Home › Forum › Ask A Member › Neptune Mighty Mite

- This topic has 8 replies, 6 voices, and was last updated 8 years, 5 months ago by

drifter.

-

AuthorPosts

-

May 5, 2015 at 7:12 pm #1416

I picked up a nice little Mighty Mite and have decided to try a test run prior to going through the carb and magneto.

It has good spark and – although I have not yet checked compression – has good bounce back.Since this is my first Neptune, I do have a couple of questions.

My model is a WC1 s/n H3140 RR. It’s a Georgia motor. Can someone tell from the s/n what model year my motor is?

What is a starting point setting on the main needle valve and the idle adjusting screw?

Is Corn Head grease suitable for the L/U gears?

Thanks for the help,

NickMay 7, 2015 at 1:46 am #15458if it’s a WC1 1961-69 If its a Georgia motor model 500 after 1972 Still trying to decipher serial codes for the WC1 looks like the RR is a mid unit Followed buy the RS

May 7, 2015 at 1:52 am #15460Oh

3/4 turn to start then adjust to run. 1/4 turn on main "Grease" in gear caseMay 7, 2015 at 2:25 am #15462Now what the heck is ‘Corn Head grease’?

May 7, 2015 at 3:34 am #15468quote legendre:Now what the heck is ‘Corn Head grease’?It’s special grease for the gearheads on corn harvesters. An added bonus is it’s perfect for our non shift outboard gearcases!

http://www.greenpartstore.com/John-Deer … 02562.html

May 7, 2015 at 10:01 am #15472Available at your local John Deere dealer. Inexpensive too. It’s quite a thin grease lower viscosity. It’s non-channeling so it will stick to the gears, many greases will not.

http://www.omc-boats.org

http://www.aerocraft-boats.orgAugust 21, 2016 at 12:18 pm #42434Yes, I know. This is an old thread. Just wondering how the corn-head grease worked out. I use corn-head grease in the bottom rollers in two of my bulldozers. Deere used to sell it as "track & roller" grease, but changed it to "corn-head grease" in the late 80s.

