Home › Forum › Ask A Member › MERCURY KD-3 WATER PUMP

- This topic has 20 replies, 5 voices, and was last updated 5 years, 1 month ago by

opposedtwin.

opposedtwin.

-

AuthorPosts

-

March 2, 2020 at 11:16 pm #196492

Thanks for that! I got the cover removed. It is indeed a sixteen square hole case with the oscillator type water pump. Now having trouble removing the small pin holding the eccentric to the prop shaft. Getting there a little at a time.

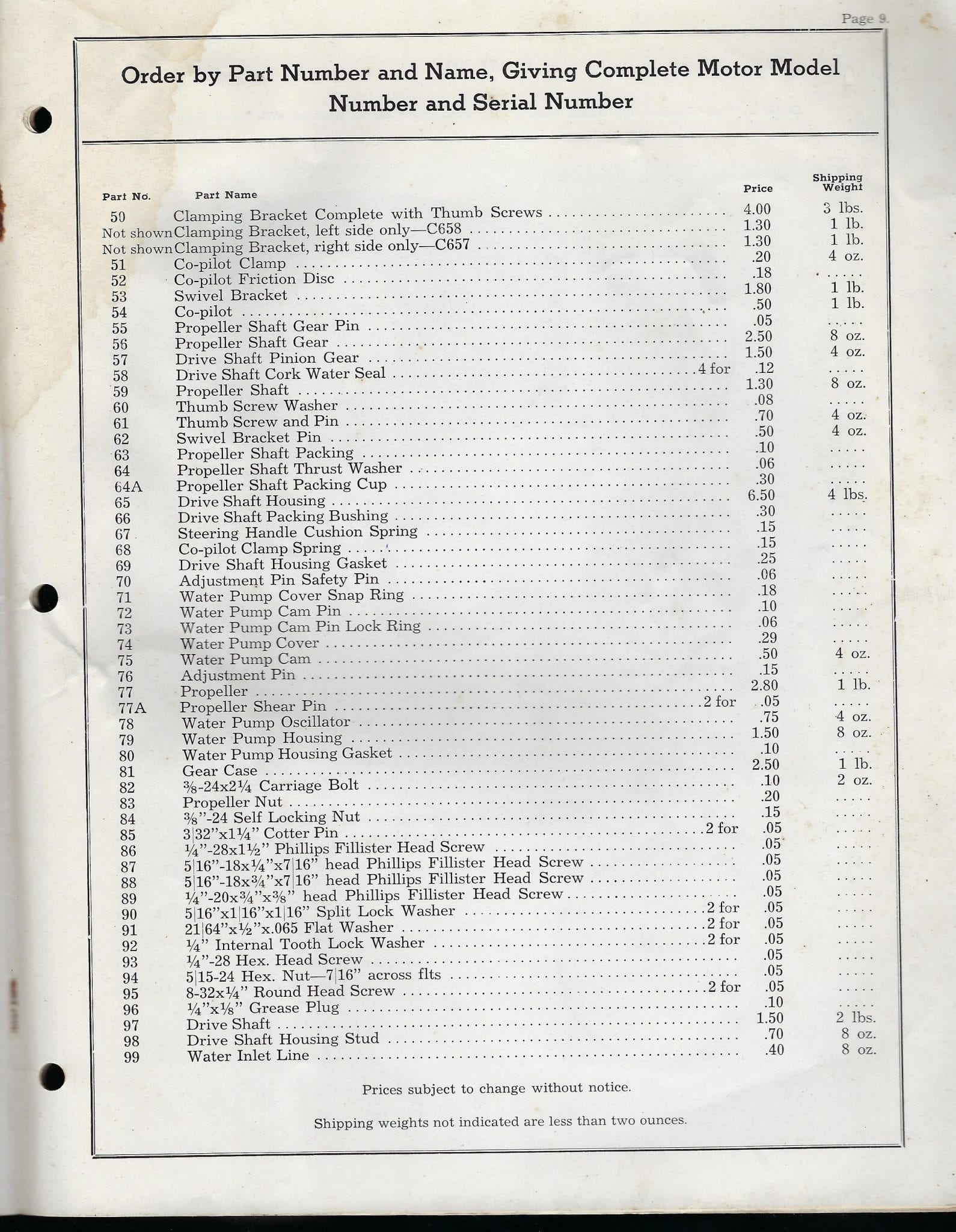

Do you happen to have the text for that plate showing the numbered parts?

ScottMarch 3, 2020 at 6:59 am #196503https://drive.google.com/file/d/0B6wRLMxPeVaiOWIxNDRkZWItOWRjMC00YTJhLTg3YWQtNDU3OWY2ZjRjZjlh/view

On this site under “Technical – Discussion & Videos”

I downloaded Mercury factory training charts and the instructions for the KB-1 Comet which uses the oscillator style pump.Don’t forget to remove the small cir – clip part # 73 from the brass eccentric cam! be careful not to lose??? they go flying!

