Home › Forum › Ask A Member › Johnson TN-28

- This topic has 27 replies, 6 voices, and was last updated 5 years, 7 months ago by

crosbyman.

-

AuthorPosts

-

August 28, 2019 at 3:27 pm #182192

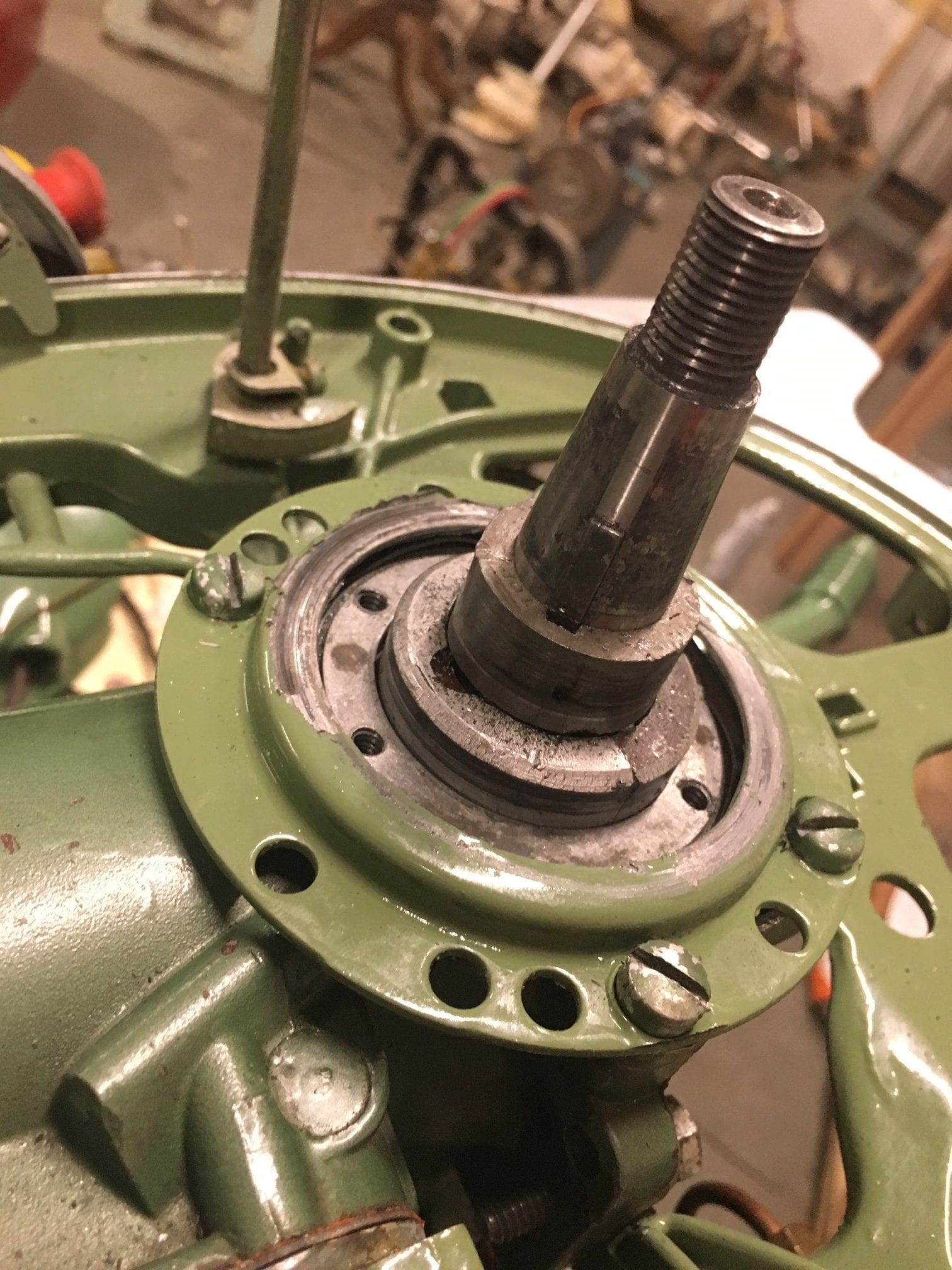

The copper washer is the only “spacer”. I think perhaps you do not have the mag plate seated properly. If memory serves, it kind of drops down when it is in the right position.

-

This reply was modified 5 years, 7 months ago by

Mumbles.

Mumbles.

August 28, 2019 at 4:40 pm #182203Not sure what you mean when you say “timing cam”. Maybe you mean to say the circular magnet? In any case there should be no washer or spacer under the magnet. The wave washer should be on top of the magnet as shown in the photo above. And there should be no “wave washer under the disc”?? Maybe that is what is pushing your magneto plate up too far.

