Home › Forum › Ask A Member › Need Help and advice . Elgin lower unit

- This topic has 8 replies, 4 voices, and was last updated 3 years, 7 months ago by

duprebrad.

-

AuthorPosts

-

September 11, 2019 at 8:32 am #183050

Greetings. This is from Elgin 7hp. Model 571.58771 Serial 771.1772.

I really need a parts list for this motor now. Turns out there was water in gear lube . Filled with 90 and let it set a few hours and it mostly leaked out.

Where can I fiind seals, etc. and even more importantly how do you determine substitute seals/bearings for these small motors. I have never taken apart seals on lower units so if there are any tips that would certainly be appreciated.

In the pictures below does the washer even go in there somewhere. It just was loose inside. Does washer go over cable and then the brass tube into the housing?

Thanks

Ralph

September 11, 2019 at 11:24 am #183070Do you have a bearing supply house in your town? They usually can match seals by size if you take in the old ones for samples.

You probably won’t ever get it to hold oil. It was designed for grease. Most people use Lubriplate 105 “Motor Assembly Grease” from NAPA.

September 11, 2019 at 11:49 am #183078yeah. I know about the oil. Just did it for a test. Today I pulled off Prop and Hub I guess. I am going to make up a fitting to try a pressure test (8lbs) and find out which seal it is. I did see fishing line (braid) around prop shaft so I suspect that is the area. Not sure about bearing supply but it is a good idea. Thanks

Any idea if Jim Moffett(spelling) is around? Hoping he may have some elgin documentation on this model .

September 11, 2019 at 12:12 pm #183080September 11, 2019 at 7:28 pm #183129Thanks Frank.

That is pretty different from mine. I did not open the case but my Prop shaft had a different spring setup and what looks like a design with a bunch of shims and spacers . Probably designed to be able to hit bottom without damaging gears. My pressure test was half assed but seemed pretty good. I think I will just run it with the grease once I get the lubriplate and at least put the carb back together and see if I can fire it up for first time in 30 years. I got the spark working so hopefully the carb work will be good too.

September 11, 2019 at 7:34 pm #183130forgot to tell you the impeller was still pretty flexible. Got it soaking in soapy water and it is seeming good to go. Gas tank with acetone and BB’s seems to be pretty clean already. I will put an inline filter as well and probably remove the tank screen.

September 12, 2019 at 9:59 am #183165You can use other grease types besides Lubriplate, just not #2 wheel bearing grease. John Deere has Corn Head Grease which is #0, and TSC has Super S Spindle grease which is #00, either should work well.

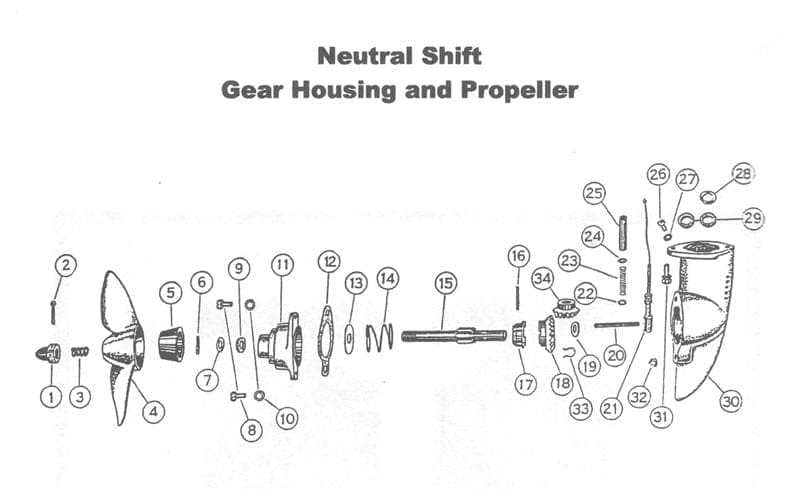

November 24, 2021 at 12:16 pm #250190I have an Elgin 7.5 HP, about a 1957 , model 571-58782 . For the neutral shift, I believe the spring (#23 in photo; 1 3/16th length) sits on top of the plunger like piece. Then there is a washer (#24) on top of the spring , and on top of the washer is a brass tube (#25, 1 9/16 inch length). When I disassembled mine the washer, #24, was missing. I think this is the correct assembly of the parts. Please comment if not accurate. Also what keeps the tube, #25, from sliding up the cable?

-

This reply was modified 3 years, 7 months ago by

duprebrad.

-

This reply was modified 3 years, 7 months ago by

duprebrad.

-

This reply was modified 3 years, 7 months ago by

duprebrad.

-

This reply was modified 3 years, 7 months ago by

duprebrad.

1 user thanked author for this post.

November 24, 2021 at 1:43 pm #250199For the Elgin 7.5 HP, what is the gas/oil ratio? Any recommendations about a less smoky oil?

-

This reply was modified 3 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.