Home › Forum › Ask A Member › Mercotronic Model 98 and Model 9800 Information

- This topic has 47 replies, 10 voices, and was last updated 2 years ago by

29Chev.

-

AuthorPosts

-

March 19, 2023 at 10:26 am #274126

Thanks for the readings – blue band = 6 (first digit of ohm value), grey band = 8 (second digit of ohm value) , the black band = 1 (multiplier) and the silver band is the tolerance which is 10%. So the resistor value should be 68 ohms with a tolerance of 10% (6.8 ohms). A measurement reading of 74.8 ohms shows it is right on the edge of the higher resistance tolerance but should still work ok. This is all assuming that it is the equivalent of the shunt resistor shown in the schematic which I cannot say for exact certainty.

The capacitor readings that you show on your meter are in nF (nanofarads) looking at your pictures. Capacitors (and condensers) usually found in ignition circuits can be measured in nanofarads or microfarads. Smaller capacitance values will often be stated as picofarads and if you do a google search you can find conversion calculators online to enter one reading value and have it converted to the other two values as the multiplier factor is all that is changing. A reading of 95.5 nF is equal to .0955 uF (microfarad) and looks like you are measuring a new capacitor with a value of 0.1 uF so the meter may be off a smidge or the test leads may not have been zero’d before taking the reading. Not criticizing – just observing as some capacitance meters need the leads to be connected together and zero’d before doing a test on the actual capacitor so any capacitacne in the meter leads is removed from the measurement. The reading you got on the 0.15 uF capcitor in the Mercotronic of 196.5 nF – this would equate to a value of 0.1965 uF. If we compare the two readings that you got on the two capacitors and assume the first reading on what looks like a new capacitor of 0.1 uF is off just a smidge then the one in the Mercotronic may be a little off its correct value at almost 0.2 uF. You could use a scotchbrite pad on the two leads of the capacitor in the Mercotronic to remove any tarnish on them as that could affect the reading accuracy as well. When measuring electronic components connection cleanliness is a must to obtain accurate readings. Given the age of that capacitor you could consider replacing it with a new one of the same rating and value but that is entirely up to you. I have experienced capacitors (which are the same component as condensers electronically) test good or just slightly off value using a tester such as you are using and still be bad in an ignition circuit as stated by the other poster in the previous post. The oscillations that occur in a primary ignition system when the ignition coil fires can result in voltage peaks of close to 200 volts – only happens for a brief moment in time during each firing but these voltage peaks can jump across the condenser connections internally if the condenser is starting to fail or is partially shorted. Given the value that your meter is showing the original condenser may be partially shorted internally.

One thing you could try is to use a pair of side cutters and clip one lead about halfway between the capacitor body and the connection where it joins to another component – before doing this clean the lead with a scotchbrite pad or fine emery paper so it will be clean to solder back together afterward if you do not plan on replacing the capacitor. This would remove it out of the circuit temporarily and you could then use two test leads to connect a new capacitor of the correct value and rating 0.15 uF 400 VDC (or condenser) to the circuit where the capacitor is now connected and see if the meter reading changed when testing a coil. If it does then this would indicate the capacitor is probably affecting the meter reading. If the meter reading does not improve then I would check for resistance in any connection point in the circuits that go to the meter terminals (such as the switch terminals or solder or crimped joints). If the new condenser temporarily connected does not change the meter reading and you chose not to replace the original condenser the lead ends that you cut with the side cutters can then be placed back together end to end and a thin strand of wire can be wrapped around several times on the lead on each side and over the join area – this will enable you to solder the lead back together easily and insure a good joint as the wrapped strand of wire will allow the solder to flow and form a good connection. Any electrical connection should be done with a rosin core solder or equivalent – do not use acid core solder – you probably already know that but just thought I would mention it.

Hope this makes sense and helps you

Replacing the capacitor makes the most sense to me at

my skill level. A search for a 0.15uf 400v capacitor

produces a verity of components. I’ll need some

direction to obtain what is correct.

Tubs.A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

March 19, 2023 at 10:34 am #274127Where did you source the new capacitors you show in the pictures? Since I am located in Canada if you can provide me with a website link to where you wish to source a new one from I may be able to help you select one that will work. As long as the capacitor can physically fit and connect to where the original one was connected it should work as long as the value and voltage rating is correct. A capacitor with a higher voltage rating may be used if you have one on hand that is 0.15 uF and a voltage rating that is the same or exceeds the original value of 400 VDC.

