Home › Forum › Ask A Member › Newbie Questions Restoring 1957 Johnson 18hp FDE-11

- This topic has 53 replies, 16 voices, and was last updated 5 years, 11 months ago by

bobw.

bobw.

-

AuthorPosts

-

December 7, 2017 at 1:17 am #8809

Hi All,

I’m a newbie to antique outboards and was recommended to this sight by an AOMCI member, Travis.

I recently completed building a Glen L Squirt http://boatbuilders.glen-l.com/squirt-design/nggallery/squirt-design/Squirt-built-by-Jim-Young,-Brighton-MI and I’m powering it with a 1957 Johnson 18hp FDE-11. I bought the motor before I started on the boat, and a friend helped me get it running. It starts easily, runs fine, and looks good on a mahogany runabout. I am in the middle of restoring the motor mechanically and cosmetically, and have a few questions…

I have the motor torn down, and have identified most of the parts/gaskets I need and ordered them from Dan in TN. The motor has 115psi compression in each cylinder, and there is no scoring of the pistons. So, I hope to not have to crack open the crankcase. The coils were replaced by the previous owner, but the plate is covered in oil, so the top seal will be replaced.

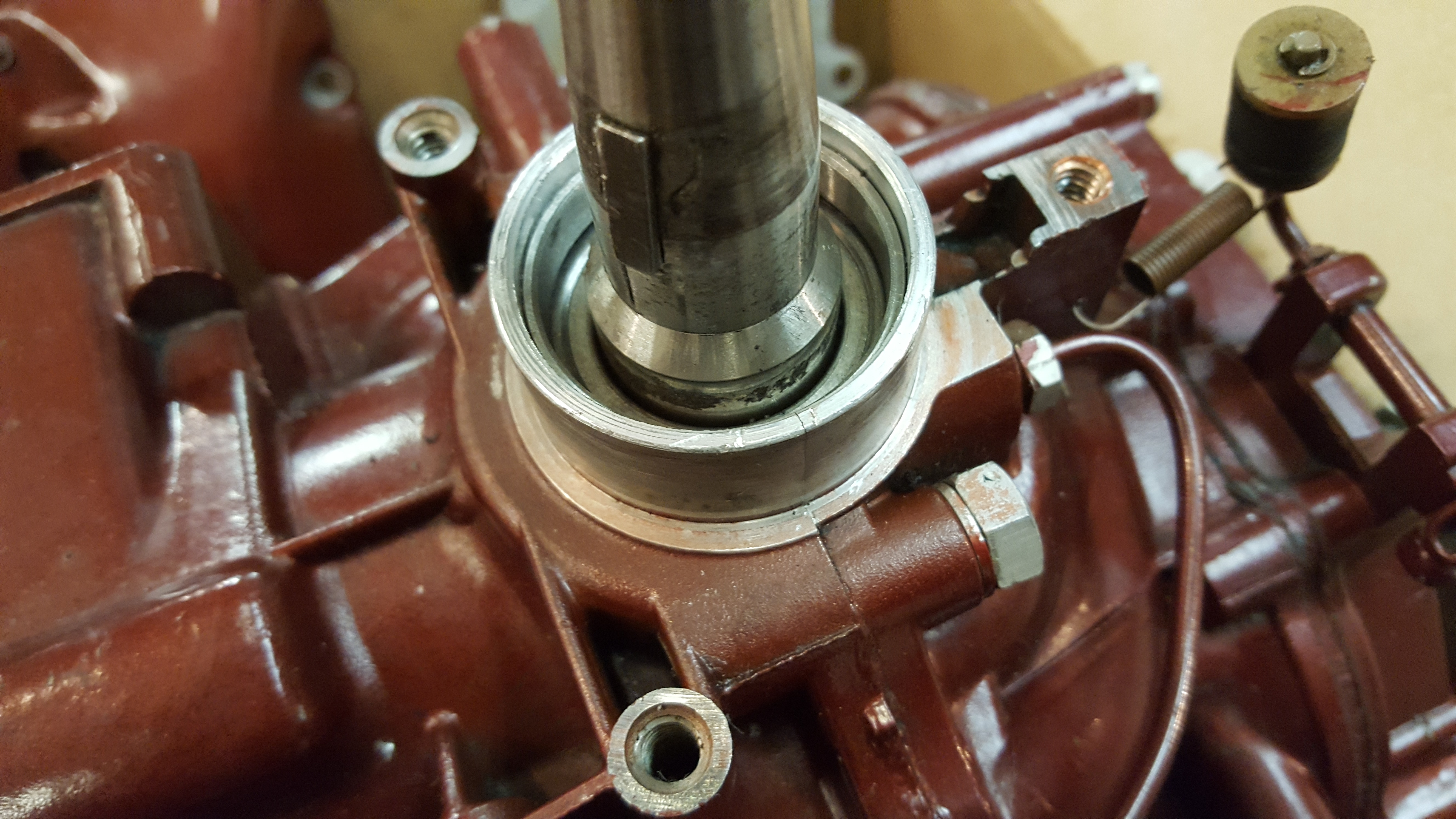

First questions, I removed the top oil seal and noticed some black areas on the crankshaft. I thought this was just the disintegrated seal, but it is pitting of the crankshaft under the seal. Can I get by without replacing the crankshaft, or is there a way to repair it? Will the new seal last if I don’t? I checked the bottom of the crankshaft, and the carbon seal is fine, but the internal quadrant ring will need to be replaced, and there is no sign of rust.

