Home › Forum › Ask A Member › Oily flywheel

- This topic has 19 replies, 9 voices, and was last updated 5 years, 11 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

March 1, 2019 at 10:04 am #169968

I have a 1958 evinrude 5.5 (model 5516)

And have quite a bit of oil under my flywheel and around magneto

Usually this would point to top crank seal leak but I dont show it having such a seal from parts diagram

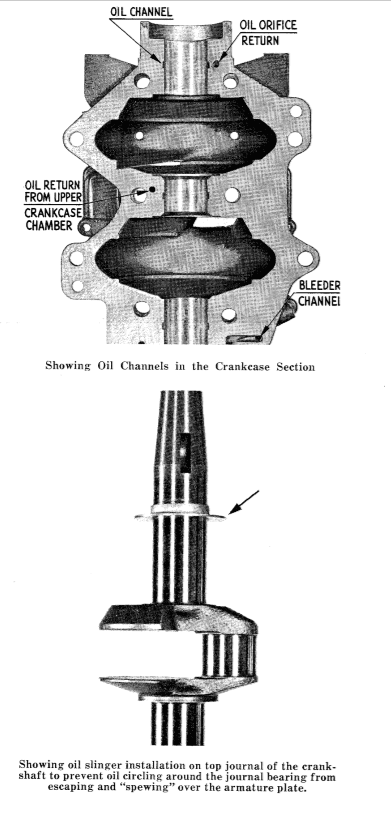

Any ideas what ir might be causing the leak and/or how to approach itMarch 1, 2019 at 10:27 am #169971Correct, there is no seal. Only a slinger that throws the oil off the rotating shaft. From there, it is sucked back down to the intake manifold through drillings in the crankcase. They only made a few millions of them that way, so can’t all be bad.

I suggest you check for excessive bearing looseness. If that is ok, clean it up and run it. Blow through the crankcase drillings, if it will make you feel better.

March 1, 2019 at 11:10 am #169979see pic from red book

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 11 months ago by

Mumbles.

Mumbles.