I tap the drive pins out with a drift pin and make new ones from K & S brass rod available from Hobby Shop or good hardware store.

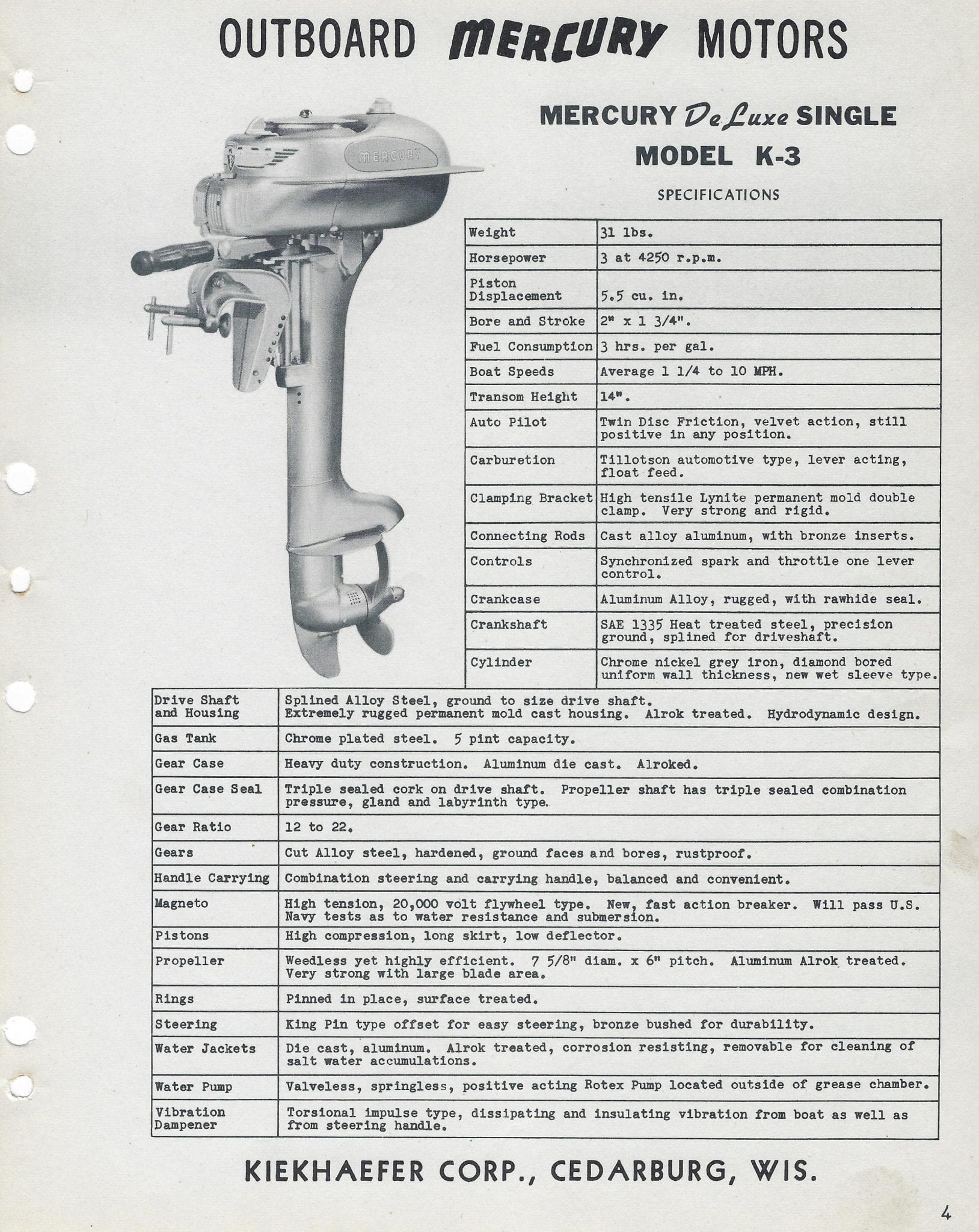

March 3, 2020 at 7:59 pm #196564Thanks Bob! Funny how that info sheet for the K3 describes the water pump as a rotex style when it’s actually an oscillating style!

Do you happen to remember the diameter of the rod you buy at the hobby store to replace the pin?

-

This reply was modified 5 years, 1 month ago by

opposedtwin.

opposedtwin.

March 3, 2020 at 10:58 pm #196591K & S Metals

K & S Engineering3/16 = .1875 “ solid brass rod

K&S Solid Rod 3/16″ D X 12″ L Brass Carded https://www.amazon.com/dp/B00FG1M0MY/ref=cm_sw_r_cp_api_i_4yYxEbNFGPSYG

March 4, 2020 at 11:58 am #196637It seems to me that you are referring to the 2nd type (brass eccentric cam) I believe the K3 would originally have had a 1st type (iron oscillator cam) If so, there is an internal pin in the oscillator cam, To remove this pin, after removing the sheer pin (which drives the propeller) raise the oscillator cam up the prop shaft so that pin aligns with holes in oscillator cam and push pin out. There should be a spring between sheer pin and end of oscillator cam to prevent cam from moving up shaft during operation.