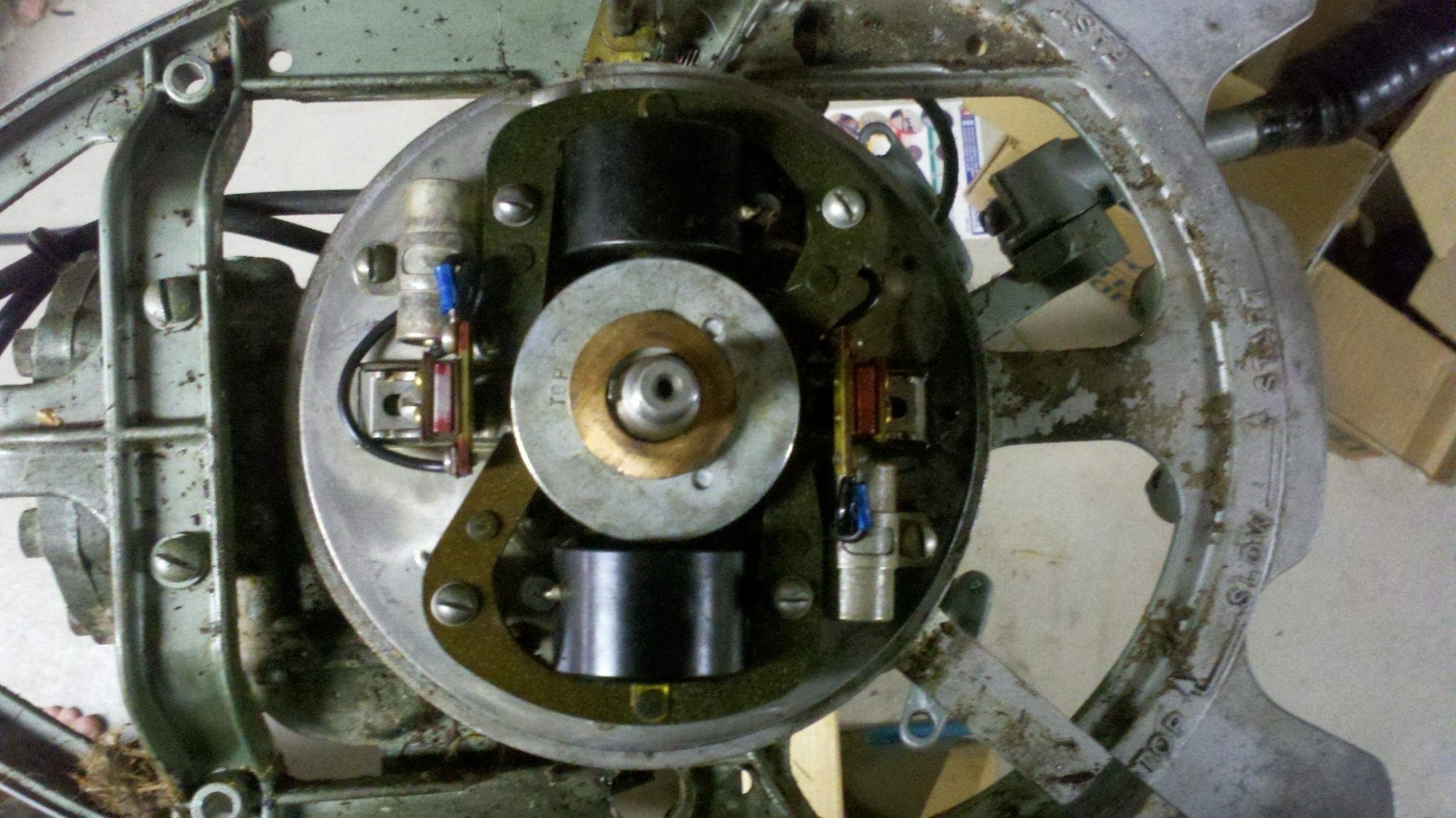

August 28, 2019 at 5:03 pm #182210Now I am completely confused. The photo of the magneto in page one shows a later magneto with the coil heels facing out towards the flywheel magnets and the photo above on page two shows an earlier magneto with the coil heels facing in towards the central magnet. Are we talking about a TN28 or some earlier motor??

August 28, 2019 at 5:50 pm #182212I did not post the pic above but I’m gonna post a few here of how I have it assembled , it is indeed a TN 28 and yes Lloyd I was indeed speaking of the circular magnet

It's a jungle out there.

-

This reply was modified 5 years, 7 months ago by

Mumbles.

Mumbles.

August 28, 2019 at 5:58 pm #182217Also Lloyd if you look back on the first page at the picture that has the red circle and arrow on it…..is this the correct way the carb linkage installs? I believe your the guy that sells the leather washers so I’m assuming that you know more than most about these lil motors. And thanks

It's a jungle out there.

August 29, 2019 at 9:31 am #182259Yes I am the guy that makes the leather primer seals. I am not absolutely certain, but I think your carb linkage looks correct. Been a while since I looked at one from the perspective shown in the photo.

