Home › Forum › Ask A Member › Merc fuel lines

- This topic has 9 replies, 5 voices, and was last updated 9 years, 1 month ago by

sailor58.

-

AuthorPosts

-

February 22, 2016 at 8:30 pm #3695

I need to make new fuel lines for my Merc 800 DR project. Anyone have someone that does these? Or knows where I can purchase the fittings?

LarryFebruary 22, 2016 at 9:04 pm #32349http://www.vintageoutboard.com

Talk to Doug

Travis

Travis

AOMCI VP Communications

AOMCI Webmaster

webmaster@aomci.orgFebruary 26, 2016 at 2:10 am #32520Larry,

First thing is to NOT throw away any old fittings. Remove all the hose material from the fittings. After getting the fittings very clean find copper tubing that just fits over the original tube. Use wet & dry sandpaper to get the pipe very clean. Slide your piece of copper tubing over the short factory tube after coating it down with electronics flux. Comes in a can about the size of chewing tobacco. Clamp the fitting in place using very little space on the fitting. The clamping will act like a heat sink & take away heat, we don’t want that. Get it smoking hot & right at where the new tube meets the old touch the solder to it. If hot enough the solder will be sucked up inside the two tubes & get off the heat fast. Do NOT touch or move the fitting until it has cooled & turned dull silver. After you have added 1/2" of pipe on the end the fuel line rubber tubing will slide on all the way to look like factory fittings. Be sure to buff them up to look nice too. A guy can run clear tubing between the three carbs to see if the pumps are working. Don’t worry if you see bubbles too. Keep that 800 it is one of a kind & very fast for an early 6. I use black zip ties to crimp the tubing to the fittings. Saves you money & looks good too!! 😀February 26, 2016 at 11:40 am #32524February 26, 2016 at 10:34 pm #32531Plan "B" from a ‘cheap’ displaced Cannuk in Raleigh.

Since most of the fuel lines are now NLA I reuse the existing fittings.

I cut off most of the ‘crimped’ portion of the original connection and remove and clean off the remnants of the original fuel line. Then I ‘recrimp’ the remains of the fitting using a flaring tool, and slightly ‘flare’ the end of the copper tubing. Some new 1/4" fuel line and some good stepless ear clamps and away you go. I have pressure tested these connections up to 25 PSI and they hold pressure perfectly.

February 26, 2016 at 10:40 pm #32534February 27, 2016 at 4:13 am #32541I sure like your clamps, Where do you get them? My idea is the same except I add a little more copper pipe on the end. The great flare you use is the best as you tested up to 25 pounds & no leaks! That is better than factory I believe. Are you using stock carbs? I went to AJ54 carbs to have a fixed high speed. The main jet is still.055 & the venturi still is 7/8ths so it should be an easy swap……should be!! I didn’t want to adjust the hi speed jets wide open with a tiller. My Mk 30 has the Mk 55 block for 40 hp Mk 30. Just swap cranks & your ready to go!

JeffFebruary 27, 2016 at 12:57 pm #32545Forget where I bough the clamps on line, some ‘speed’ shop. My Mark58 has a pair of KA2A’s with the fixed jets, .063 if I recall correctly.

February 27, 2016 at 6:00 pm #32562Yes,

that sounds correct, .063 jets were used in many carbs. If you look on the very bottom it will show the venturi size too. The KA2A carb seems familiar

