Home › Forum › Ask A Member › Johnson S45 – Stuck – Which Piston to tap?

- This topic has 20 replies, 12 voices, and was last updated 4 years, 8 months ago by

2fast4me.

-

AuthorPosts

-

January 12, 2020 at 5:46 pm #191889

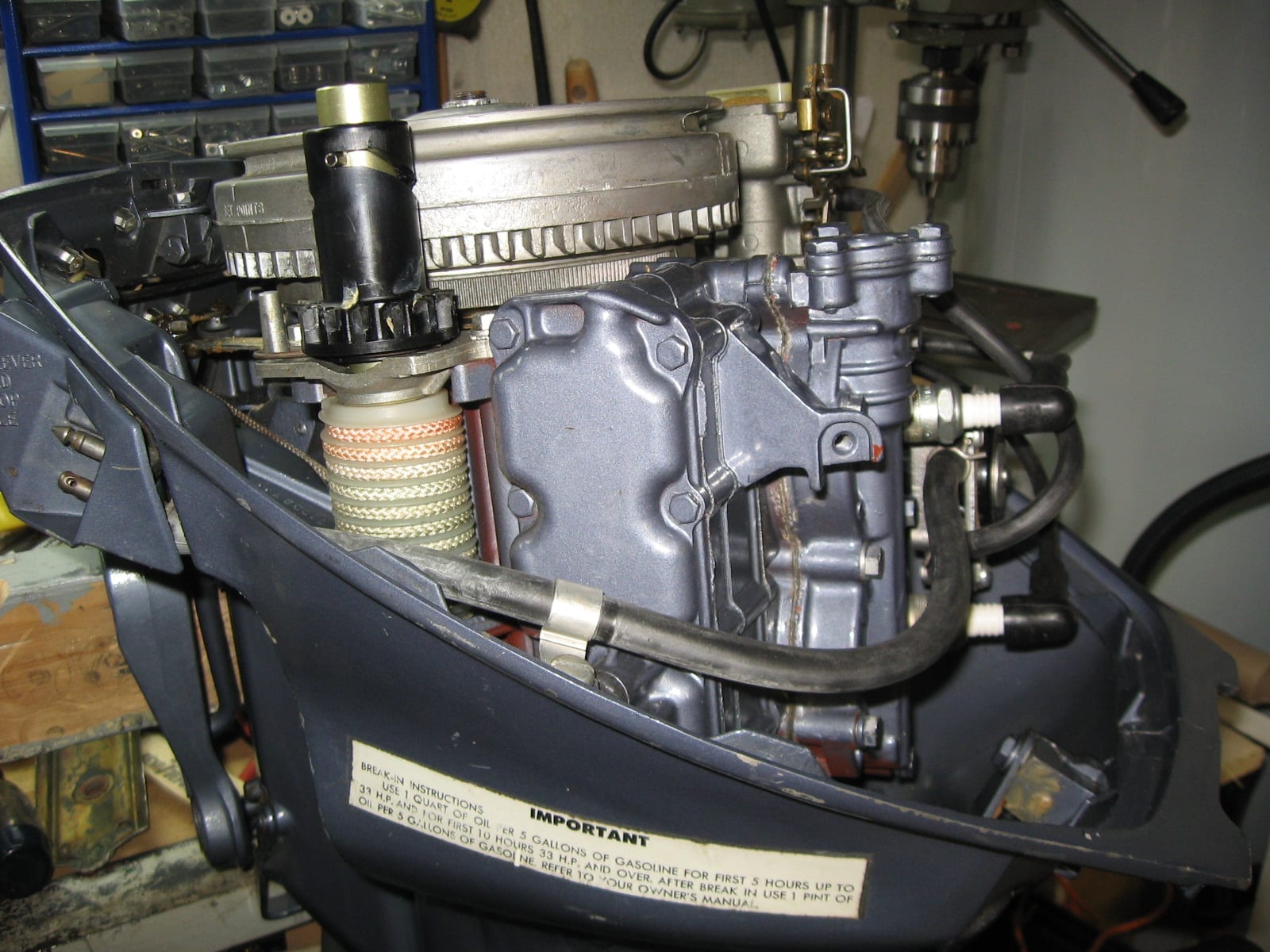

My daughter found an S-45 located in a friend’s field. She managed to snag it as a Father’s Day present for me, which was probably the best present I ever received. Beats a tie anyway. I’ve been polishing the S-45 (serial 123311 I think) and trying to straighten the tank enough to apply a new decal then hang it as a display at the cottage. The aluminum and the brass prop are pretty spectacular looking now. The S-45 is also about the same age as the 1933 cottage.

