Home › Forum › Ask A Member › late ’80’s 9.9/15 flat plastic top carburetor

- This topic has 16 replies, 7 voices, and was last updated 5 years, 10 months ago by

fleetwin.

-

AuthorPosts

-

June 19, 2018 at 7:06 pm #10296

Rebuilt one of these for my ’89 Evinrude 15 hp. The plastic carb top has 2 small plastic sleeves that fit inside holes that are cast into the carb top. Looks to be some sort of vent.

My question is why have a sleeve that fits in an all ready existing hole? It is held in place by a fin that keeps it in place.

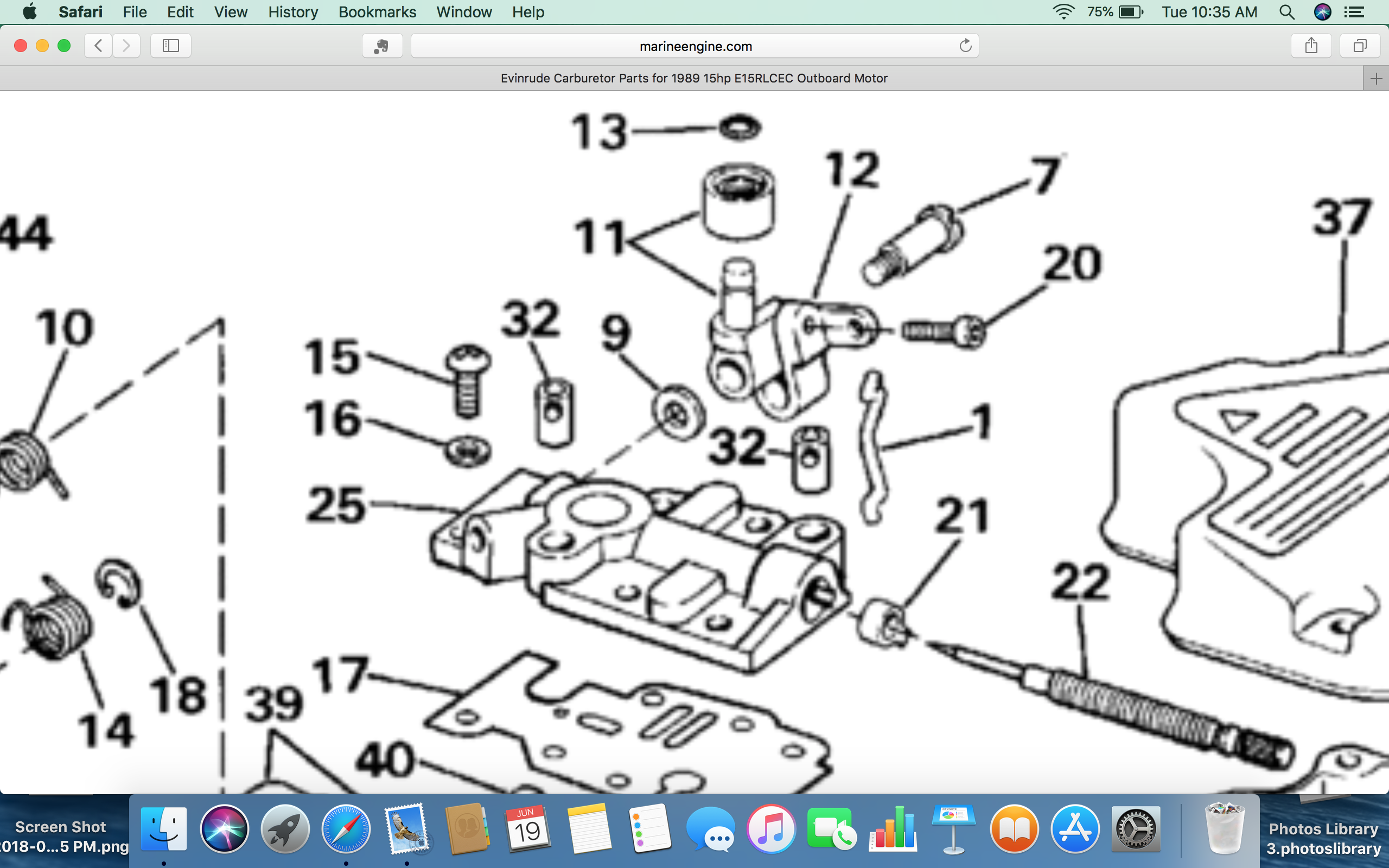

The part i am referring to is #32 in the diagram.

