Home › Forum › Ask A Member › Johnson TD-20 5hp points question

- This topic has 6 replies, 4 voices, and was last updated 3 years, 4 months ago by

ml_mcm.

-

AuthorPosts

-

August 24, 2022 at 11:44 am #264872

I’ve been jumping around from one motor to another trying to get some what look to be easy fixes completed before it gets too cold and work on the challenges this winter.

right now I have a TD-20 with no spark. Coils look to be good with 3.5k secondary resistance. I do have other coils with 7K secondary from a pile of parts and could swap them if more is better?

The coils also look to be ok with a jump in my meter when I check them. I have some coils that slowly rise in resistance and stop at a fairly big number and others that jump up then go to out of range/open on the meter. Again, is the quick jump better than the slow roll?

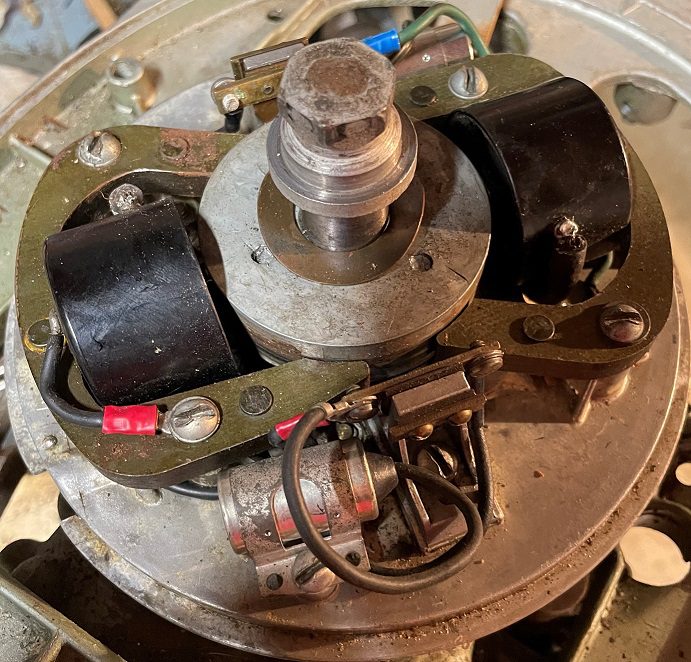

For points, it’s the push rod type with the magnet on the drive shaft. Any help in best way to make sure these are good is appreciated. I’ve done a little 400 grit (I know some don’t like this) on them and cleaned off with alcohol but any further advice on making sure these are good is appreciated.

August 24, 2022 at 12:05 pm #264875Take the point apart, clean half at a time. 320 grit is a good

starting paper, but I always follow up with finer grits, 600,

800, or sometimes ever 1000 grit.The condensers should be replaced. It’s not worth messing around

with old condensers whether they test good or not, IMHO.Your coils probably are okay.

