Home › Forum › Ask A Member › MERCURY MARK 55 LOWER CRANKSHAFT SEAL

- This topic has 15 replies, 6 voices, and was last updated 4 years, 6 months ago by

jrm80.

-

AuthorPosts

-

October 5, 2019 at 7:39 pm #184684

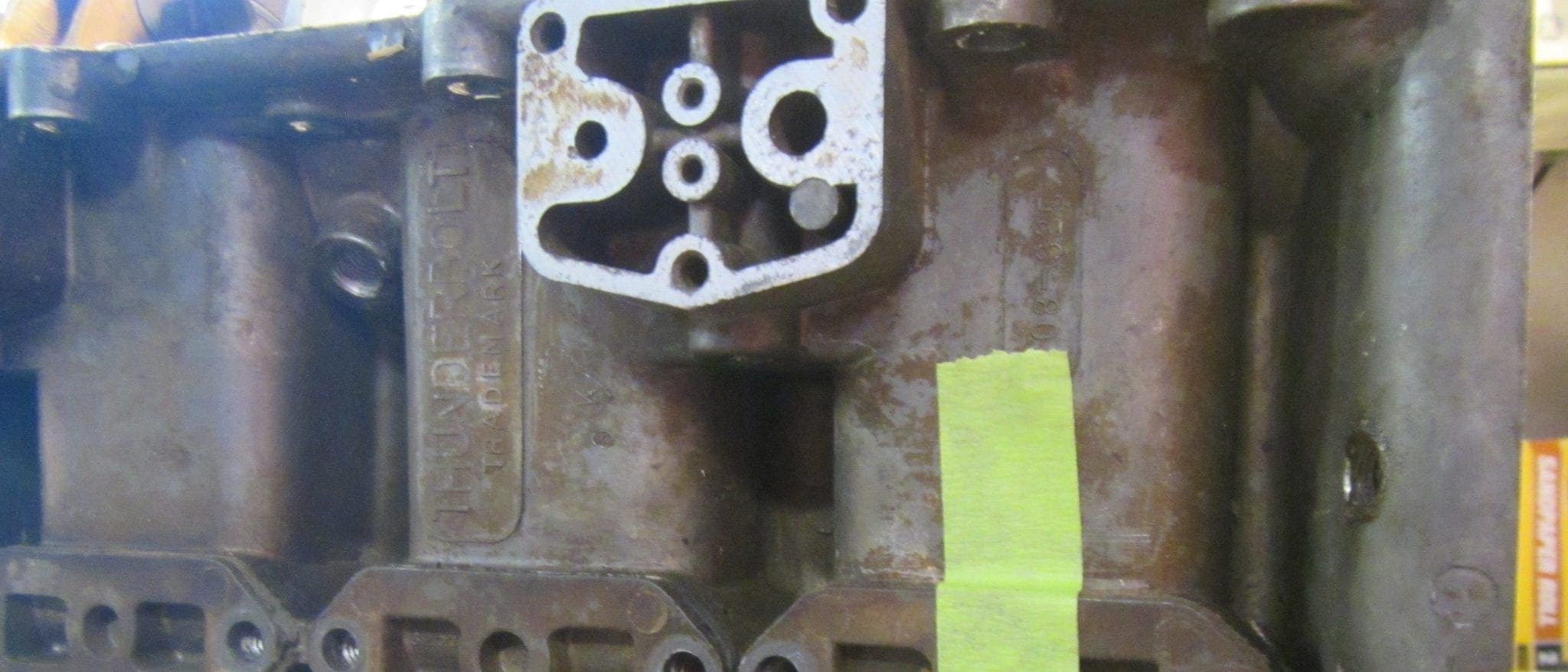

I HAVE A 1956 (I THINK) MARK 55 THAT I AM RESTORING AND IN THE PROCESS RESEALING THROUGHOUT. I FIND THAT THE LOWER CRANKSHAFT SEAL HAS A HOLE IN THE CASE THAT THE UPPER SEAL DOES NOT, AND I JUST DON’T UNDERSTAND WHY THERE IS HOLE IN THE SEAL. SEEMS TO ME THAT PUTTING A HOLE IN THE SEAL DEFEATS THE WHOLE PURPOSE OF THE SEAL, BUT I’M JUST A DUMB COUNTRY BOY THAT MAYBE SHOULDN’T BE WORKING ON THIS THING TO BEGIN WITH. THE HOLE IS DESCRIBES AS A WEEP HOLE OR DRAIN HOLE DEPENDING ON WHO YOU ASK. CAN SOMEONE PLEASE EXPLAIN TO ME WHY YOU WOULD TAKE A PERFECTLY GOOD SEAL AND DRILL A HOLE IN IT? IF IT HELPS, THE UPPER SEAL IS PART # 26-29476 AND THE LOWER SEAL IS PART #26-29477.

