Home › Forum › Ask A Member › Lauson outboard info

- This topic has 26 replies, 10 voices, and was last updated 10 months, 2 weeks ago by

PM T2.

PM T2.

-

AuthorPosts

-

September 11, 2023 at 7:12 pm #280486

Hello..

We are ow in receipt of a parts catalogue for our 1947 Lauson Sport King motor. We are looking for an exhaust pipe which we understand is part OB 447. Is there a particular place we can get parts for this motor? So far, we have found the correct spark plug but no doubt we will need more parts. Thanks

September 11, 2023 at 7:51 pm #280487Hello, we are also looking for a carb rebuild kit for our OB 410

September 22, 2023 at 2:58 pm #280877Hi gery i find ebay helpful and most of my lauson outboards come from Craigslist

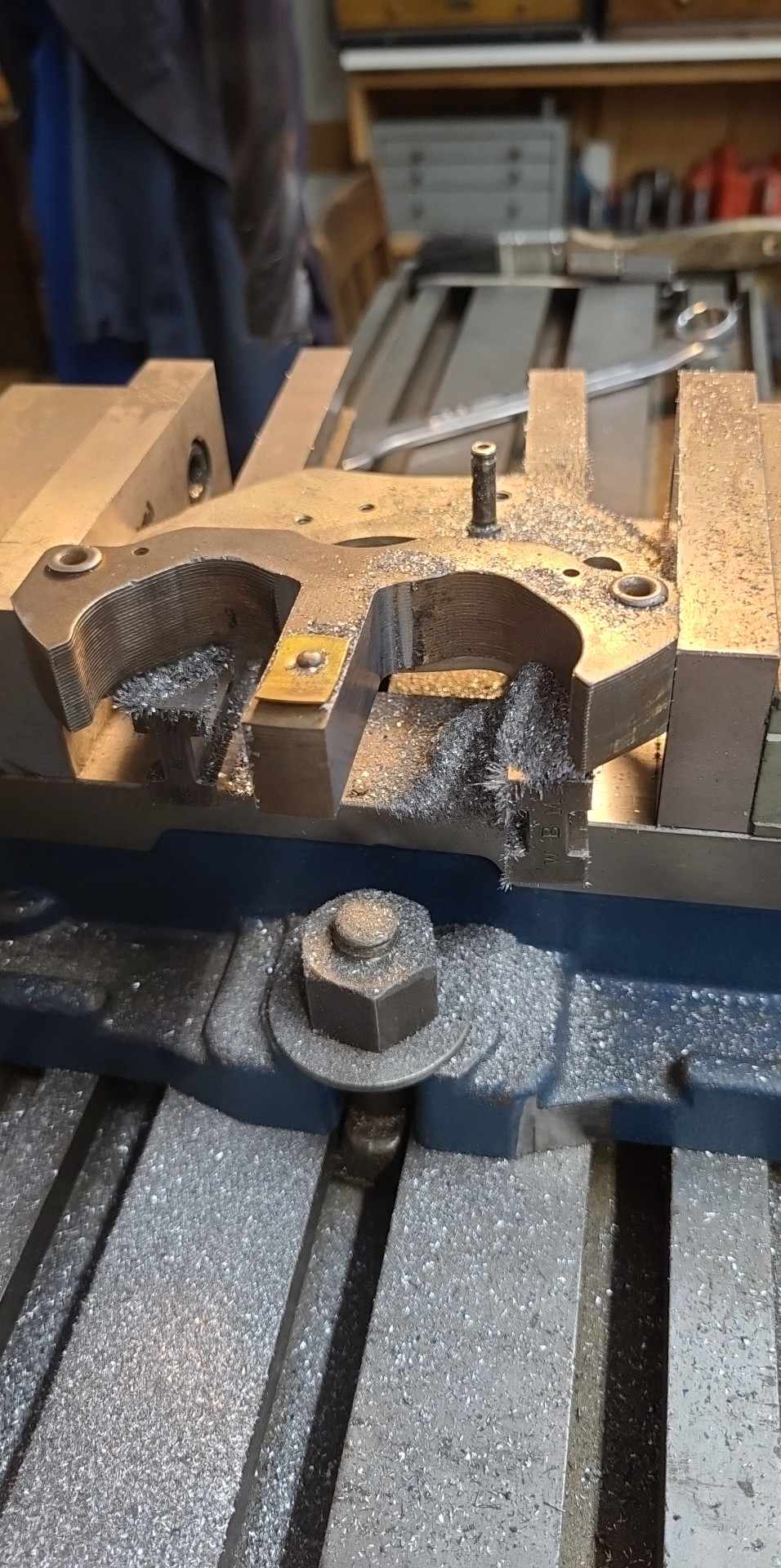

