Home › Forum › Ask A Member › Merc KD4

- This topic has 9 replies, 6 voices, and was last updated 2 years, 2 months ago by

green-thumbs.

-

AuthorPosts

-

December 15, 2022 at 6:37 pm #270011

installing new rings in a KD4. What is acceptable ring gap?

December 16, 2022 at 10:02 am #270023The old rule I remember, but from “automotive”, was .003 per 1″ of piston diameter.

Hence, a two inch piston, .006.

That would be acceptable minimum gap though……. How large a gap is another question.Prepare to be boarded!

December 16, 2022 at 7:57 pm #270040Everything You Need to Know About Ring Gap! (wiseco.com)

-

This reply was modified 2 years, 2 months ago by

fifty20ne.

fifty20ne.

December 16, 2022 at 9:44 pm #270045Careful, with that wiseco formulation, something is “fishy”, or my math is way off.

0.04 % of say 2 inch bore is only 0.0008 inch, way too small

and in the other interpretation of the formula … 0.04 X 2 inch = 0.080 inch , way too big

Joe B

PS, I just looked at air cooled small engine repair manual , typical ring end gap listed is 0.010 to 0.025 … and that is for air cooled engines, I think that on water cooled engines the tighter end of the range would be OK

-

This reply was modified 2 years, 2 months ago by

joecb.

December 17, 2022 at 8:26 am #270056December 17, 2022 at 10:17 am #270058Careful, with that wiseco formulation, something is “fishy”, or my math is way off.

0.04 % of say 2 inch bore is only 0.0008 inch, way too small

and in the other interpretation of the formula … 0.04 X 2 inch = 0.080 inch , way too big

Joe B

PS, I just looked at air cooled small engine repair manual , typical ring end gap listed is 0.010 to 0.025 … and that is for air cooled engines, I think that on water cooled engines the tighter end of the range would be OK

-

This reply was modified 2 years, 2 months ago by

joecb.

My rule of thumb has always been .003 to .004 per. inch

when not having a factory spec.

I believe 1% of an inch in .000 is .010

I interpret fifty20ne’s speck. to mean 4/10 of 1 % to

5/10 of 1 % which would be .004 to .005 end gap per. inch.

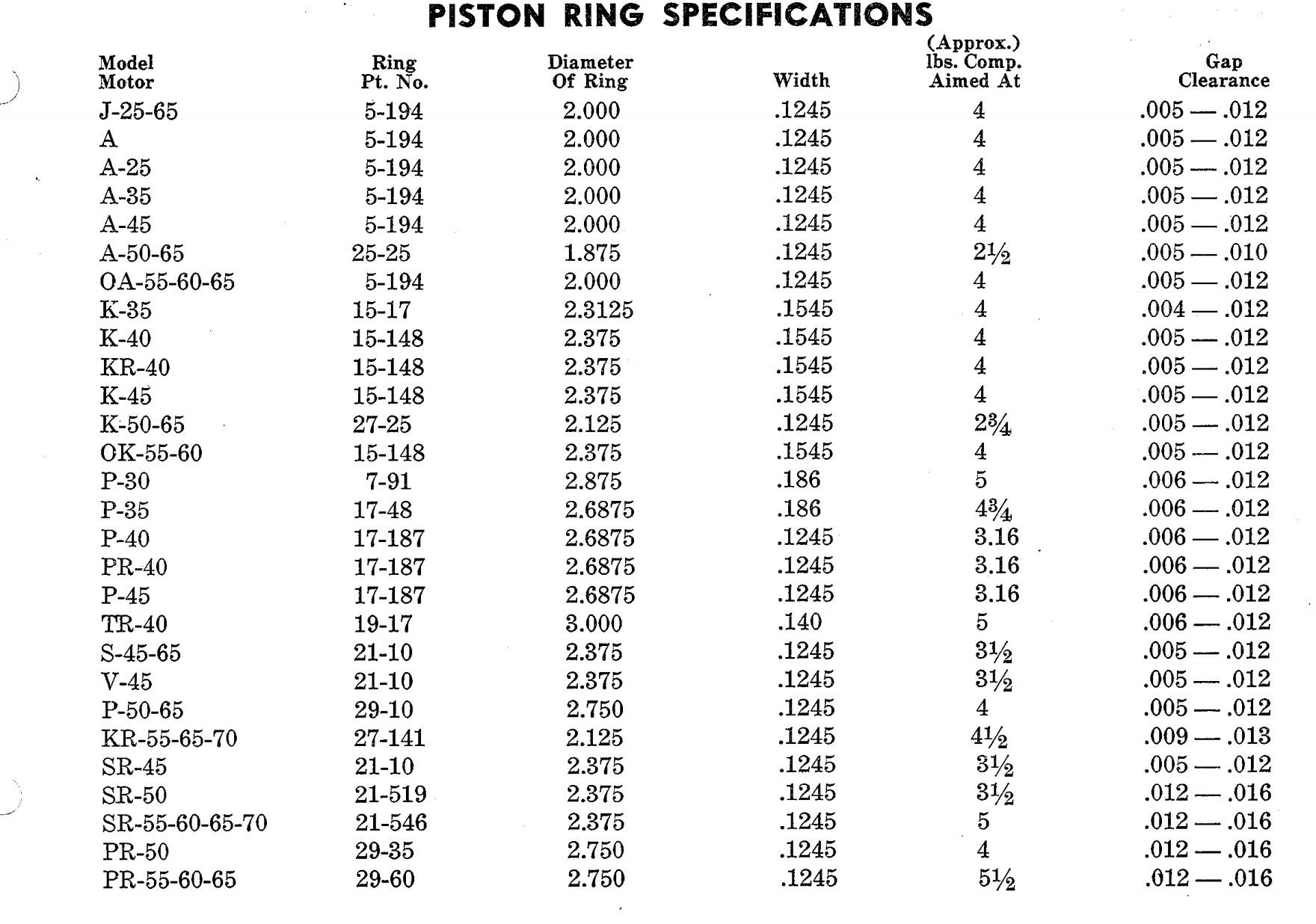

After seeing Bucks chart I will now use this as a guide

for 2 strokes when not having a factory spec.

“Typical ring end gap listed is 0.010 to 0.025 for air

cooled engines”. ??????

I can imagine what a 10/1000 to 25/1000 end gap would

apply to.

Tubs.A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

This reply was modified 2 years, 2 months ago by

Tubs.

Tubs.

December 17, 2022 at 8:35 pm #270074My minimum gap is .008. To tight?

December 17, 2022 at 9:46 pm #270075Ref the chart that Bucc posted, your 0.008 looks just right

Joe B

December 17, 2022 at 9:59 pm #270076not to beat the dead horse… Tubs’ calculations are correct. 4/10 of 1% is 0.004. But. look again at the post in question, it shows 0.04% or 4/100 of 1% = 0.0004 ( for a 1 inch piston)

So, It looks like the “wesco” post just had the got the decimal point in the wrong place…typo!

Joe B

1 user thanked author for this post.

December 18, 2022 at 1:11 pm #270088All good to know and useful information, however one has to start with a good cylinder. All wasted if cylinder is excessively worn or scored. Fortunately, the modular design of the Early K Model Kiekhaefers cylinders can be removed and replace with better cylinders from a parts motor, Boring to an oversized is not an option as oversize, rings and pistons were not offered and were not needed. Mercury did it their way.

Once a good cylinder AND piston are in hand then it is time to set ring end gap.

Louis

-

This reply was modified 2 years, 2 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.