THANKS FOR ANY HELP ANYONE CAN GIVE ME.

JIM MCCARTHY

-

This topic was modified 4 years, 6 months ago by

jrm80.

October 5, 2019 at 8:07 pm #184686deleted

-

This reply was modified 4 years, 6 months ago by

frankr.

frankr.

October 5, 2019 at 8:25 pm #184687there are 2 seals in the bottom the lower seal seals the crank from water. the upper seal has the hole to let some oil lube the lower seal .but also seals the crank case.

October 5, 2019 at 9:20 pm #184688When I built mine I asked myself the same question! That bottom seal is also more money. I bought a seal with no hole in it, installed it, and the motor runs incredibly well! Back in those days the engineers thought nothing of dumping gunk in the drink! More crankcase pressure won’t hurt. Do what you want but ours runs fine!

dale

-

This reply was modified 4 years, 6 months ago by

labrador-guy.

labrador-guy.

-

This reply was modified 4 years, 6 months ago by

labrador-guy.

labrador-guy.

October 6, 2019 at 12:30 am #184696like I said IF you don’t use the seal with the hole the lower of the 2 seals will burn.. no lube . then you will be using 1 seal. on later motors the puddle between the seals is sent thru the external hoses to lube the top bearing and center main.. just a side note.

Bolt that nice Mark 55 ON I have seen them come off.October 6, 2019 at 12:36 pm #184717Dave you got me in a near panic!!! So I had to get out my old parts and the two motors that I have had apart have no room for two seals. The line on the outside of the block goes from the center reed and dumps into the exhaust. There is only one drilling in the lower bearing housing and excess fuel/oil that gets through the bearing goes back into the crankcase. Maybe newer motors are different but this 1956 4cylinder has only one seal!

whew dale

October 6, 2019 at 6:38 pm #184747yes as I said later motors.

October 6, 2019 at 6:42 pm #184748THANK YOU FOR THE REPLIES. LABRADOR IS CORRECT IN THAT THERE IS ONLY ONE SEAL IN THIS ENGINE AND NO ROOM FOR A SECOND SEAL. THE NEWER MERCURY 500 WHICH FOLLOWED THE MARK ENGINES SHOWS TWO SEALS, BUT THAT IS NOT WHAT I’M DEALING WITH. MY PRIMARY REASON FOR ASKING THE QUESTION THAT I DON’T UNDERSTAND HOW A TWO CYCLE ENGINE THAT RELIES ON CRANKCASE PRESSURE TO RUN CAN HAVE A BUILT IN LEAK LIKE THIS AND BE EXPECTED TO RUN PROPERLY. IT RATTLES MY ENTIRE CONCEPT OF HOW A TWO CYCLE ENGINE IS SUPPOSED TO RUN. BE THAT AS IT MAY, THE MERCURY ENGINEERS DECIDED THIS SEAL SHOULD HAVE A HOLE IN IT AND I’M JUST TRYING TO FIGURE OUT WHY.

