Home › Forum › Ask A Member › Mercury K1? Or maybe not?

- This topic has 29 replies, 7 voices, and was last updated 5 years, 12 months ago by

kirkp.

-

AuthorPosts

-

February 16, 2020 at 10:16 pm #195110

Kirk, you are correct. That’s what I was referring to. After re-reading it however I realize Louis was referencing the legs in the many pics you all posted. Also thanks for the additional pics.

While I’m waiting for the flywheel and sheave to arrive, I removed the magneto from my k3 model and installed it on the sea king. Save for the spark advance lever, they appear to be the same. I will have to go through the carb still in order to make it run but I’m one step closer.

I took a green pad to the top of the crank shaft today and there is some rust that didn’t disappear. But most of it did! Do I dare take sand paper or emory cloth to it? The crank case does turn easily and it looks very clean inside.

Scott

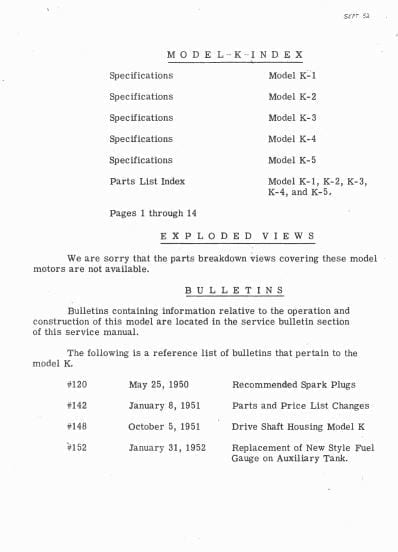

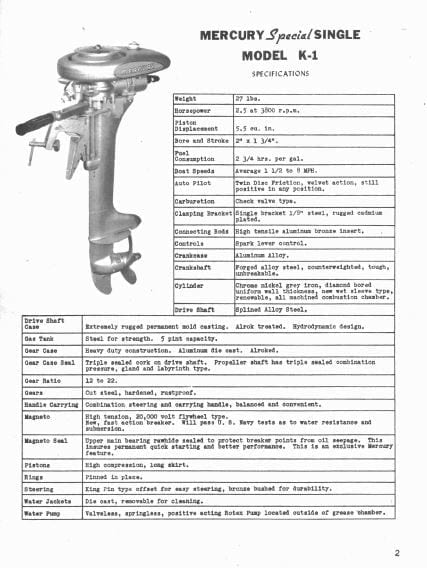

February 17, 2020 at 1:24 am #195114Louis or others will chime in but I believe these early Mercs share components. Don’t know if you already have it but I’m attaching a parts list for the early models.

I don’t think taking some emory cloth to clean up the crank will be a problem as long as you don’t go crazy.

Out of curiosity have you checked the compression? You could probably double nut the crank threads and use a drill to turn it over.

Kirk

February 17, 2020 at 7:08 am #195117Louis or others will chime in but I believe these early Mercs share components. Don’t know if you already have it but I’m attaching a parts list for the early models.

I don’t think taking some emory cloth to clean up the crank will be a problem as long as you don’t go crazy.

Out of curiosity have you checked the compression? You could probably double nut the crank threads and use a drill to turn it over.

Kirk

I haven’t checked compression with a gauge as I rarely do on small pre-1950 motors. Turning it by hand it seemed to have pretty good bounce.

I do have some of the old charts that list parts. Turns out K1/K3 share many parts! I can use the flywheel and mag from my k3 to keep moving forward.

Scott

February 17, 2020 at 7:16 am #195118So the carb is simply a fuel/air mixing valve, correct? What needs to be done to “go through” it? It looks really clean inside. Not really sure how one works. What is the function of the hole-filled chamber on the bottom? I’m assuming that’s where air is sucked in mixed with the fuel being metered by the single needle out front?

-

This reply was modified 6 years ago by

opposedtwin.

February 17, 2020 at 11:31 am #195143Scott, you are correct that it is a simple mixing valve. Yours with all the holes is a new one to me but maybe someone will know what’s going on. Here’s a pic of the valve on my Sea King. Turns out the manual I have is too big to attach. Here’s the first two pages so maybe you can see if it’s different than what you have. If you want me to send it to you, send me an email.

KirkFebruary 17, 2020 at 11:56 am #195152Share and share alike,,well yes and then again no. The single cylinder

models rapidly evolved. Amazingly, almost all improved design parts can be back fitted to earlier design. All are the same, but, all are different one way to put it. Between the two years there are fundamental changes in design. Within the two years there are variations in details.

In tearing down a 1941 KB3 Mercury, I damaged the crankcase, a friend had given me a 1941 Sea King less tank and magneto,,,an easy swap. A friend had a 1946 WD3 with a damaged tower. The Sea King tower was the same and worked just fine. It started, ran and pumped

like a fire engine. BUT, Kiekhaefer postwar Mercury and Wizard models began to have frustrating difference for parts swoppers,

LouisFebruary 17, 2020 at 1:02 pm #195156Actually, that “carb” is a bit more than a simple air/fuel mixing valve. It contains a spring loaded poppet valve that opens and closes with each stroke of the piston. You will note that your motor does not have any reed valves. The poppet performs this function. When the piston moves down in the cylinder, it pressurizes the crankcase, and forces the poppet closed. On the piston’s up stroke, the resulting vacuum in the crankcase lifts the poppet off its seat, allowing air (which mixes with fuel metered by the needle valve) into the crankcase and allowing fuel past the needle valve. You will see that the opening for the needle valve is in the beveled seat for the poppet so that a closed poppet also stops fuel flow. You will be able to hear the poppet clanking on the seat, while the motor is running. These contraptions work surprisingly well.My 1941 Sea King with poppet starts easily and runs smooth. However, you won’t win any races with that motor. You will probably find that you need to adjust the needle valve for best operation as you move from idle to high speed operation, and vice versa, as there is no separate idle circuit.

Kirk’s picture of the bottom of the valve shows a pin and screen. These also perform a function. To start a cold engine, push up momentarily on the pin, which lifts the poppet and allows a bit of fuel to flow past the needle. This fuel will wet the screen, acting to enrich the fuel/air mix and thus prime for cold starting, since there is no choke on these motors, either.

John Van

February 18, 2020 at 2:55 pm #195295John, great description of the operation. Any thoughts on the setup that Scott has?

KirkFebruary 23, 2020 at 4:16 pm #195717I substituted the magneto from my K3 and now (along with the flywheel and sheave Bob supplied) I have a good spark on the sea king.

In the disassembly/assembly I lost track of where the little wave washer goes. Is it underneath or on top of the cam?

I need to clean the tank and get fresh gas to the motor and hopefully it will run.

Scott

February 23, 2020 at 10:41 pm #195768Scott, sent you an email

Kirk -

This reply was modified 6 years ago by

-

AuthorPosts

- You must be logged in to reply to this topic.