January 31, 2016 at 4:48 am #31097It would appear you would need a scale that could compress the ring. Where to find one? Don’t know. It would also appear you need a jig of some sort to keep the ring from twisting while under compression. None of this is addressed in the service manuals and doesn’t appear after the early 1050’s books.

This is something we never have done, at least in my experience. We put the ring in the cylinder to check butt gap and as long as the ring doesn’t fall out of the cylinder it is good.

The static spring tension against the cylinder wall has little to do with operation. A too strong ring pressure against the cylinder wall will help static pressure tests with your compression gage. So what? And if you had one of our racing motors with mulit-ports and the spring tension is too much, it catches a port and breaks!

A good seal always helps starting. However too much pressure will wear out the ring and cylinder earlier in life.

The whole ideal is to have clearance between the ring and land, about 0.003" and space behind the ring (which the manufacturers have figured out) for the gas pressure to do the sealing on the compression stroke.

Some worry about things that don’t matter. I have stated that life at 5,000 rpm is much different than 10,000 rpm! -

AuthorPosts

- You must be logged in to reply to this topic.