Home › Forum › Ask A Member › Mid 50’s OMC head gasket sealer?

- This topic has 12 replies, 7 voices, and was last updated 4 years, 3 months ago by

garry-in-michigan.

garry-in-michigan.

-

AuthorPosts

-

January 16, 2020 at 10:10 am #192197

Should the head gaskets (new ones) on the mid 50’s OMC motors (5.5 – 7.5 – 10hp) be used with any type of sealer? Seems to me that I have seen some pros & cons but couldn’t find anything in the search box. If they should require sealer, what kind?

January 16, 2020 at 10:16 am #192199following

January 16, 2020 at 10:40 am #192200I have never put sealer I believe gaskets come with a finish that seals the gasket after getting hot …..so retorque to specs after a few hours

just make certain the cyl head is flat by testing with a straight edge if not resurface by doing figure 8’s on a dead flat surface with 150 grit paper till all the surface is shiny

clean the cyl head of any grit and reinstall

Joining AOMCI has priviledges 🙂

January 16, 2020 at 10:42 am #192201see specs

Joining AOMCI has priviledges 🙂

January 16, 2020 at 10:51 am #192203I have seen some come with a sticky substance on them. But others that appear to be dry as a bone. I have ensured a flat surface by doing the ” figure 8″ with 150 wet on a glass surface.

My intuition says install it dry but I want to make sure I’m doing it correctly. I know the 10hp head gaskets have the copper ring but the smaller hp engines don’t.

I even have a manual that shows lathering on the silver anti-seize compound on the head gaskets.January 16, 2020 at 11:19 am #192204I have seen some come with a sticky substance on them. But others that appear to be dry as a bone. I have ensured a flat surface by doing the ” figure 8″ with 150 wet on a glass surface.

My intuition says install it dry but I want to make sure I’m doing it correctly. I know the 10hp head gaskets have the copper ring but the smaller hp engines don’t.

I even have a manual that shows lathering on the silver anti-seize compound on the head gaskets.You bring up a good point. The copper ring seals the cylinders, using sealer to seal up a poor/corroded/eroded fit in this area has little chance of working out. The sealer is used to help prevent external water leaks. I always use a bit of the OMC/merc gasket sealer when installing new head gaskets, regardless of head gasket style. The pre coated gaskets don’t require any sealer, but using a bit isn’t going to hurt. And yes, I apply the sealer to the inside cylinder edge of the gaskets also, even though it won’t seal up imperfections in this area.

January 16, 2020 at 11:24 am #192205More questions. On page 3-41 of my Seloc 1956 – 1970 Johnson/Evinrude Outboard Tune-Up and Repair Manual for 1.5hp thru 40hp, it states “NEVER use automotive type gasket sealer. The chemicals in the sealer will cause electrolyitic action and eat the aluminum faster than you can get to the bank for money to buy a new cylinder block.” So, does that rule out Permatex Aviation Form-A-Gasket and/or Permatex Indian Head Gasket shellac?

Is that to say that one should never use these products on aluminum i.e., head bolts, exhaust cover bolts, lower housing bolts, etc.?January 16, 2020 at 11:57 am #192207Well, the manual is correct. Some sealers have chemicals, or perhaps copper, that will react with the aluminum and promote corrosion. I am not going to make a blanket statement on what sealers can/can not be used, because I am not a chemist. But, I would certainly read the directions on the sealer you wish to use, hopefully the directions would caution against using on aluminum parts if this is an issue.

January 16, 2020 at 1:29 pm #192213Oh boy, another gasket sealer question. Almost as much fun as oil and Ethanol questions. Let me say one thing first. Evolution happens.

For years, OMC put most gaskets in dry. But that was before OMC invented their Gasket Sealer product. Actually they borrowed Mercury’s Perfect Seal #4. Anyhoo, those copper fire rings were state of the art back when. But I am here to testify they caused electrolysis in salt water. My own personal 1958 Super Sea Horse 35 died after only 4 years in salt water due to the aluminum eaten away at the cylinder/head gasket area. I bought that motor new and it had never been overheated, nor had the head been removed. Eventually, OMC smartened up and started making the fire rings from aluminum, but not all models at the same time

