Home › Forum › Ask A Member › Johnson PO-15s – Where do I start?

- This topic has 13 replies, 6 voices, and was last updated 3 weeks, 4 days ago by

joecb.

-

AuthorPosts

-

March 21, 2025 at 11:14 am #294800

Looking for a little guidance

I was given 3 PO-15s. ’46,’48 and 50.

One has the kill switch and wiring. One has a wire that’s cut a couple inches from the points and one has no kill switch wire

I don’t see any spark from any of them. Seems to me that at least one of these should have spark which makes me think I’m missing something about these motors. I’ve looked at a bunch of posts on this forum and found some good info but……..

Is there something I can check after pulling the flywheel off before removing or disconnecting anything?

Does the compression lever have to be in a certain position to get spark or is it just releasing compression to make it turn over easier?

It looks like the kill switch is a Momentary close switch (I only have one tiller with the switch) that grounds the points when pushed. with no wire or a cut wire I’m assuming this should NOT prevent spark

I’ve worked a lot on the smaller Johnson motors and replaced coils and points etc on those but this is a bit of a different beast

Any direction would be appreciated. Thanks

March 21, 2025 at 11:28 am #294806The PO15 is not that different from the earlier A-45,just a lot bigger.The compression release has no bearing on spark,it just makes for easier pulling to start.If you remove the rope plate held on by three screws on top of flywheel,you will be able to access and clean the points.Although the coils are usually good,you can use a multi meter to check resistance between plug wire ends.Next most likely culprit would be condenser and you’ll have to remove flywheel to access that.

1 user thanked author for this post.

March 21, 2025 at 12:16 pm #294807The PO15 is not that different from the earlier A-45,just a lot bigger.The compression release has no bearing on spark,it just makes for easier pulling to start.If you remove the rope plate held on by three screws on top of flywheel,you will be able to access and clean the points.Although the coils are usually good,you can use a multi meter to check resistance between plug wire ends.Next most likely culprit would be condenser and you’ll have to remove flywheel to access that.

What should spark plug wire to wire read for resistance?

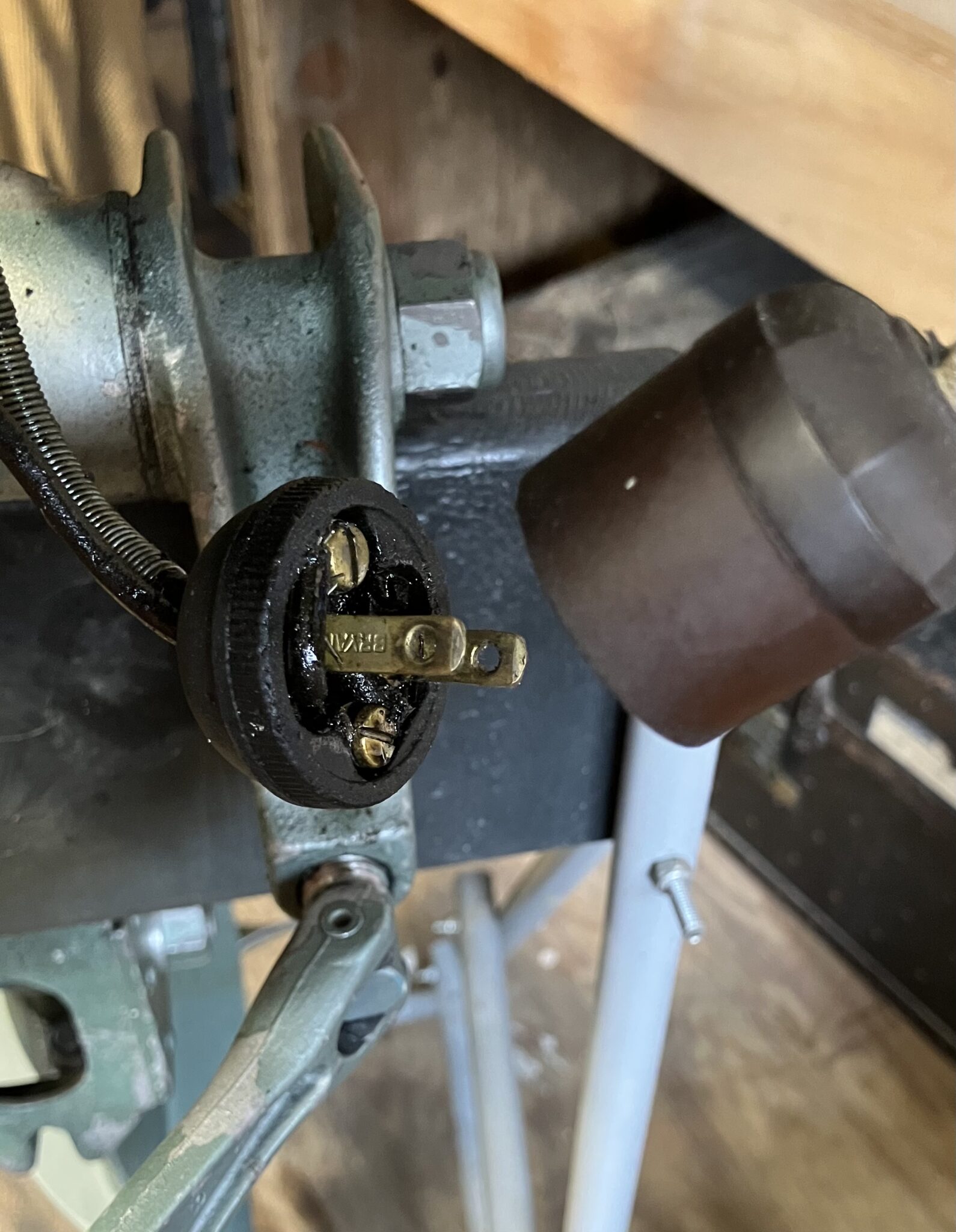

March 21, 2025 at 1:10 pm #294808March 21, 2025 at 1:15 pm #294810Disconnect for the cutoff switch is just a lamp cord plug.

the male end goes to the mag and female end to the tiller.

My PO is a 1948, coil, condenser, and points are original. It is my favorite motor to run.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

March 21, 2025 at 1:33 pm #294812To see spark at either plug, you need to ground the other wire.

T

March 21, 2025 at 2:00 pm #294814To see spark at either plug, you need to ground the other wire.

T

What ‘other’ wire are you referring to? I had a spark tester on the plug to start and then I removed that and only touched the plug to the head cover still nothing. Not sure what other wire you are talking about? Thanks

March 21, 2025 at 2:21 pm #294816What Tom said… two SP wires…. one must be grounded in order to test for spark on the other wire.

Joe B

1 user thanked author for this post.

March 21, 2025 at 7:37 pm #294817On all 3 motors I’m measuring open circuit across the two connection points to the coil of the plug wires. Circled points in the picture. So I either have 3 bad coils or still not measuring correctly

March 21, 2025 at 10:48 pm #294824Yor are measuring correctly. I good coil should be about 7000 to 8000 Ohms. An “open” would indicate a bad coil. However, I have seen coils that check open but still produce a spark. Now I wouldn’t trust such a coil for a transatlantic cruise but might be OK for put-put around the pond.

Joe B

-

AuthorPosts

- You must be logged in to reply to this topic.