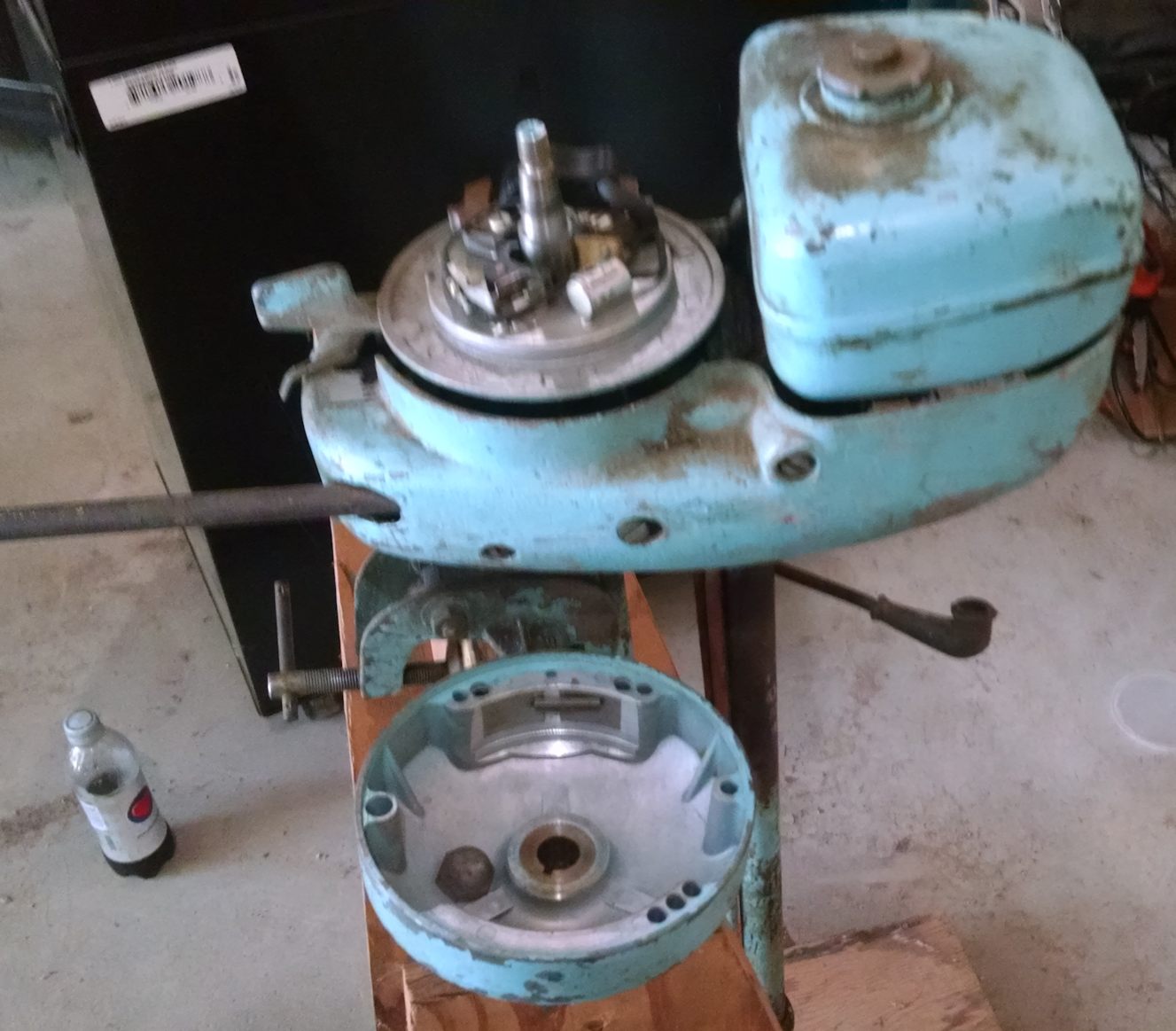

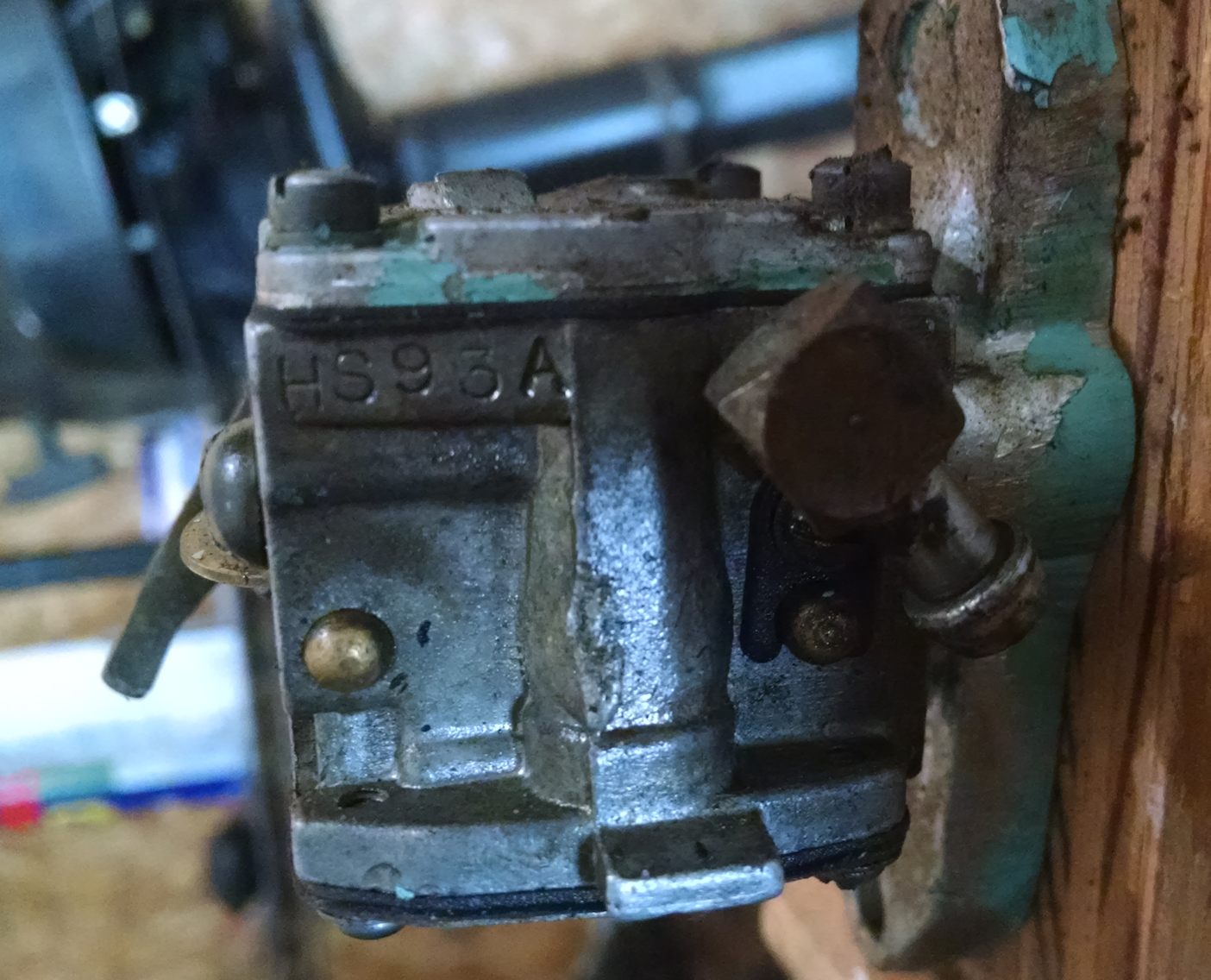

I ask because I just pulled apart a Neptune 500 I got at a yard-sale for $25. Serial # 3464G. No spark and there seemed to a be lot of play when I jiggled the flywheel back and forth. So I pulled it all apart. Points are corroded and capacitor is dead. Play I felt on the flywheel is from loose piston rings. They jiggle in the piston-groove. New points were easy to find since they are in my NAPA small-engine ignition book. Same points used in many Tecumseh and Clinton engines. Carb is a Tillotson and parts for that are very common in many chainsaws. What surprised me is the gear-case. Dry and looked to be full of dirt and sand. I cleaned it up and the gears look fine. Too much play and they skip though. I need to add shims to push one bevel gear closer to the other. I have no repair info on this engine and up to now – had no idea what sort of oil or grease to use. Corn-head grease might make sense. It is made to flow when there is movement and not flow when all parts are still. It is just a 00 grade grease as I recall.

August 21, 2016 at 12:56 pm #42438Here are some photos. The play when I moved the flywheel back and forth had me worried at first. I thought it had a loose rod or wrist-pin. Nope. Just the rings jiggling in the piston-grooves and yet – once expose – I don’t see much wear. As to the ignition – it has a moving breaker-plate that advances as it is throttled-up. So I am not sure if I should just put in new points and condensor – or try an Atom or Nova II module. My Atom is NOT one of the ones made specifically for a rotating breaker plate. Neat little engine and I’d like to use it as a spare "get me home" motor on my 14 foot Glastron.

August 21, 2016 at 2:16 pm #42441My little Neptune runs like a watch. Starts instantly (hot or cold) and really turns up. Corn Head grease is the best for gear cases. If a farmer uses it, then it’s got to be good. It won’t freeze and it won’t melt (within reason of course)

-

AuthorPosts

- You must be logged in to reply to this topic.