Home › Forum › Ask A Member › Mark 28, new thread

- This topic has 6 replies, 4 voices, and was last updated 9 years ago by

wedgie.

wedgie.

-

AuthorPosts

-

November 10, 2016 at 10:02 pm #5666

Decided to start a new thread on putting the powerhead back together.

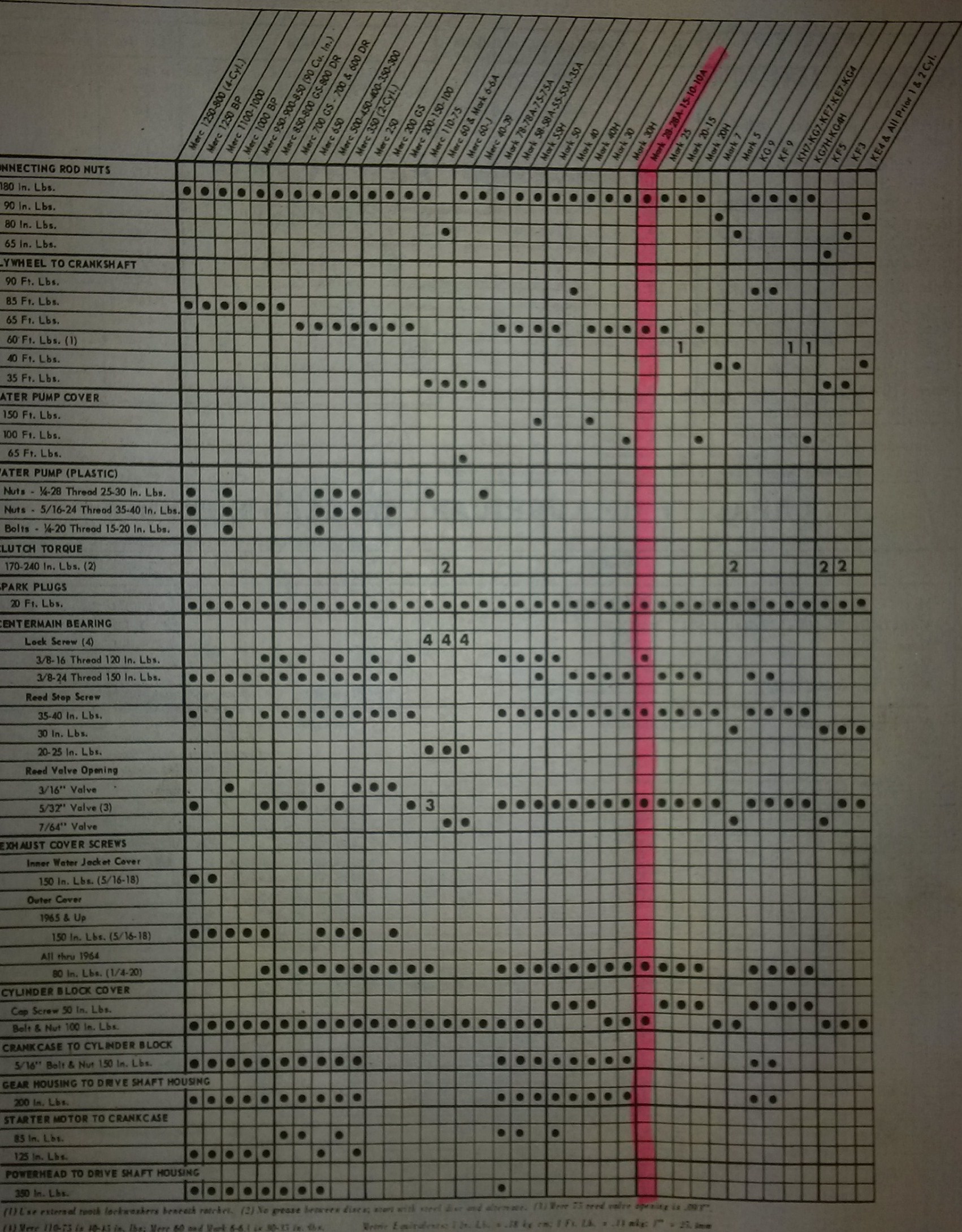

This torque spec chart from the Merc manual doesn’t have a value for the crankcase to cylinder block for the Mark 28 etc, or am I just not reading it right. I will assume since it is a 5 1/16 bolt and nut it is 150 in lbs ?