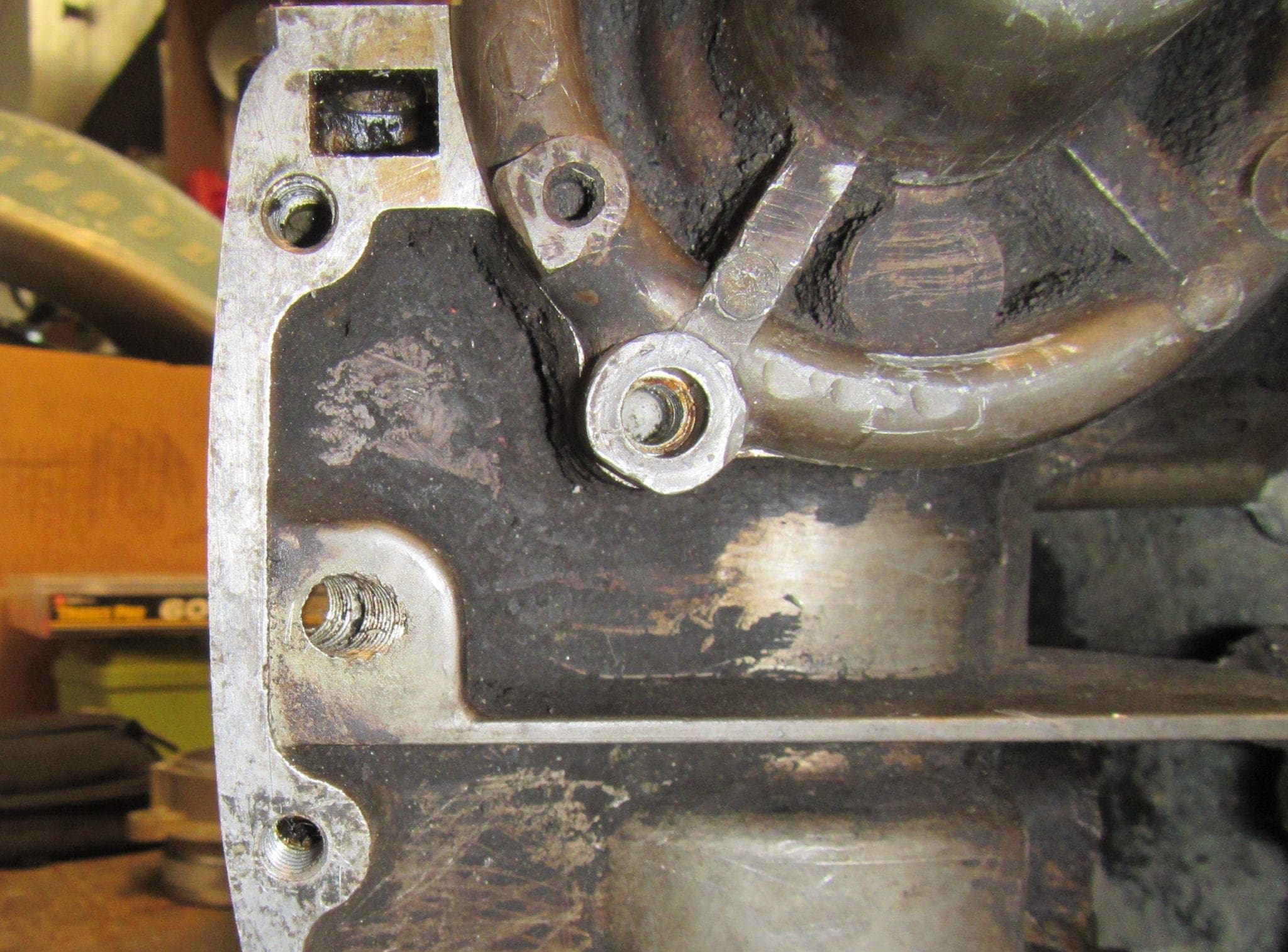

THEN THERE’S THE THE COST QUESTION. THE UPPER SEAL I CAN GET FOR ABOUT 7.00, BUT THE LOWER SEAL ALTHOUGH NLA ARE AVAILABLE FOR ABOUT 30.00 OR MORE. FOR THE DIFFERENCE, I THINK I CAN MANAGE TO DRILL A 1/16 HOLE INTO AN UPPER SEAL AND MAKE IT INTO A LOWER SEAL. ALTERNATIVELY, I COULD JUST PUT AN UPPER SEAL IN THE LOWER END CAP AS LABRADOR DID AND BE DONE WITH IT.

ANYHOW, THANK YOU FOR THE REPLIES. MAYBE I’LL JUST FLIP A COIN AND LET A DIME DO MY THINKING.

October 7, 2019 at 5:30 am #184772Hi Jim,

According to even our oldest Mark 55 paper parts manual (my family was a Mercury dealership when the Mark 55 was introduced for the 1955 year model, and we sold them when new), both the single upper (crankshaft) oil seal and production with a single lower (crankshaft) oil seal do utilize the same part number oil seal. Said another way, there should not be a bleed hole in the oil seal frame. As to the oil seals, we prefer to utilize a Viton lip material oil seal (we sell these for 7.39 each) to have improved life against ethanol blended gasoline, especially so with a single (lower) oil seal version. Buna-N would be the original and currently available oil seal lip material for factory and most aftermarket sources. Yes, one can carefully drill the correct diameter hole in the oil seal frame to create the factory oil seal with the small hole(s) for later models with two lower (crankshaft) oil seals (where the oil seal closest to cylinder #4 has the small hole(s), and the oil seal furthest from cylinder #4 does not have a hole(s)).Regards,

Joe

(770) 597-5992October 7, 2019 at 6:02 am #184774Just to address the OPs original question directly, fuel and oil naturally puddle in the bottom of a two stroke crank case, especially at idle. Getting rid of that puddle can improve idle quality on some engines. This is what Frank R was getting at in his original post. Different manufacturers and different engine models do this in different ways. I don’t do much with Mark 55s but I know Mark 20s had a lower seal with a factory-drilled hole, to get rid of this puddle. ( I have no doubt that Joe Poole is right about the Mark 55 not having one original seal.) Think of it as a controlled leak, that’s all. It should be a tiny hole, way smaller than found in your standard drill set. #53 comes to mind but I forget. It’s small size makes it somewhat insignificant in the overall run quality but will still allow the puddle to be blown out by positive crank case pressure. Some of the seal cases can be tough to drill, too. I remember doing it once, and it took two drill bits to drill one hole.

Long live American manufacturing!

-

This topic was modified 4 years, 6 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.