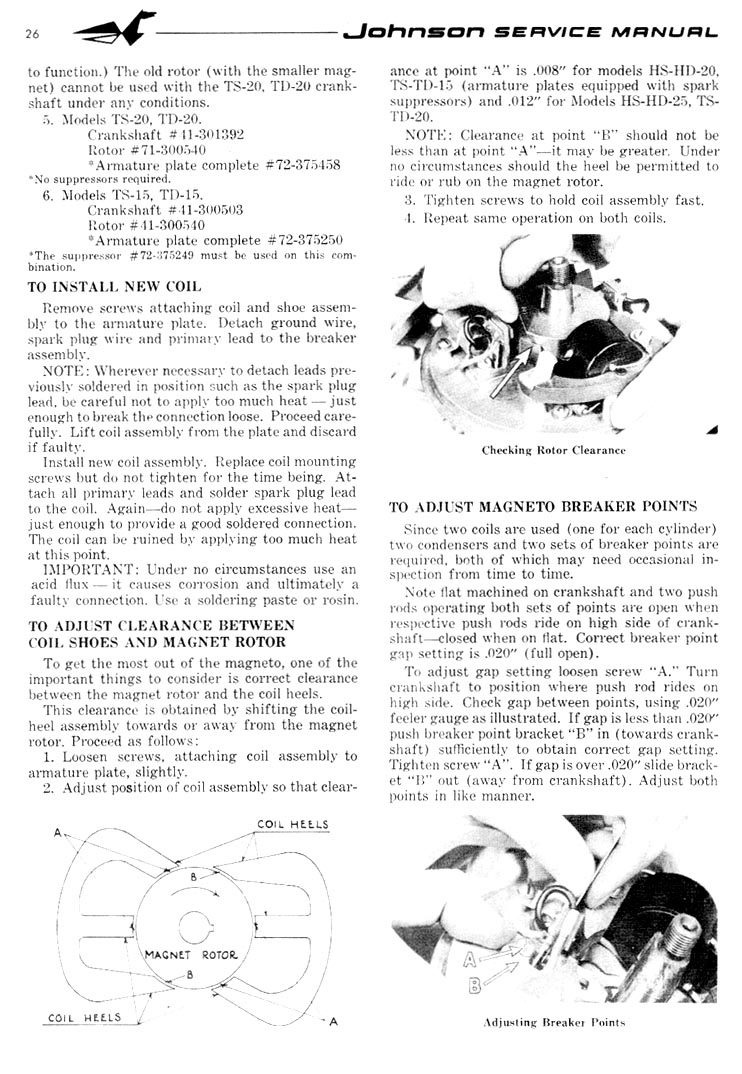

To set the coil laminate / heel gaps, I usually use three .010 strips

of shim stock to put between the coil heels and the magnetic rotor.Let us know how you make out.

Prepare to be boarded!

August 24, 2022 at 12:31 pm #264877Take the point apart, clean half at a time. 320 grit is a good

starting paper, but I always follow up with finer grits, 600,

800, or sometimes ever 1000 grit.The condensers should be replaced. It’s not worth messing around

with old condensers whether they test good or not, IMHO.Your coils probably are okay.

To set the coil laminate / heel gaps, I usually use three .010 strips

of shim stock to put between the coil heels and the magnetic rotor.Let us know how you make out.

Thanks. I have one new condenser installed and it didn’t fix the issue which is why I think it’s the points. I gapped the coil laminate at 0.012 and just made sure the heels did not hit

Appt with some bass tonight so I’ll pull the points tomorrow and clean them up and report back.

August 24, 2022 at 2:42 pm #264881I agree, take the points completely apart, degrease everything, and polish each contact individually. Do one set at a time and don’t lose any of the little insulators. I’ll bet you get spark.

Here are the rotor specs if you want to get it right. But they are very forgiving.

1 user thanked author for this post.

August 25, 2022 at 5:54 pm #264959I agree with Buccaneer and Frankr. After you get a good spark you will surely need new leather primer seals for the carb and instructions to install them. If so, you can contact me or just send $10.00 US cash (no checks or money orders) and a self addressed stamped envelope to me: Lloyd Lautner 9289 North Long Lake Road Traverse City Michigan 49685.

August 30, 2022 at 8:15 am #265274Well I used 400 to 1000 grit and cleaned up all the points. Re-installed and gapped points and coils and gave it a go. Fired up on second or third pull. Didn’t run very long but I still have to do a carb lean or rebuild.

Thanks for all the help

August 30, 2022 at 10:11 am #265276I agree with Buccaneer and Frankr. After you get a good spark you will surely need new leather primer seals for the carb and instructions to install them. If so, you can contact me or just send $10.00 US cash (no checks or money orders) and a self addressed stamped envelope to me: Lloyd Lautner 9289 North Long Lake Road Traverse City Michigan 49685.

Lloyd,

prob going to need some seals from you so keep an eye on the mailbox

-

AuthorPosts

- You must be logged in to reply to this topic.