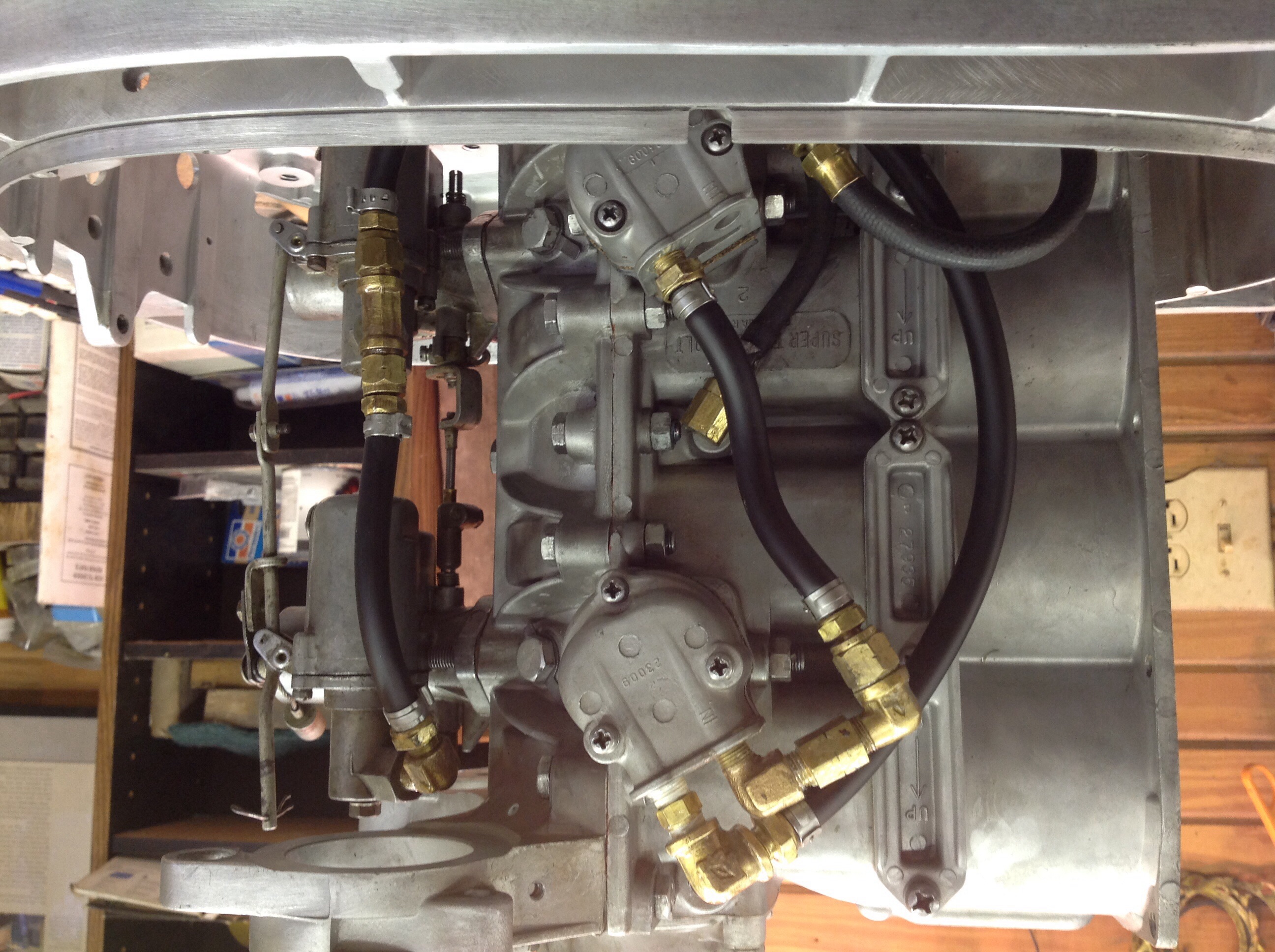

I think my Merc 200 has that carb. They should work very well. My Mk 55 block is going on a Mk 30 frame so I’m being conservative with the power.February 29, 2016 at 8:23 pm #32685I ended up going here. http://fittingsandadapters.com/. I was able to buy all the fittings and ferrules from them. Came to $35 shipped. I bought 6′ of 1/4" fuel line from my local auto parts store for $10. I changed Mercury’s proprietary and NLA disconnectable fittings to SAE 45 degree flare fittings. I made a swaging fixture to crimp the ferrules. The fixture uses two removable dies that I made also. If I could figure out how to post pictures I would post some. I think that I would have changed to the flare fittings anyway as they are a better system. There was ample evidence that the Mercury fittings had been leaking.

Larry -

AuthorPosts

- You must be logged in to reply to this topic.