Home › Forum › Ask A Member › Need help diagnosing Evinrude 9.5 problem

- This topic has 43 replies, 16 voices, and was last updated 8 years, 1 month ago by

titantn.

-

AuthorPosts

-

February 9, 2017 at 1:51 am #52677

I have inspected the wires and they look okay, but I’m with you – I need to just go ahead and replace both the coil packs and the plug wires. I will do so and report back.

Any recommendation on where to purchase these items?

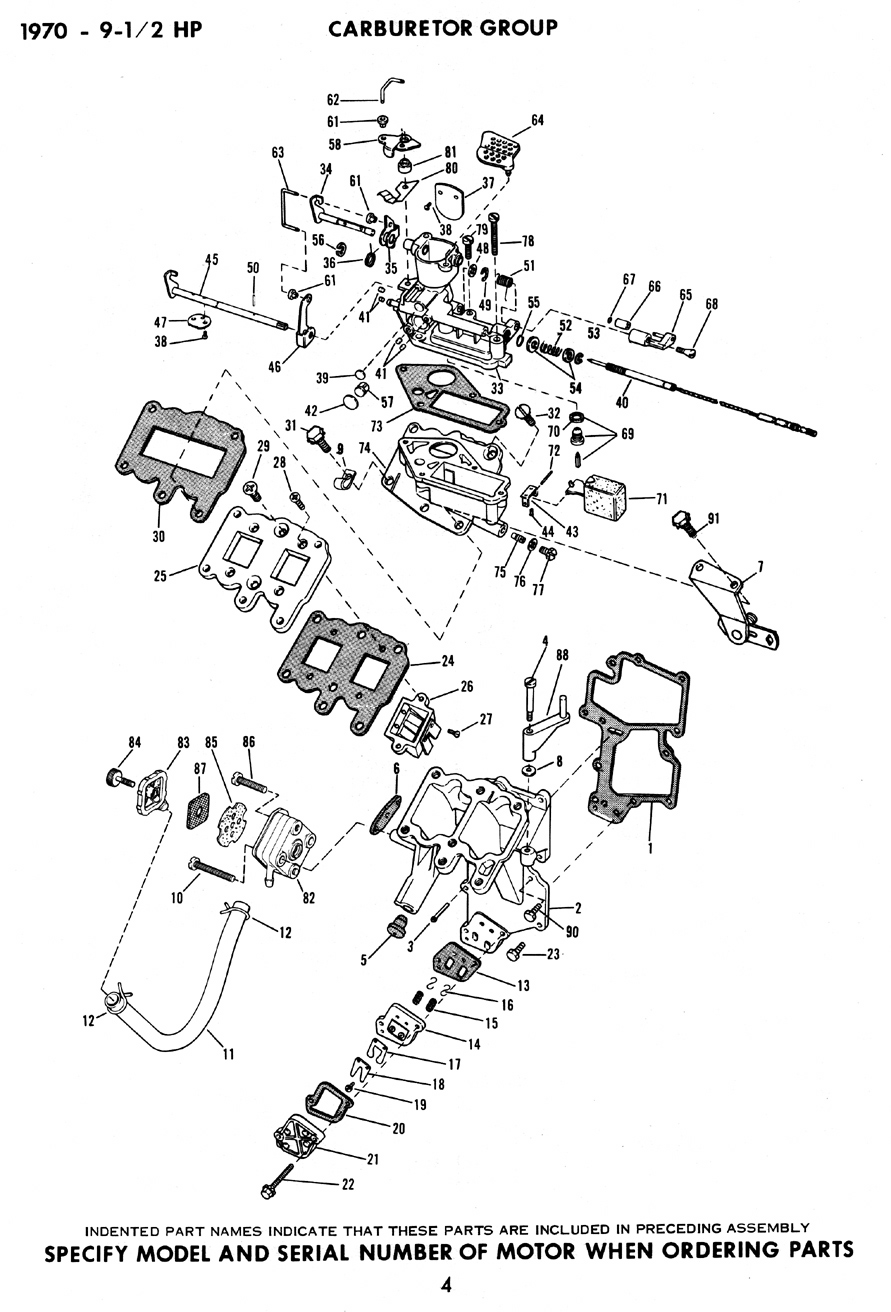

February 9, 2017 at 2:10 am #52679If you pull the carb, make sure that you take off the whole carb. It is a two piece carb, and the lower portion of it has the fixed high speed jet in it. To get it out, you have to move the throttle until the hidden screw appears. Reassembling it, check a parts list to make sure you have the correct packing.

February 9, 2017 at 2:24 am #52681Hope this helps . . . 😕

February 9, 2017 at 3:10 am #52683quote TitanTn:I have inspected the wires and they look okay, but I’m with you – I need to just go ahead and replace both the coil packs and the plug wires. I will do so and report back.

February 9, 2017 at 3:10 am #52683quote TitanTn:I have inspected the wires and they look okay, but I’m with you – I need to just go ahead and replace both the coil packs and the plug wires. I will do so and report back.Any recommendation on where to purchase these items?

Coils are available from your local Evinrude dealer, Marineengine.com along with other online sources, or AOMCI member Jim Judkins to name a few. Jim has an ad in the Free Classifieds section. You can purchase solid copper core spark plug wire in bulk from most auto parts stores or online. Marineengine.com sells complete plug wire assemblies with new clips and boots on them also if you choose to go that route. I buy solid core wires on a 100 foot spool and cut to length and reuse the clips and boots if in good condition.

-BenOldJohnnyRude on YouTube

February 22, 2017 at 3:37 am #53404Okay. I’m reporting back. Not good news. I have replaced the points, condensors, coil packs, plugs, wires, caps, and confirmed the points setting. While I can’t get it to fire at all, I have another problem that may be related. I noticed that the pull cord was hard to pull, and occasionally it would lock the armature plate and the flywheel together. I took the flywheel back off and everything freed up and operated smoothly. Put the flywheel back and and pulled some more with normal resistance – but no starting. Then it happened again. Pull the flywheel again and as you can see by the photo below, the flywheel it hitting the contact point on the coils too much. It’s about to damage my flywheel. Any thoughts? I bought the OEM coil packs from marineengine.com.

February 22, 2017 at 3:48 am #53407February 22, 2017 at 3:53 am #53408The piece under the green coil laminate is what I am talking about. Line your coil up with that and you will be fine.

February 22, 2017 at 3:57 am #53409Some new ( China) replacement coils have laminates that are junk ! They cant be adjusted far enough back to give enough clearance between the flywheel magnets and the heels of the laminates. What I do is carefully knock the new coils of their laminates and swap them on to the original laminates. Use a little epoxy glue to hold them in place. The coils themselves seem to work just fine.

February 22, 2017 at 4:02 am #53410If you don’t have a tool to align the coils, they can be set with a straight edge. The coils sit on little towers, two per coil and the outer edge of the coil must be in line with the machined area on the towers or else they will rub on the flywheel. It’s a pretty tight fit in there so alignment is critical to help get a hot spark. You will also want to clean all of that metal powder out of the magneto before trying to start it.

February 22, 2017 at 4:09 am #53411Check out this link . 😉

viewtopic.php?f=5&t=5865&p=30331&hilit=laminates#p30331

-

AuthorPosts

- You must be logged in to reply to this topic.