March 19, 2023 at 11:50 am #274138

They came from eBay. Got them to substitute the condenser in a point ignition

as has been a topic here from some time. They didn’t work. Went back to

condensers as I know what to buy.

Tubs.

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

March 19, 2023 at 2:29 pm #274140You could replace the capacitor with an ignition condenser as long as the microfarad value is the same. Might have to go through the various manufacturer condenser listings in the Mercotronic manual to find one that is .15 uF value and figure out a way to mount it where the original capacitor is or you could also mount it where the contact set is as long as the lead is connected to either the black or yellow wire and the case of the condenser connected to the other wire looking at the pictures you posted. Just a suggestion if you happen to have one on hand that is 0.15 uF value. Then you could just cut one of the leads on the original condenser and bend and tape one of the cut leads and just leave the old condenser where it is for a reference of the correct value in the future.

I would suggest purchasing a condenser from a reputable electronics component supplier rather than off of ebay – just my personal preference as you do not know whether the ones on ebay are ones that a manufacturer or supplier dumped because they were out of spec or?? and as a result the quality may or may not be what you desire for use in a test tool.

Here are a couple of links to a capacitor that should work to replace the one on the Mercotronic and these are only suggestions – you may have an electronics store or supplier close to you that can also supply a similar capacitor. The other thing to keep in mind is that replacing the capacitor may not fix the problem of the low meter reading. Having said that if the capacitor is original it would be wise to replace it from an age point of view the same as if a customer had an engine the same age as your Merctoronic and still had the original condenser you would probably recommend replacing the condenser because of the age of it as good preventive maintenance.

March 19, 2023 at 8:21 pm #27416685 each cents free shipping with Prime

Joining AOMCI has priviledges 🙂

March 20, 2023 at 11:31 am #274187

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

1 user thanked author for this post.

March 22, 2023 at 12:52 pm #27429229 chevy,

Thank you very much!! It’s hard to find another electronics person to converse with. I’m self taught in electronics, most of my working time was with commercial/ industrail electrical except hi-voltage neon transformers, 15,000 volts but milli amperes. I’m going to study your post on mofets to learn, thank you!

Metal oxdide field effect transistors or something like that. I’m very blessed to still be here. thank you. Iv’e always been interested in electrical learning the hard way getting knocked across the room in the 3rd grade touching a old B&W flyback transformer.

Jeff

1 user thanked author for this post.

March 22, 2023 at 6:40 pm #274314I started off about age 10 learning about electronics, am self taught and I find at 67 years young I am still learning and enjoying it even now even though the hands aren’t as steady and the eyes not as sharp. If you have any questions about the Mosfets or the vibrator circuit you can post them in the thread on the Smokestack website or send me a PM there.