If memory serves the sheep pin is 3/16″ and the oscillator drive pin is

3/16″ .Both pins can be made from 3/16″brass rod using a file and small vise.Getting length right on internal pin is a fit and try, Sheer pinFinding brass rod can be a now you see it and now you don’t proposition. .I bought a 3 foot length of 3/16″ at Lowes and have not

see it there since..I was at Tractor Supply and found one 3/16″

brass rod in the rack…It appears that both stores do not restock when

sold out. Cutting brass rod to exact length can be tricky,,,,best to cut

a little long and file to fit. Sheer pin can be fit to length of slot

inside hub or propeller, same rounding of ends and reduction

of diameter applies.

Servicing a water pump usually involves making replacement pins,

3/16″ brass rod may also be used to make High Steed needle for AJ

series carburetors and an assembly tool to hold rod cap in place with

the needle bearing steel rods

Measure from end or rod to cutting wheel for length, the cut end(s) will be slightly thicker. Chuck in poor man’s lathe (electric or manual drill) to round ends and reduce the raised diameter.Louis

-

This reply was modified 5 years, 1 month ago by

green-thumbs.

-

This reply was modified 5 years, 1 month ago by

green-thumbs.

-

This reply was modified 5 years, 1 month ago by

green-thumbs.

March 4, 2020 at 1:59 pm #196641I learned something new

Today! 1940 oscillator

Cam is different than 1941

Wizard WB-3 that I worked

On last year. The 1940

Cam is definitely steel.

I don’t know to remove

Retention pin that is

Parallel to prop shaft?

Lou, please advise.

Thanks,Bob

March 4, 2020 at 8:00 pm #196673Bob, the retention pin is perpendicular to the prop shaft. It goes through both the eccentric and the prop shaft. Just got mine out just before dinner. I was tapping the “pin” back and forth with a drift set and decided to add some heat. Removed the impeller and after a short heat up period, it started to move considerably faster. The pin must be brass because it’s beat, crooked and junky. Now it’s on to clean up, make a new gasket, lubricate and reassemble!

Keep at it, you’ll get it out.

I believe my eccentric is steel. It’s from my 1940 K3.

Scott

-

This reply was modified 5 years, 1 month ago by

opposedtwin.

opposedtwin.

March 4, 2020 at 8:50 pm #196677I learned a few things too…I have had several of the 1940 16 square

hole pumps apart and never realized the purpose and need for the

spring on prop shaft I also learned not to trust memory…verify by checking part or reference source.

NOW for something to ponder,,,I have been told by a very reliable

source that the brass eccentric cam may be used in place of the iron

or steel eccentric cam. I have not figured out how the grease seal

can be made to function with such a substitution. I suspect some clever reengieering is called for

LouisMarch 5, 2020 at 5:07 pm #196745Louis, when you say “substitution” you mean swapping a brass eccentric for a steel one? Can you post a picture of a brass one? Is it the same design as the steel one?

So there are no lip-type seals in this gear case, correct? Is the bushing around the prop shaft the only thing preventing water from getting into the gears?

Scott

March 5, 2020 at 7:52 pm #19675916 square hole water pump casting has string packing inside base of

iron oscillator cam I believe original to 1940 models7 slit water pump has a thin wall cup with the packing inside, this fits over a lip in casting I believe original to 1941 models and some early postwar models

3 slit water pump (common to most postwar models) has a metal

case lip type seal pressed into casting.

ANY pump assembly will work with any model or year so substitutions

can and were made, Kiekhaefer offered a kit to convert to the

3 slit vane type pump. Kiekhaefer sometimes used old stock partsPhotos show a 7 slit water pump, brass oscillator cam, end in view of

oscillator cam with copper packing cup inside and a view of pump casting showing copper packing cup in place

The groove around the brass oscillator cam is so a short pin can be

held in place by a spring in groove…used when a sheer pin is used

to drive propeller. When clutch is used the spring and short pin are

not used, Instead a longer pin engages the front plate of the clutch

and the rear plate engages the propeller,The iron and brass oscillator cams are different designs, BUT, the

prop shafts are the same on ALL versions from K1 to KE3 and

Wizards from WA2 to WG4 as well as both Sea Kings. Kiekhaefer

planned ahead for both rotax style pump and the clutch. All that

is needed to convert from oscillator type pump to a rotax vane

type pump is 1) 3 slit water pump housing 2) impeller drive hub

3) vane type impeller The rest can be transferred from the oscillator

type pump. The 3 types of water pump are completely different

but share some parts and are interchangeable as asemblies.

A design philosophy that was good for manufacturer, dealer

and customer.-

This reply was modified 5 years, 1 month ago by

green-thumbs.

-

This reply was modified 5 years, 1 month ago by

green-thumbs.

-

This reply was modified 5 years, 1 month ago by

green-thumbs.

-

This reply was modified 5 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.