Home › Forum › Ask A Member › Need help diagnosing Evinrude 9.5 problem

- This topic has 43 replies, 16 voices, and was last updated 8 years, 1 month ago by

titantn.

-

AuthorPosts

-

February 22, 2017 at 1:03 pm #53418

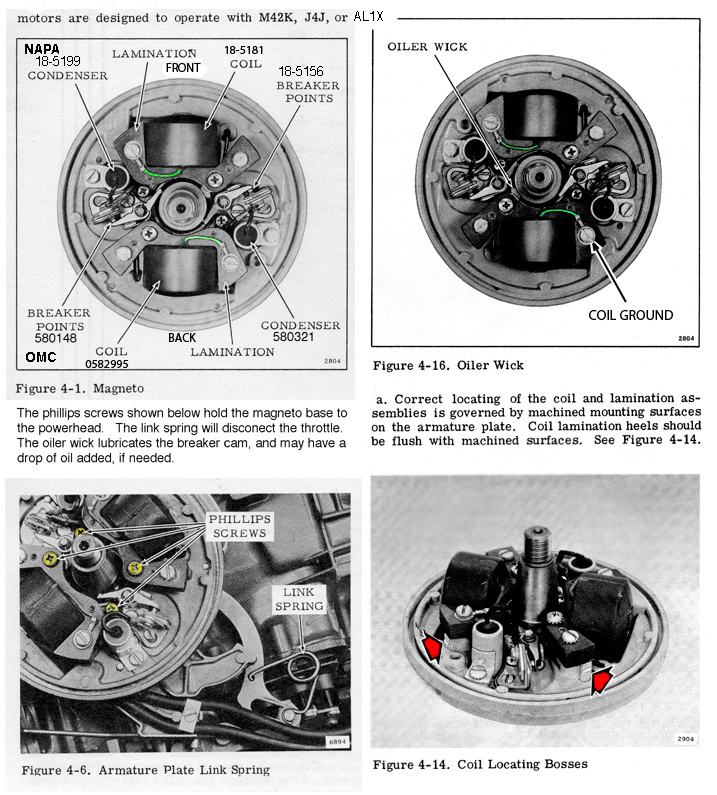

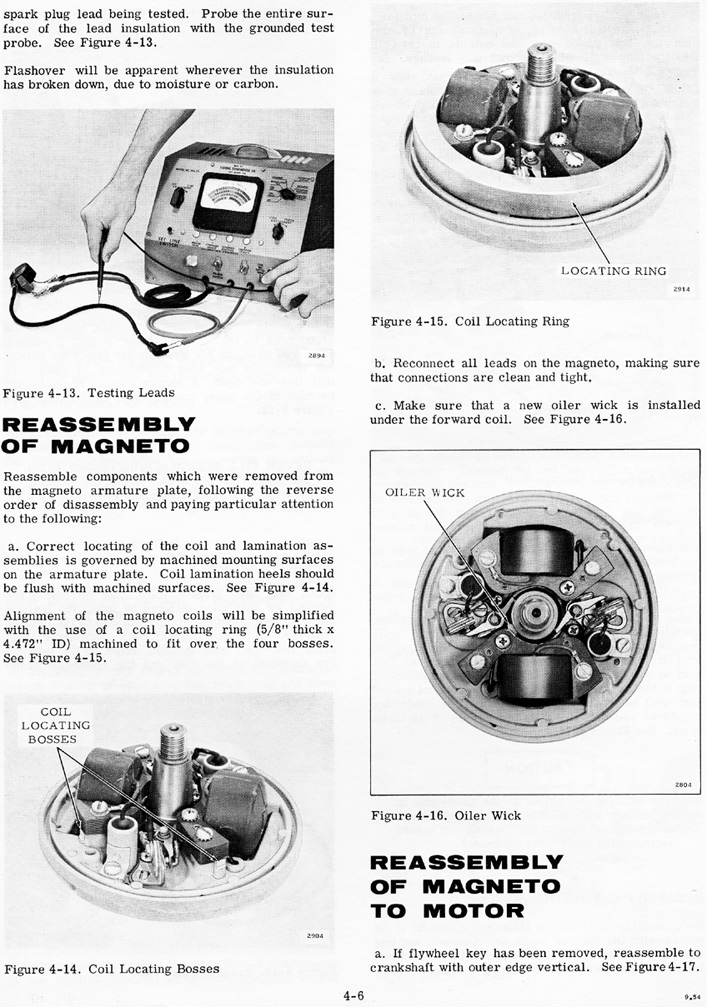

I’ll bet by now, most vendors have sold the remaining Prufex coils and are now carrying the Chinese version. So, the laminates may be rubbing the flywheel despite being set by the locating ring. One other possible problem may be a worn armature [mag] plate. If the center bushing wears out, the mag plate will flop around while the motor is cranked/run and can cause the rubbing problem. Grab the plate with both hands, and while watching the point gap, try moving it back and forth against the crank. Sometimes you can even see the point gap change if you have enough wear. If you need a replacement plate, there are some new old stock parts available from several club members.

February 22, 2017 at 2:07 pm #53421This may be a very simple problem, let me explain. I had a motor miss too like yours just after a tune up too! I metered everything & all is OK? Then I looked at the points again & found some oil on the contact areas. I thought top crankshaft seal but no! No oil coming from there. Next was my feeler gauges. They had a film of oil on them. Cleaned everything with acetone & re-gapped. It fixed the problem & may be yours. Check for oil spray around the top seal using a Q-tip to wipe it down too. Take the magneto apart, inspect & use a meter on each connection as you assemble to be sure. It may not "look" bad but the meter will show a resistance that may be hiding. DO NOT forget your capacitors using the ohmeter battery to look for the small charge made by the meter battery to discharge. An analog meter is better. If no help I would look again at a gasket missed in the carb or dirty jet or passageway.

How about your crankcase halves sealing area? See any bubbles as you turn it over by hand or excess oil around the sealing area?

Sorry, I missed page 2, some data here from me may not apply, sorry, 😳

I can add this. Be sure to use masking tape on the heels of the coils. Install the flywheel without the nut & roll over the flywheel a full turn. Next remove the flywheel & look for rub marks on the coil heels. Good way to check clearances. Remove tape.