The S-45 is stuck. I was hoping to get it to turn over before mounting it on the wall. I’ve been “soaking” it in Sea Foam Deep creep for a few months. I sprayed the penetrating oil into the spark plug holes and let it sit. Today I got inspired and took off the heads. It looks rusty in there but not badly pitted. I’ve been tapping away at the cylinders and using a 2′ breaker bar on the flywheel nut. No hard reefing or hammering. So far, no luck getting it freed up.

The left piston and right piston are in the same position. Looking at a couple of opposed twin parts diagrams I see only one coil. Do these opposed twins fire at the same time? So, am I safe to assume that the pistons are both on either compression or exhaust stroke? Could I get a buddy and have both of us tap on opposing cylinders in unison? How about adding some torque on the flywheel nut if it can be determined the motor is on the exhaust stroke?

Appreciate some feedback. Thanks in advance for your help.

January 12, 2020 at 8:01 pm #191923Nice find.

With stuck opposed twins, penetrating oil, heat and time are your friends.

I would strongly advise against using a breaker bar and torque on the flywheel nut. That very possibly will lead to a broken crankshaft.

What I would do is take the power head off and immerse it in PB Blaster or the penetrant of your choosing.

If you can get the cylinders off far enough you may be able to get the rod bolts off which will make piston removal easier. If the cylinders are not bad off you may even be able to take it for a ride.

Opposed twins fire at the same time.-

This reply was modified 5 years, 5 months ago by

lyks2tinkr.

January 13, 2020 at 12:18 am #191937I unstuck a few by pulling the cyl head soaking with penetrating oil and…..firm tapping the cylinders alternately with a 1″ round wood peg

hopefully you will see the oil level go down after a while indicating the rings are absorbing some oil .

I scribed the flywheel and frame to establish a referrence point it was easier to see the initial but very small movements as pistons started to free up.

there is no rushing it …. if the innards are not all rusted up….. hopefully it will free up

patience brings joy.. as in my nice $50 turtle 9.5hp which was hard stuck and is now my favorite kicker supporting my 75hp ETEC

Joining AOMCI has priviledges 🙂

January 13, 2020 at 12:27 am #191941As mentioned, don’t reef on the flywheel nut or you chance breaking the end of the crankshaft off or splitting the flywheel. Try using a strap wrench instead on the flywheel itself.

If both cylinders could be unbolted from the crankcase and the crankshaft can be turned, you might be able to undo the rod caps and then be able to remove each cylinder along with its piston. This way you could put it in a press and coax the pistons to move easier than trying to get both of them to move together while completely assembled.

January 13, 2020 at 5:47 pm #192023Thanks all for the responses. I think I will try turning the motor on its side and put some penetrating oil to one cylinder and see if it disappears as Crosbyman suggested. It that works, I will then flip the motor 180 degrees and work on the other side, then try the tap tap tap. If all fails, I will give the cylinders a try.

January 13, 2020 at 9:27 pm #192041It would be a good idea to spray the cylinders from the crankcase side as well. Good luck

January 14, 2020 at 9:51 am #192065January 14, 2020 at 10:38 am #192068Using Tubs method of removing cylinder will work as long as it’s not too tight. But you can break off cylinder mounting flange if you apply too much pressure with bolts.

January 14, 2020 at 11:41 am #192070

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

January 14, 2020 at 9:27 pm #192096OK, so everyone is assuming the pistons are stuck. That may not be the case. The S-45 has a bunch of places where corrosion could prevent the motor from turning.

First, remove the lower unit. Simple removal of 3 nuts and it should drop down. If the motor doesn’t turn and the propeller turns, that’s not it. Re-install the lower unit.

Next remove the rotary valve on the front of the engine. Make sure you index the position of the gear when you remove it so you can install it as it was. If the motor doesn’t turn and the gear does, check the index of the gear and replace it.

Since you’ve already, (at least I think you did), used penetrating oil in the cylinders, it could be the crankshaft is stuck. If the pistons are covering the exhaust ports (you can tell by removing the muffler) lay the engine on its back and fill the crankcase with 50:1 mix and let it soak. It will slowly work its way into the upper and lower mains—may take a couple of days. (Keep the engine away from everything for fire safety).

If the pistons are not covering the exhaust ports, turn the engine upside down (resting on the flywheel) and fill the crankcase with 50:1. Wait till you see it leak through the upper main. Then turn the engine upright and again fill the crankcase with 50:1 and wait till it leaks through the bottom main. This way you will know that the mains are lubricated. Then carefully use the strap wrench and see if the flywheel will move. Perseverance pays off! -

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.