Home › Forum › Ask A Member › Mercury KD4

- This topic has 139 replies, 16 voices, and was last updated 4 years, 7 months ago by

Boonie.

-

AuthorPosts

-

April 12, 2021 at 6:07 pm #236233

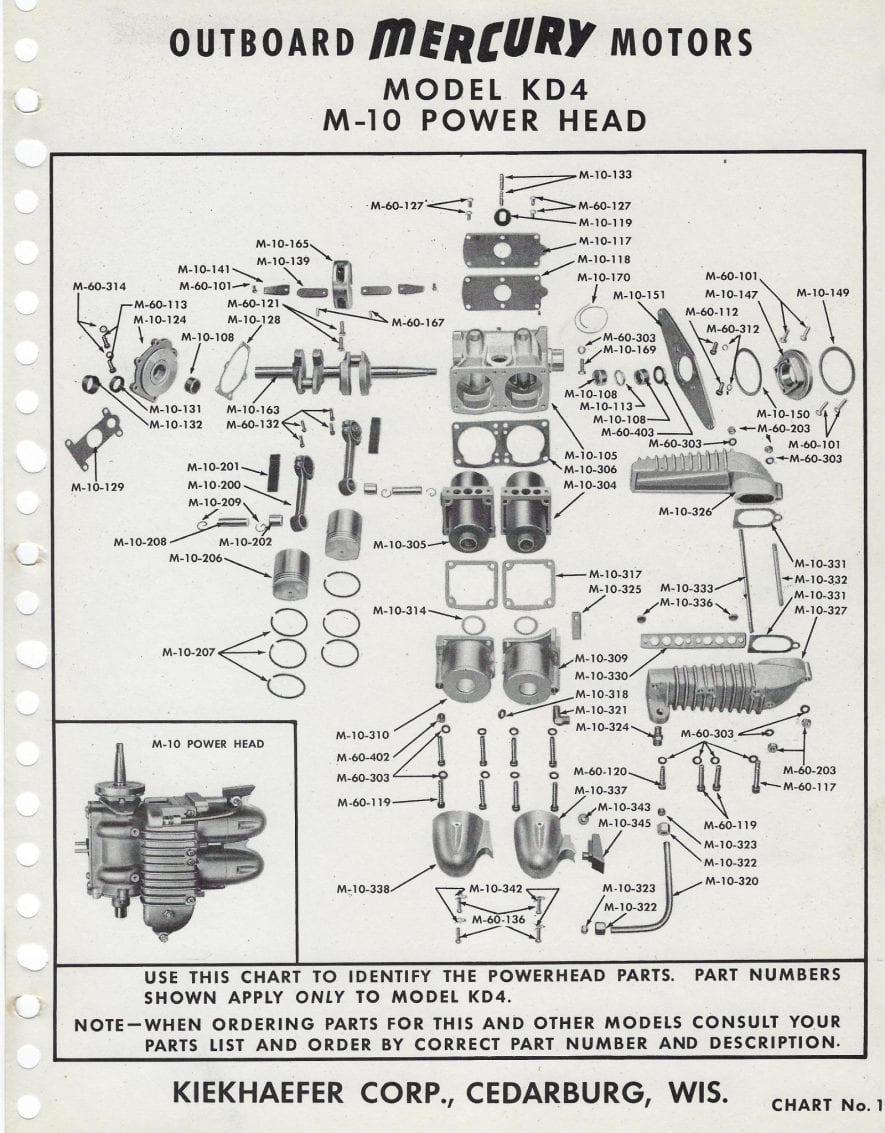

Removing and installing crankshaft/reed block is not difficult if you

have a press or can fabricate a substitute. There are a few things to

keep in mind to do it right. I will dig up photos that will explain process

Bear in mind that to get to point where crankshaft can be removed involves a complete disassembly of powerhead. Upper and lower seal

can be changed without taking powerhed to pieces. Most of the motors

I have came as rusted, busted, or stuck or all 3 so full rebuild was a given. If you like wrenching that is not a problem,

Louis

Pressing crankshaft/reed block in or out of crankcase involves a lot of force applied to crankshaft. To avoid springing the crankshaft install nut and bolt jacks between cheeks of crank throws. I use 1/4×20 bolt

and nut jacks turned snug ,but, not to tight.Sharp eyes will notice crankshaft is from KE4/Mark 7. which has a thinner reed block and 4 reed petals,

-

This reply was modified 4 years, 8 months ago by

green-thumbs.

-

This reply was modified 4 years, 8 months ago by

green-thumbs.

April 12, 2021 at 6:55 pm #236241Thanks Louis. Is this procedure necessary to replace the crank seal?

April 12, 2021 at 8:04 pm #236244NO !

April 12, 2021 at 8:15 pm #236246NO !

Dave,

How do you remove that upper crank seal without removing the shaft?

Does mercury have a special tool for this procedure? I have a seal remover for OMC upper crank seals and it works very well.Scott

April 12, 2021 at 8:59 pm #236249April 12, 2021 at 9:10 pm #236255Yes it does. But I can’t see going thru all of that just to change the upper crank seal!

April 13, 2021 at 10:16 am #236285So I can remove the seal with crank still in the engine case? Just try to pry it out?

April 13, 2021 at 12:29 pm #236299Upper seal can be removed by drilling 2 small holes on opposite sides of the seal, screwing 2 sheet metal screws and prying the seal out, If screws pull out drill 2 more holes and repeat,

Mercury part # for seal is 26-21642

C/R seal 7415 will work

Be sure to lube seal and crankshaft when installing new seal to avoid

damage to seal lip.’It isa good practice to have 7/16″x20 fine thread nut on

crankshaft when working on powerhead to prevent damaged thread.

Before using a nut for this purpose, run a tap thru the nut to be sure

the thread us good, As a part of preparing a powerhed for assembly

it is an excellent practice to run die over all threads and a tap thru

all nuts and threaded holes. Picky Picky, but very often needed,

Louis-

This reply was modified 4 years, 8 months ago by

green-thumbs.

April 13, 2021 at 12:43 pm #236303Thanks Louis. Ordered new rings from Poole yesterday. When they arrive the assembly will begin.

April 13, 2021 at 6:43 pm #236323A bit more about removing and installing crankshHaft/reed block assembly

1) Nut and bolt jacks are installed thru openings on either side of carburetor opeing. Cover plate has to be removed

2) Bolt in side of crankcase screws in to reed block. Remove before pressing and replace after crankshaft is installed.

3) When replacing reed block on crankshaft the screw hole and carburetor passage have to line up,,,

4) Small hole in reed block is key to aligning reed block so that

thread in reed block and bolt hole in crankcase are spot on.-

This reply was modified 4 years, 8 months ago by

green-thumbs.

-

This reply was modified 4 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.