Good luck!!February 22, 2017 at 3:35 pm #53427must be some variance on coils because I just installed 2 on my 9.5 9622a with no issues

Joining AOMCI has priviledges 🙂

February 22, 2017 at 4:42 pm #53432A coil locating ring is virtually fool proof, but it can be done without one by careful attention to details. . . 😉

February 22, 2017 at 6:43 pm #53435

February 22, 2017 at 6:43 pm #53435Wow. WOW. You guys are all over this. I can’t wait to get home tonight to work on this. I had no idea about the alignment of the coils as there didn’t really seem to be much wiggle room, but I can see how they would be enough to cause the problem I’m having.

February 23, 2017 at 2:56 am #53452All of this info was a big help. Thank you SO much. It’s running. The stutter is gone and it idles great. Started on the second pull.

But now I have another issue. While it starts and idles great, it doesn’t run up the rpms very far. It doesn’t seem to bog down very much, but just doesn’t want to run very fast. I’m wondering if I’m dealing with a carb issue now. The idle richment screw didn’t seem to do anything at all so that makes me also wonder if something isn’t adjusted properly on the carb.

February 23, 2017 at 4:49 am #53458A lot of people feel the horse power of that model is over rated. In order to keep water out of the powerhead, the exhaust goes up to the top of the cylinder block before it goes down. That restriction really limits the horse power. They won’t do anything in a test tank. . . 🙂

February 23, 2017 at 10:42 am #53460

February 23, 2017 at 10:42 am #53460I have one. A speed demon it is not but they really run smooth.

February 23, 2017 at 1:39 pm #53468quote Garry in Tampa:They won’t do anything in a test tank. . . 🙂Ok, so if I take it to the lake you think it will run more rpms? I’m going to give it a whirl.

February 23, 2017 at 2:03 pm #53469The high speed needle is a non-adjustable jet. It is located just inside of the front of the carb down towards the bottom. There is a bolt head in front of it. You can drain the carb by removing this screw before winter or when you are done with it for awhile. When you cleaned the carb, did you take off this part of the carb?

-

AuthorPosts

- You must be logged in to reply to this topic.