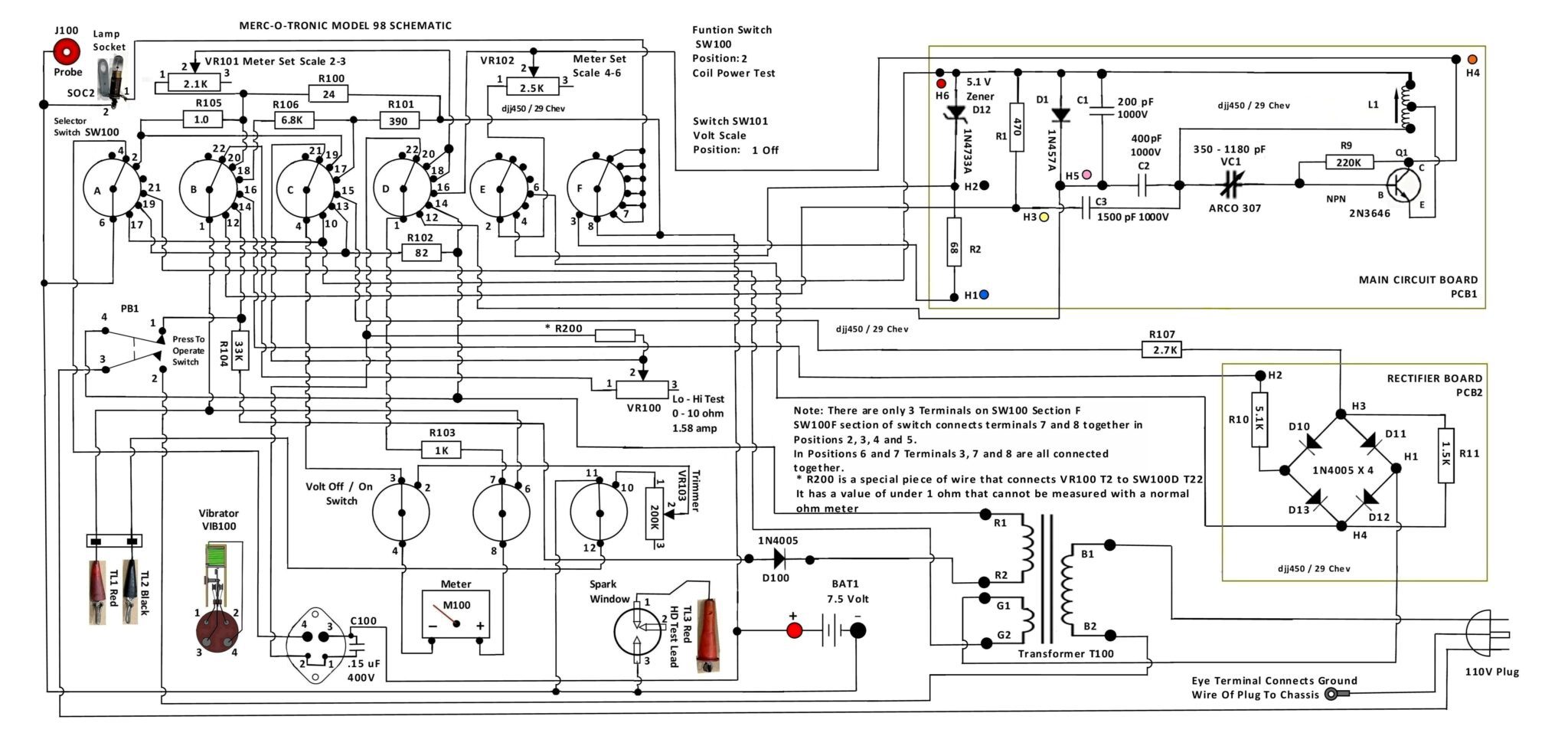

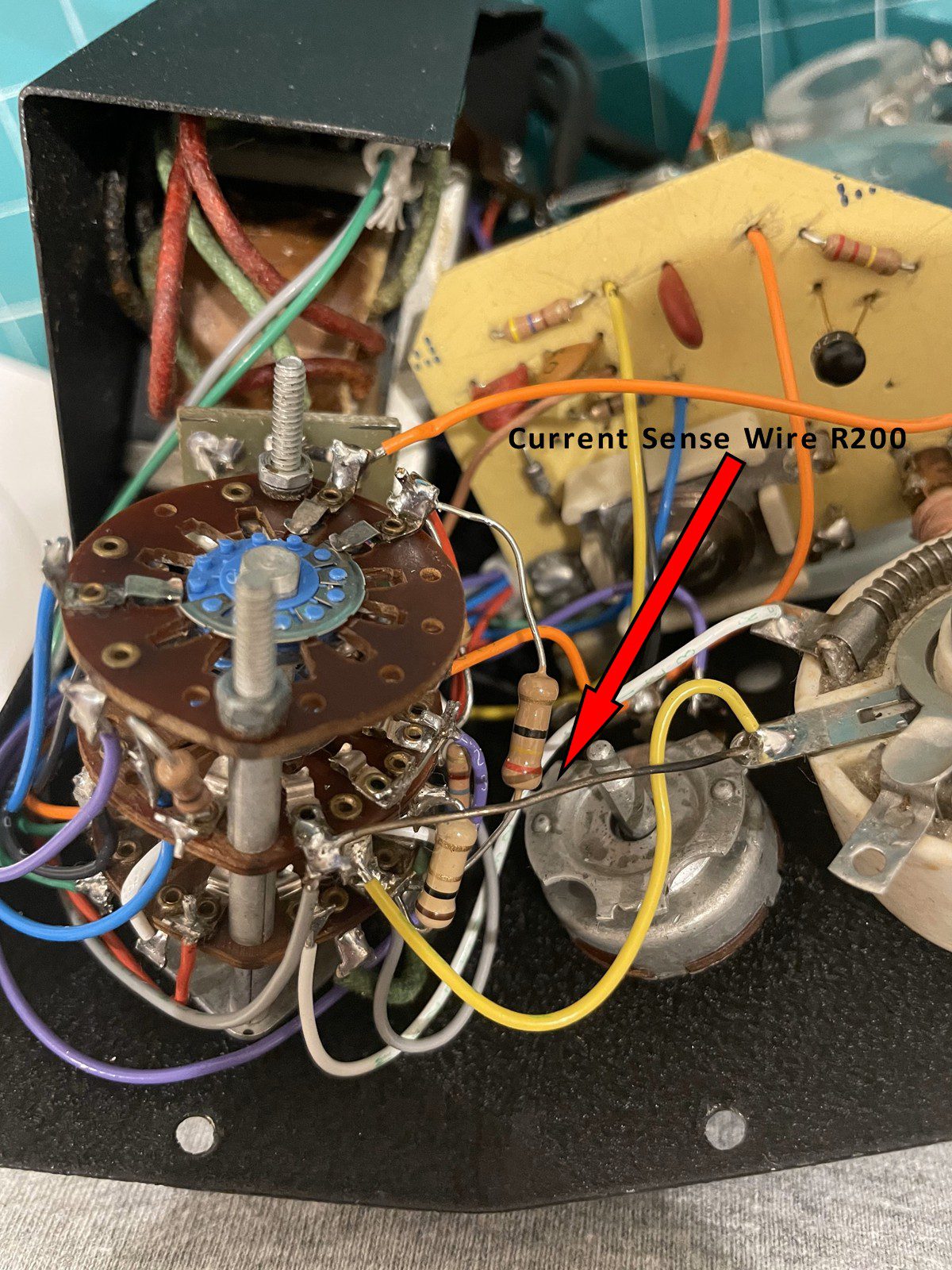

March 22, 2023 at 6:49 pm #274315It has come to our attention that there is a small error in the schematic that I posted for the 98 during coil test mode so I have updated the schematic drawing so it is correct. It turns out that on the 98 and the 9800 they used a special piece of bare wire (looks like ordinary wire) as a very small value resistor to act as a shunt resistor for the meter circuit. I figured I had better mention this in case someone decides to copy the schematic as originally drawn to try and make a coil tester. We have tried to measure the resistance of the piece of wire but it is too low to measure using an ordinary ohm meter. My educated guess would be that it has value of approximately 0.015 ohms but that is only a guess. I have also attached a picture of the wire as it is located on the model 98 that was documented.

April 5, 2023 at 10:02 pm #274842You could replace the capacitor with an ignition condenser as long as the microfarad value is the same. Might have to go through the various manufacturer condenser listings in the Mercotronic manual to find one that is .15 uF value and figure out a way to mount it where the original capacitor is or you could also mount it where the contact set is as long as the lead is connected to either the black or yellow wire and the case of the condenser connected to the other wire looking at the pictures you posted. Just a suggestion if you happen to have one on hand that is 0.15 uF value. Then you could just cut one of the leads on the original condenser and bend and tape one of the cut leads and just leave the old condenser where it is for a reference of the correct value in the future.

I would suggest purchasing a condenser from a reputable electronics component supplier rather than off of ebay – just my personal preference as you do not know whether the ones on ebay are ones that a manufacturer or supplier dumped because they were out of spec or?? and as a result the quality may or may not be what you desire for use in a test tool.

Here are a couple of links to a capacitor that should work to replace the one on the Mercotronic and these are only suggestions – you may have an electronics store or supplier close to you that can also supply a similar capacitor. The other thing to keep in mind is that replacing the capacitor may not fix the problem of the low meter reading. Having said that if the capacitor is original it would be wise to replace it from an age point of view the same as if a customer had an engine the same age as your Merctoronic and still had the original condenser you would probably recommend replacing the condenser because of the age of it as good preventive maintenance.

Don’t know if your still hanging around but

I ordered this Mosuer. Seem small to me

but as I don’t know anything, I could have

ordered the wrong thing and I can only relate

to this visual. Need some guidance.

Tubs

A "Boathouse Repair" is one that done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.