I have another one of these carbs on a ’89 9.9,and noticed that one of the sleeves is missing. When it’s running seems like the carb is not working right. Could this missing sleeve have any bearing on the carbs poor performance?

Thanks, Jim PSB"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 19, 2018 at 8:45 pm #78181It looks like they have a projection so they only go in one way. I would guess that they are metering sleeves. Put another one in the troublesome motors carburetor and see if it improves . . . 😎

June 19, 2018 at 9:08 pm #78184

June 19, 2018 at 9:08 pm #78184A word of caution on the plastic top…. be very careful with that, especially when working with the cam roller and throttle lever. One wrong move while working on it and it is easily broken! The new superceded top cover has improved and also comes with a big price tag. The last one i bought was $100.00 I can’t remember off hand on the sleeves? OMC put them in there so they need to be put back. Dan in Tenn will be along to answer that question..

June 19, 2018 at 9:32 pm #78189I give this a shot, but I not positive on this answer. The top has a lot of different parts (improvements?, needles for 10 & 14hp as well as 9.9 &15hp). That explains part of its $124 price. Still pretty high for CPS part. Look at the tech info on MarineEngine.com

The reason the sleeves are there is for tuning. The same top is used on the 5 thru 8hp motor. Notice the sleeves are different on those motors. Easier (cheaper for OMC/BRP) to change sleeves than make different tops. I’m pretty sure that’s the reason. Fleetwin would be a better source. Hope he comes back soon!Dan in TN

June 20, 2018 at 3:56 am #78202I dawned on me what the 2 holes and the sleeves are for .The 2 holes are for the screws that attach the lower half of the air silencer.As for the sleeves in the carb top, they may be for added strength where they pass through the plastic top .The are independent of the cover and take any torque and tightening stress instead of the cover itself, but still hold down the air silencer and carb top well.

They may be for some venting or metering too. The more i thought about it, i see it is well engineered, but still plastic to be careful with.

Jim PSB"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 20, 2018 at 5:40 pm #78215Yes Jim that is exactly it, it’s for the screws and support/strength.

June 20, 2018 at 6:29 pm #78217A tech once told me these plastic covers were prone to leaking air in. They can warp as they have five hold down screws and should of had six.

June 20, 2018 at 8:57 pm #78221Well guess I got suckered into that one? I considered support sleeves, but I wonder why they show a hole in the 9.9/15 sleeve & not the 8hp one? Turns out they are the same part number. I could have sworn I checked that out. Oh well so much for that theory. Told you to ask fleetwin.

Mumbles; OMC (engineers in general) constantly puts one less screw than is needed in assemblies. Don’t know why, but it’s either a cost thing or just for job security? Always have to come back & fix it later. Ask Fisherman6?

Dan in TN

June 20, 2018 at 10:31 pm #78231It warms my heart to see all these ex-Evinrude employees sharing this valuable information with us. I just feel bad that so many lost there pension in Evinrude’s bankruptcy . . . 🙄

June 21, 2018 at 6:52 pm #78266

June 21, 2018 at 6:52 pm #78266Well, I’m afraid to admit I wasn’t really aware that those plastic collars could be removed…But, it kinda makes sense that these little pieces help make castings/covers more universal to different engine sizes. The sad part of this whole thing is that these stupid carbs replaced one of the most bullet proof designs, reliable, and trouble free carbs ever…Oh well. The upside of this design is that all passages are easily accessed, no core plugs/lead shots to remove. The downside is the cheap plastic crap that breaks, warps, leaks, and is ridiculously expensive to replace. The early designs were horrible, leaky covers, rubber parts that dissolved the first time gasoline was added. The later designs were much improved though.

Watching OMC make the same mistakes the US automakers made years ago was very frustrating and depressing for me. We could have learned from their mistakes, but chose to just make the same mistakes, which rolled out the red carpet for Yamaha and Honda. I guess it all comes down to money and poor management. Buying up boat companies to ensure our engines got "packaged" on transoms was an idiotic scheme that just killed the boat companies and helped ruin our dealer organization. The Ficht engines were released way too soon, the final knife in our back.

I guess I am one of the lucky ones, will receive a little pension from the PBGC in a few years. It isn’t much, but I am very thankful for it.

I am hoping that BRP invests their money correctly to make sure the newer engines are durable, reliable, and easy to service. So many customers and dealers got screwed from OMC in the end, even the best and most affordable engines will be a "tough sell" for many years to come. -

AuthorPosts

- You must be logged in to reply to this topic.