Home › Forum › Ask A Member › Mark 40H Cylinder Block stud missing

- This topic has 7 replies, 5 voices, and was last updated 8 years, 10 months ago by

westwind.

-

AuthorPosts

-

February 19, 2017 at 3:08 pm #6378

Hi All,

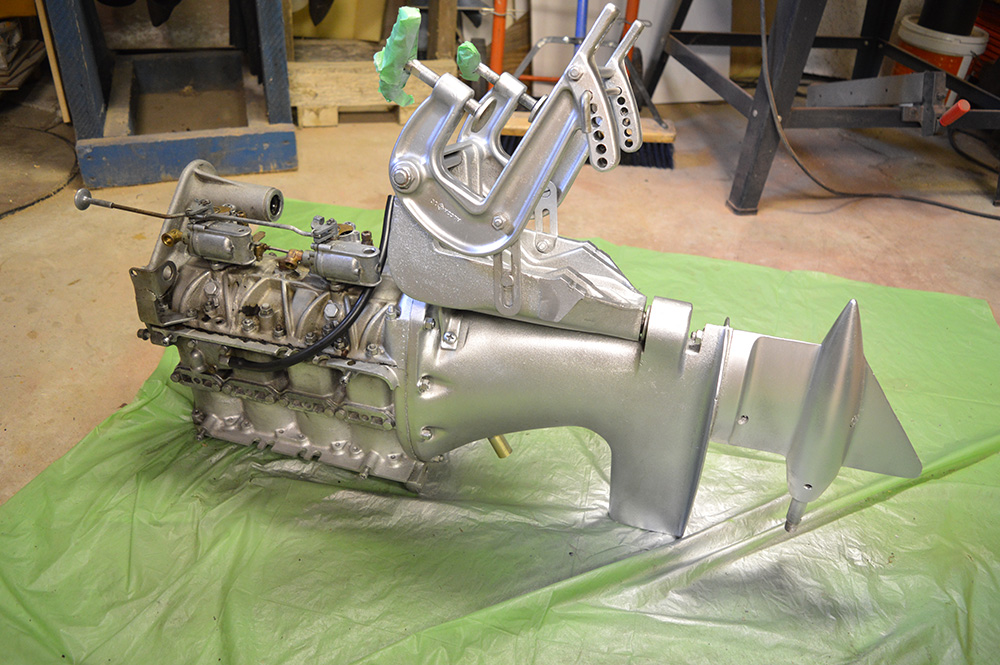

I am still working on the restoration of my "barn find" Mark 40 H. The coil and points have been replaced on the Magneto (Thanks Don!) and now I have spark back on all four spark plugs. I am currently getting the bolt hole areas of the cowling re-welded using the services of an aluminum welder in the Barrie area. (No more JB Weld) See my other posting here: https://aomci.org/forum/viewtopic.php?t=10651

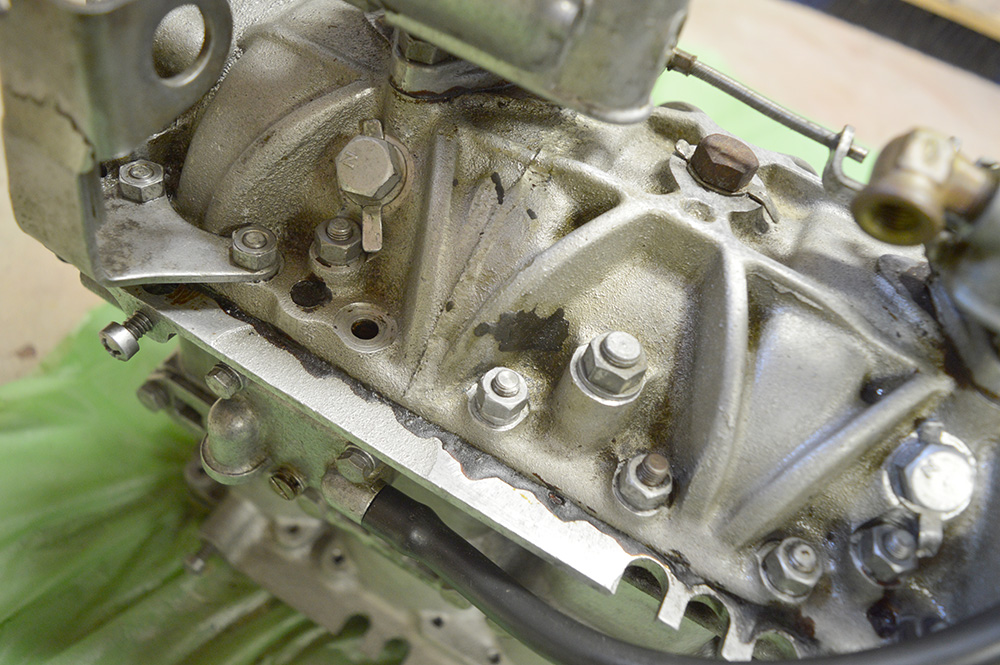

With the motor almost completely disassembled now I am turning my attention to cleaning up the cylinder block. While inhaling way too much carb cleaner I noticed that "one of the studs was sheared off just below the surface near the fuel filter bracket. I have attached a few photographs for reference. My question is…. is this going to be an issue? I don’t particularly want to re-tap the threads. Will the motor work with the bolt missing? The threads of the sheared off bolt are still embedded in the crankcase assembly. Suggestions please?

Chris

February 19, 2017 at 3:52 pm #53266Are you referring to the spot where it is covered over by the brownish sealer type of stuff? Or the spot-faced area where there is no nut and washer?

Best,

PM T2He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

February 19, 2017 at 5:00 pm #53271The spot covered by the sealer is the crankcase dowel pin…no..I am referring to the spot faced area…..with the missing nut and washer.

February 19, 2017 at 5:08 pm #53273yeah I was going to say the one spot was a dowel…. the broken stud, you "could" possibly get by with leaving it as-is… and maybe putting some sealer in the open cavity…. The casting is probably rigid enough in that area that it doesn’t present any crankcase leakage issues….. but if it was my motor, I’d fix it.

Just an opinion eh

Best, PM T2

He's livin' in his own private Idaho..... I hope to go out quietly in my sleep, like my grand-dad did..... and not screaming, like the passengers in his car...

February 19, 2017 at 6:20 pm #53281drill it and tap it foe a 1/4 if you are uncomfortable with tapping it out to 5/16. just a thought. you have more room for error. and put in a bolt and not a stud.

PS don’t forget to bend your tabs on the reed cages and main bearingsFebruary 19, 2017 at 11:18 pm #53295Thanks guys! I think I’ll tap it out!

Chris

February 20, 2017 at 2:05 pm #53323Barn find? Man…I gotta start lookin in some better barns. All I ever find is old ratted out TD 20’s froze up by mouse pee….

February 20, 2017 at 2:55 pm #53328It’s more work but less risky than drilling. Disassemble it further and remove the broken piece. Weld an nut to the stub, or weld a washer to it if it is too short and then weld a nut to the washer.

-

AuthorPosts

- You must be logged in to reply to this topic.