Next when I removed the power head from the lower unit, there is no baffle plate (P/N 0304589). According to the parts diagrams, there should be a plate between 2 identical gaskets. Do I need this plate for this motor? I searched around here and on other OMC motors it looks like this may not be necessary. Is this true for the FDE-11s?

After using the motor a few months this year, the gear case was full of water. So, this will be rebuilt with new seals. The forward brass bearing and drive gear bearing are black with some "corrosion." Is this a concern, should I attempt to remove it?

I think the gear case would be easier to prep and repaint the gear case if it was one piece, so I want to reassemble it prior to media blasting it. If it is assembled without oil (so it doesn’t leak out the water pump while painting) should I grease up the internals to keep them from rusting? If so, with what?

The carb is in good shape, but I have ordered a rebuild kit anyway. Fuel lines have been replaced. Pretty much all gaskets and seal will be replaced. I have access to a paint booth, so I’m looking at NY Marine or EffenA paints. I’m leaning toward NY Marine since they also carry decals, grommets, and I like the idea of single stage paint. Any comments here?

I am looking for the following parts, if anyone out there has them let me know the price:

376837 (Steering Handle, mine is cracked)

0303842 (Thrust Washer at bottom of pivot column)

0304589 (Baffle if it is necessary)

0304070 (1 screw for gear case (1/4-20 x 7/8", with integral washer) was damaged during disassembly)Thanks in advance for any and all help and advice.

December 7, 2017 at 1:28 am #68334Hm-m-m-m-, kind of a judgement call on the pitted crank. I would be more concerned at why is it pitted in the first place? Might be concerned enough to open it up and check the bearing for pitting. That can be fatal.

The baffle plate is supposed to keep water, exhaust, and nasty away from the end of the crankshaft & seal area. Opinions vary as to how effective it is. I’ll let others give theirs.

December 7, 2017 at 1:44 am #68336December 7, 2017 at 2:44 am #68341Thing is, there shouldn’t be any moisture such as that under the seal. So where did it come from and why?

December 7, 2017 at 5:32 am #68343You say it is pitting, but could it be residue from the old seal? I’m with FrankR if it is pitting. You just about got to look & see if the rod bearings have been effected if you think moisture has been present. Any damage to the rod bearings will result in a short life for the motor.

If on the other hand you could remove the residue with a sharp pick tool them you might could clean up the crank & the new seal I sent would be fine. Here is hoping! Let me know when you get the parts.Dan in TN

December 7, 2017 at 4:00 pm #68353When you replace seals in the lower unit, don’t forget the O-Ring on the shift rod – a common place to leak. It often gets overlooked by people doing this for the first few times because you can’t see it. Below is a link (courtesy of Frank) for the replacement procedure, and this o-ring comes with seal kits:

Davehttp://www.franksoutboardtools.com/shift-rod-bushing-remover.html

December 7, 2017 at 4:57 pm #68357JimmyY, sent you a PM regarding parts for your unit. Ed

December 7, 2017 at 5:11 pm #68359Well, I guess I would begin by looking at the old seal, is the seal lip chewed up? You may have chewed it up trying to remove it I guess, so this might not be an accurate evaluation. Like all have said, I would definitely look closer at those black spots on the crank, perhaps with a sharp pick to see if the black stuff is just a residue from the old seal. You are in trouble if those are actually pitted areas, not just spots.

Adding the baffle is a judgement call, probably not an issue if used in fresh water.

I would not worry about the black discoloration on the forward gear/bushing, not uncommon after water intrusion. I would resuse the pieces if the bushing still fits tight and rotates easily on the gear.

I would probably just reinstall the driveshaft/propshaft/bushing seal into the gearcase, then reassemble prior to media blasting to ensure none of the stuff gets inside the gearcase. Be sure to remove the SS water inlet cover and clean that passage thoroughly after media blasting though, left over sand/material in this area will be sucked into the water pump and accelerate impeller wear, perhaps plug a cooling passage. Once media blasting is done, go ahead and pull the gearcase apart to clean and relube internals.December 7, 2017 at 5:21 pm #68360quote FrankR:Hm-m-m-m-, kind of a judgement call on the pitted crank. I would be more concerned at why is it pitted in the first place? Might be concerned enough to open it up and check the bearing for pitting. That can be fatal.The baffle plate is supposed to keep water, exhaust, and nasty away from the end of the crankshaft & seal area. Opinions vary as to how effective it is. I’ll let others give theirs.

Frank makes a good point. Rust/pitting in this area is a peculiar situation, and you would want to investigage just why this happened. Did the engine go under water and get left out "to dry up"? Is there a problem in the lower seal area that caused water to be pumped up to this area?