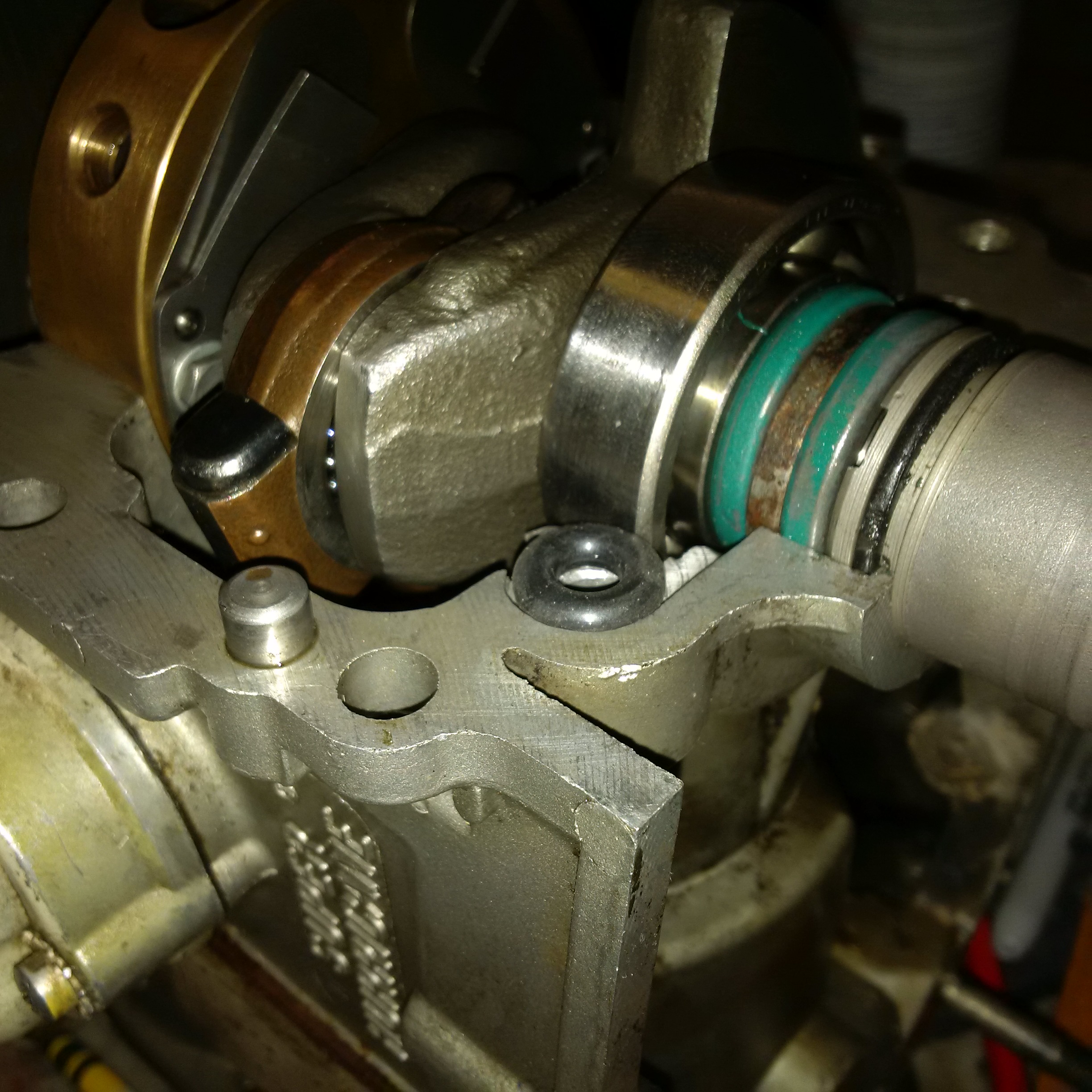

And I will also guess this is a double lip seal .

Which way is up ? the notch on the top or the bottom. Took it apart without making note of the notch some years ago

Does anyone have the dimensions , or cross reference for part number 25-25429 "o" ring , crankcase fastening screw. I have one that might work, but seems it may be too thick…or maybe not. Tried to get one locally ,but nope.

November 10, 2016 at 10:20 pm #47252the nut should start a few turns with your finger.

November 11, 2016 at 3:11 am #47269Thanks Dave and mercaholic.

Can’t find this circled part in the Mark 28 parts list though it is referenced in the service manual as "sleeve, protector- crankshaft . I thought I should replace the o ring as it is a little scarred so could use a part number to make it easy . Might be an addition from a later powerhead ? I’ll have to find some manuals to the later 20hp models .

November 11, 2016 at 10:42 am #47280

November 11, 2016 at 10:42 am #47280I know that omission on the chart is a mistake and it would seem that 150 in lbs is right. Do what you want and I am sure you will; but I have torqued a lot of crank cases and find that the 150 rating will sometimes strip out the nut or bolt. I like 120 inch pounds and don’t have any problems. This is right between grade five and grade two bolts, as shown in this chart:

https://www.boltdepot.com/fastener-info … orque.aspx

Edit: And yes, my torque wrenches get checked.

Long live American manufacturing!

November 11, 2016 at 9:12 pm #47301Thanks Bill. Sometimes I do what I want if I’m allowed to 😉

I’ve noticed a few typo’s and pictures swapped around in the service manual . I will take your advice !

November 18, 2016 at 5:49 pm #47632Wedgie,

nice build! You will enjoy the power with the 200 block. Be sure to get the crankcase o-ring correct. Then Enjoy!!

JeffDecember 11, 2016 at 8:09 pm #49019Day off today, so back to the Mark 28 re assembly with parts from Joe Poole Jr.

Reading the pre 1965 manual, it says set the reed stops to 5/32 0r, .1562, but it doesn’t tell me how. it also says to set the reeds so there is no "pre load" with a maximum gap of .007 . When looking closely at the reeds, some are sitting tight to the center main bearing (with a light film of oil sticking them down). Again, this powerhead has been opened before I got it, so I’m proceeding carefully.

Thanks

-

AuthorPosts

- You must be logged in to reply to this topic.