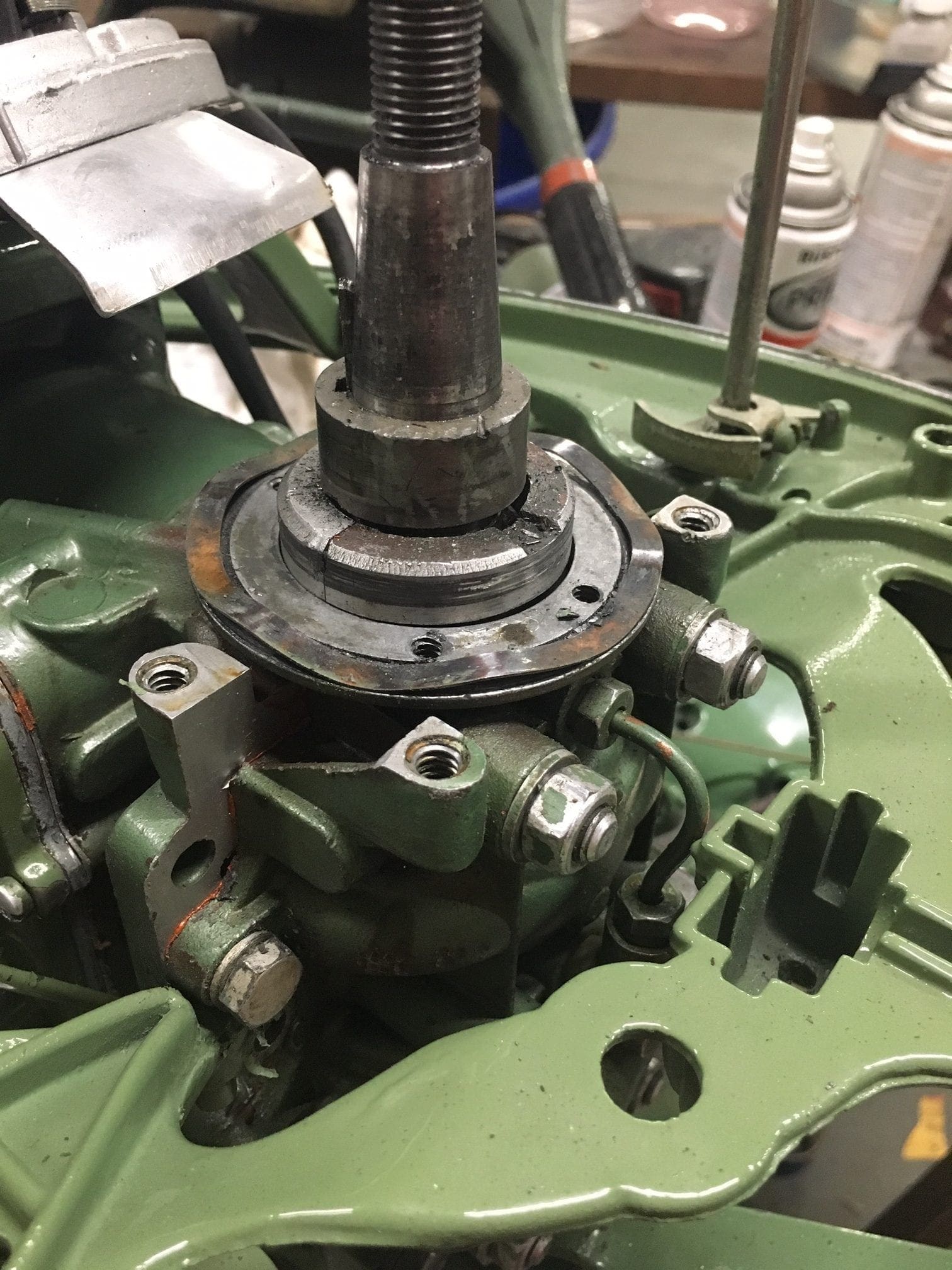

August 29, 2019 at 10:01 am #182260If it was easy then it wouldn’t be challenging and if it’s not challenging it’s not fun. I think I’ve got the rings seated good. No it didn’t start but I used a manual rope and pulled it about 100 times lol. Spraying fuel mix in the mixture valve. It would kinda sound like it was trying to hit but no smoke or nothing. Then I crossed the plug wires just to see and it coughed and sneezed more but after reading and tracing wires they were right the first time. I’m in the process of ordering the coil spacer ring as this is the second motor I’ve needed it. I put the wave washer and armature back on first and still couldn’t find a mounting problem. Tho it probably wasn’t the “right” thing to do, I took a grinder and hit the underside of flywheel where it was rubbing the armature and it’s not hitting anymore. I’ll get it eventually, it’s just a hobby.

It's a jungle out there.

August 29, 2019 at 12:03 pm #182268did you follow this procedure…

http://pochefamily.org/outboard/CarbService.html

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.