Perhaps a prior owner had water in his fuel, the engine stalled out and was left to sit with water in the crankcase. In any event, the damage is probably not limited to what you can see on the crank, other bearings/surfaces were probably affected. I surely don’t want to scare you into pulling the powerhead apart, but it might be worth just pulling off the intake manifold to have a better peek at the crank/rods/bearings. It sounds like you are putting a lot of effort into a cosmetic restoration as well, just don’t want you to have to pull the thing apart after doing a nice paint job.

A judgement call indeed.December 7, 2017 at 5:28 pm #68362Hi All,

Thanks for all the replies.

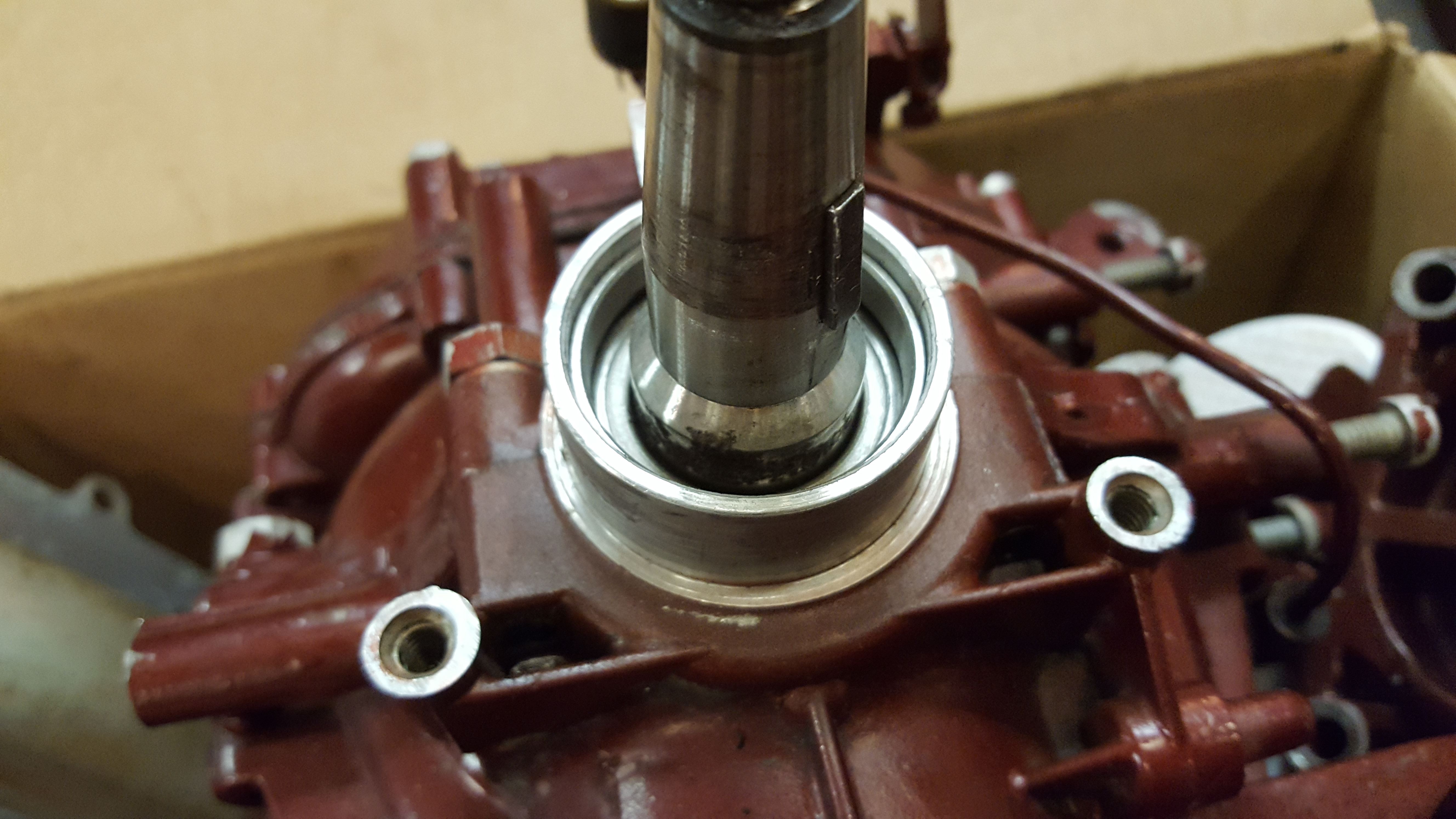

The black on the crankshaft is definitely pitting. I tried a q-tip and alcohol to get it off, and it came out kind of rusty color. I also tried scraping with a dull hobby knife and it is not seal residue on the surface. The old seal looks decent on the inside, but it did get a bit mangled during removal. I’ll try to post a photo later today.

I do know about the shift rod seal, and was able to pull the brass retainer without damaging it (shaved down bolt from inside). All of the brass gear case bushings are smooth and tight, just black in some areas so it sound like they will be ok.

I guess I’ll start researching cracking open the crankcase. ) ^ :

@Ed, I responded to your PM.Thanks!

-

AuthorPosts

- You must be logged in to reply to this topic.