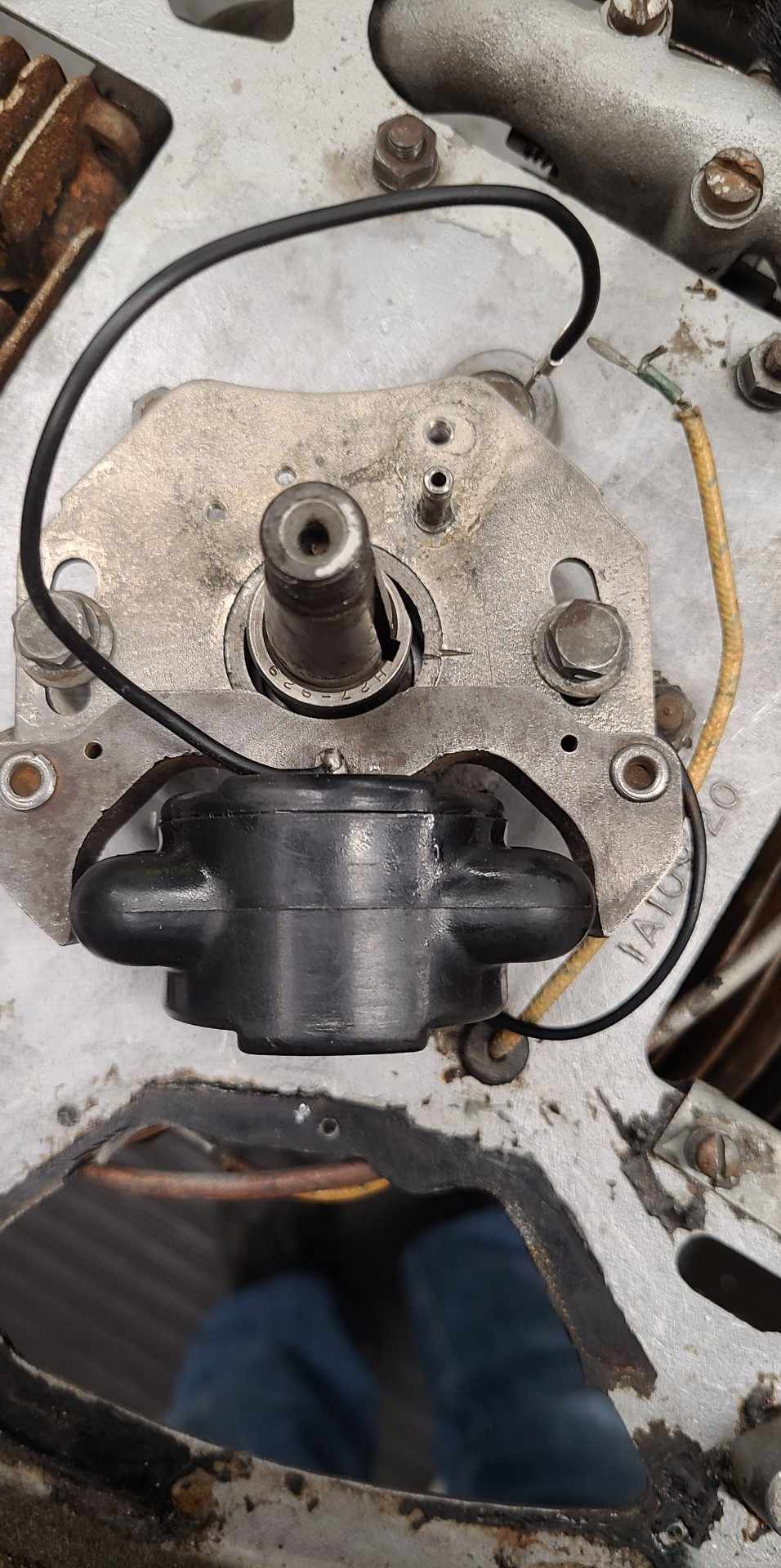

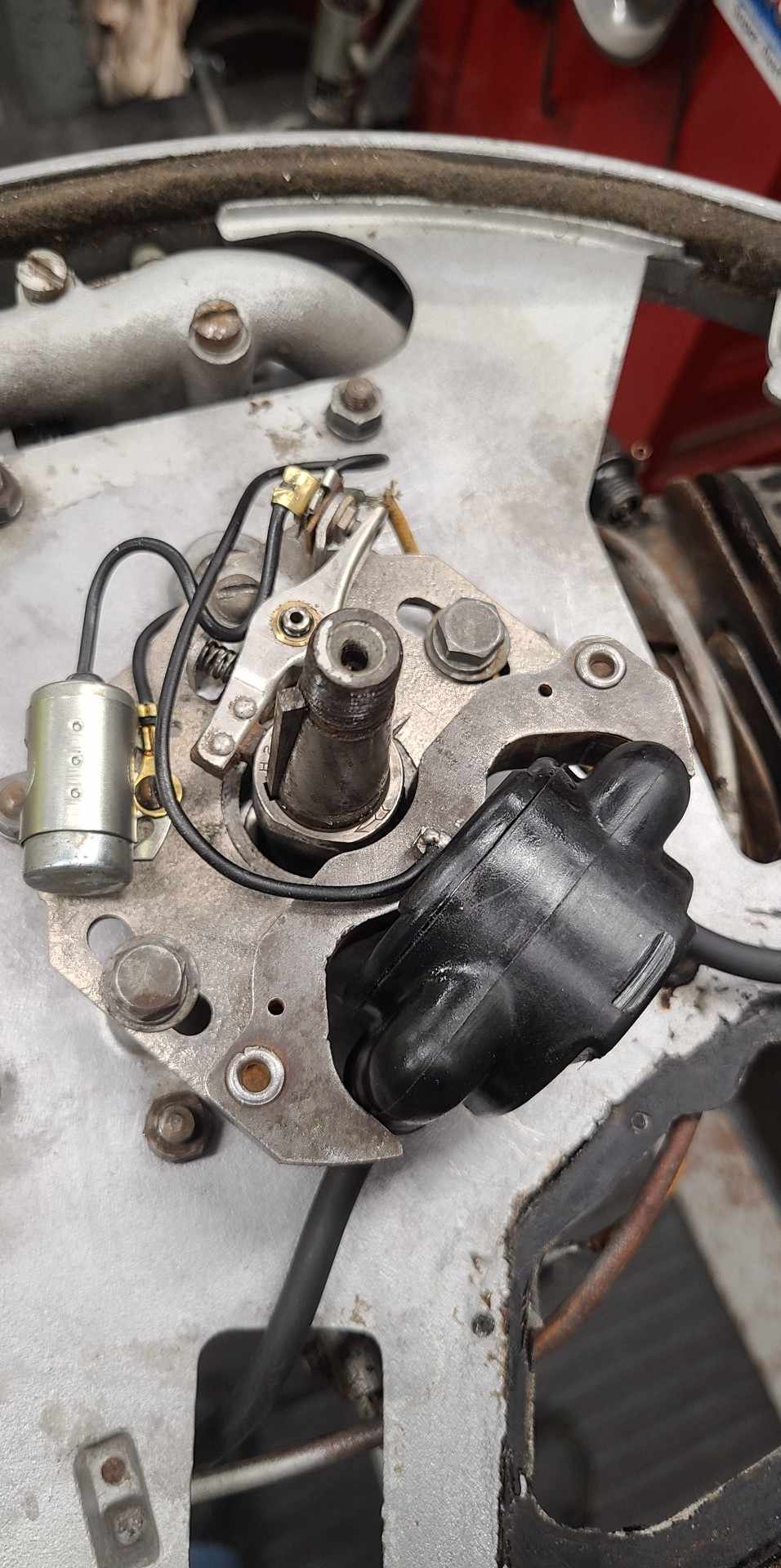

January 29, 2025 at 12:09 pm #293733I made one of those Pony engine coils fit onto a Lauson T-600 the other day. It takes some carving of the laminations to do it, but its not really hard to do. Hope this helps.

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

January 29, 2025 at 12:14 pm #293735January 30, 2025 at 11:37 pm #293765T2, nice job. One bit of info for those heading down this road, please. When you slimmed down the armature laminations, shaving even from side -to side, but how about the up and down? Did you take the laminations off of either the top or the bottom?… or even? Could make a difference for clearance of the coil to the mag plate or flywheel.

Joe B

January 31, 2025 at 1:33 pm #293767I took about .100″ off all four sides. I thought about taking .100″ off each side and .200 off the top of the centre core but I was concerned with fitting the coil over top of one of the crankcase cover studs. As it was, centreing the coil on the core allowed that to fit OK but then I had to relieve the ID of the flywheel so that it wouldn’t chew the new coil casing off. As it was, you can see evidence of a rub on the new coil. That should be addressed now and the flywheel won’t touch it anymore. I wrote a brief summation of this job with photos included. and it will be in the next edition of the GLC newsletter.

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

-

AuthorPosts

- You must be logged in to reply to this topic.