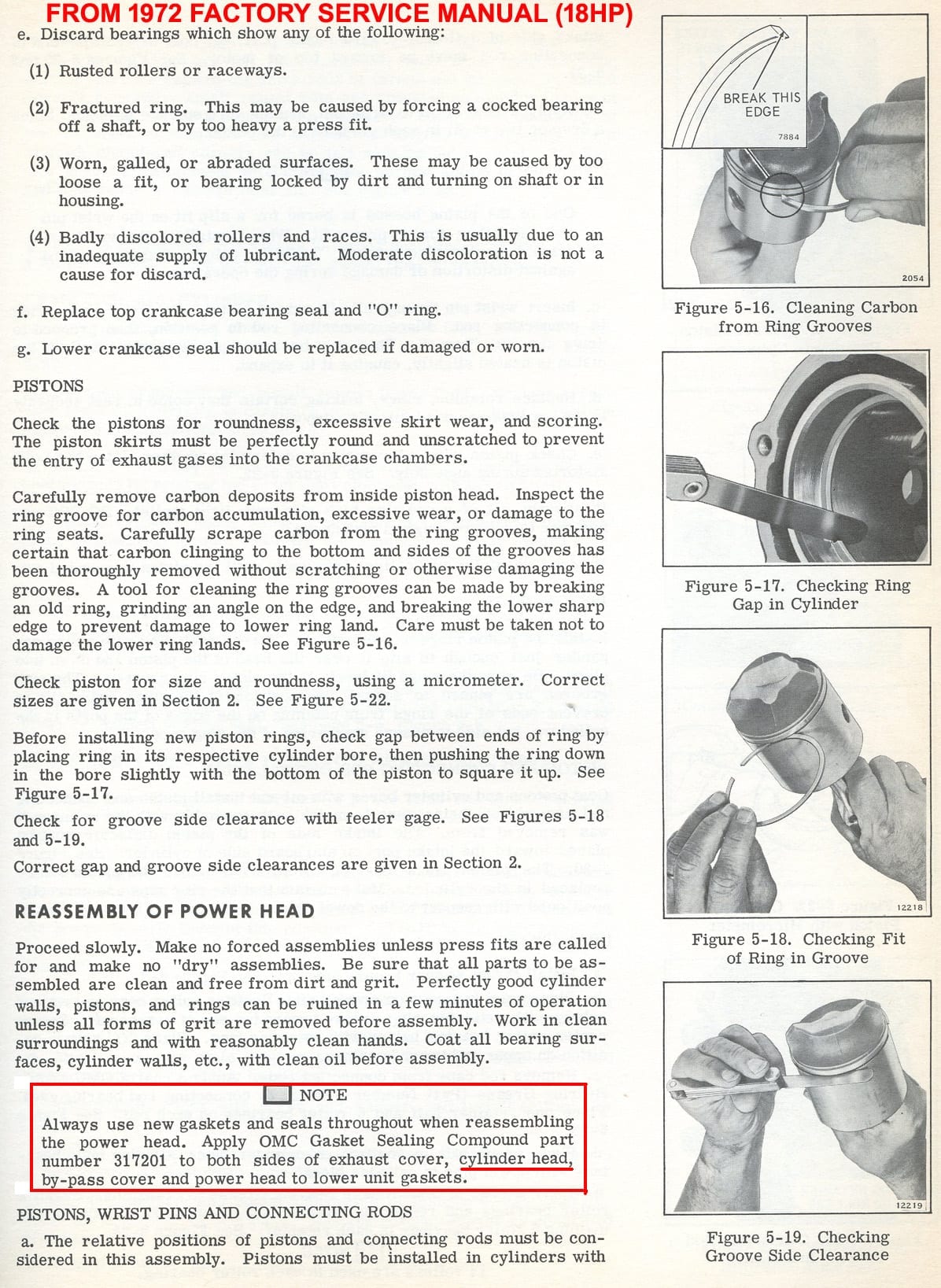

Back to the sealer question. As I mentioned, OMC put them in dry and didn’t even mention the subject in their service manuals. However, posted below, is a page from 1972-18hp Evinrude manual. It clearly says to use OMC Gasket Sealer on the head gasket. Now we all know the 1972-22 cubic inch 18hp motors weren’t that much different than the 1957-18’s So why the difference? Evolution. Or maybe they saw too many motors like my 1958 SSH.

Also, along about that time, OMC came out with gaskets made from a different material and also with aluminum fire rings. They were first used on big motors, such as the V-4’s, and were a direct replacement for previous gaskets Those new gaskets were factory coated with a sealer and were plainly marked DO NOT USE SEALER. They also issued a service bulletin on the subject, which I still have if I were to spend an hour looking for it. Evolution.

Let the opinions continue.

January 16, 2020 at 1:39 pm #192217anybody ever have horror stories after NOT using sealer and torquing properly ?

vs horror stories because of sealers ?????????????????

Joining AOMCI has priviledges 🙂

-

AuthorPosts

- You must be logged in to reply to this topic.