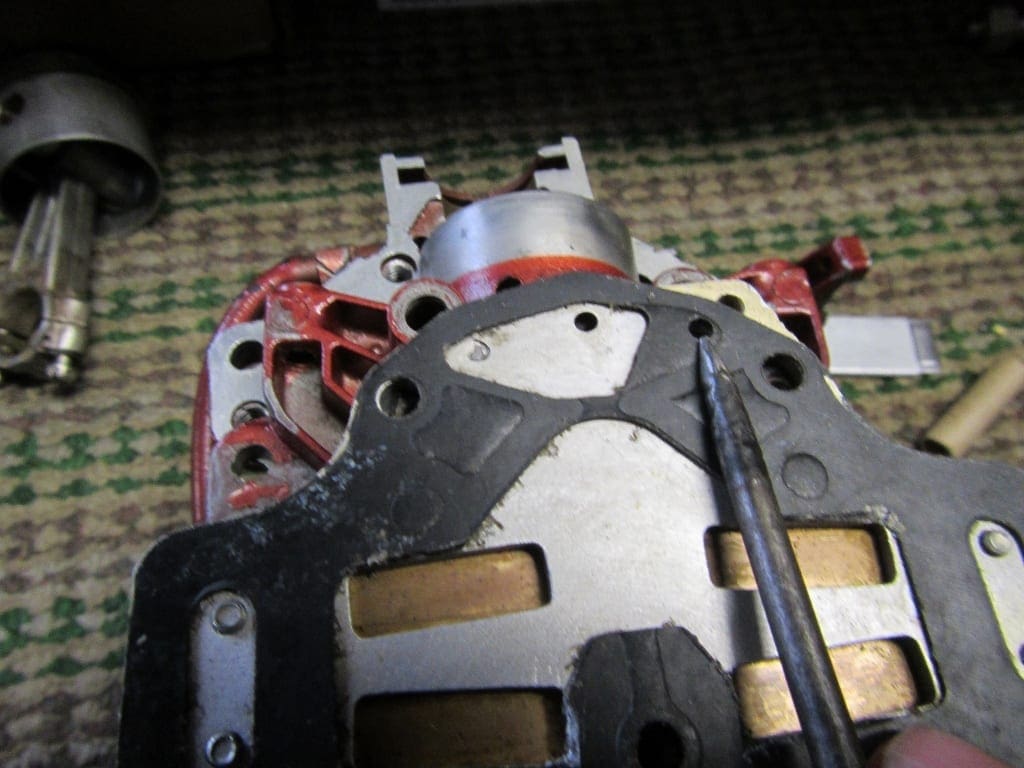

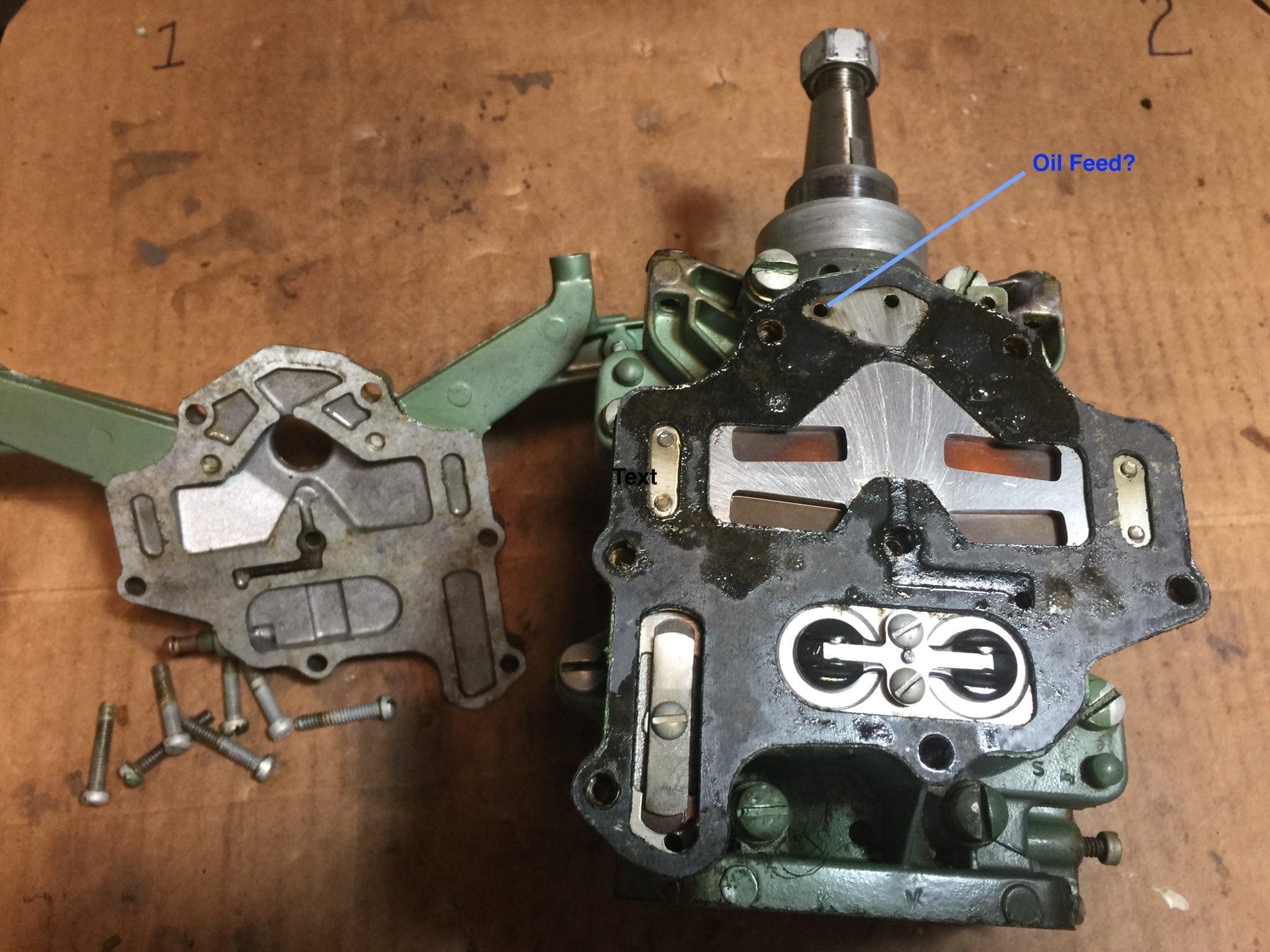

March 1, 2019 at 2:56 pm #169996Crosbyman is right on! I have one of those 5 1/2s apart right now. The slinger knocks the oil down that leaks by the bearing. There is a drilling that takes the excess oil and drains it back into the carburetor side of the reed valve. Check that drilling for blockage. Some times to much sealent on the reed plate, blocks the oil return hole. OMC has a oiling system that brings extra oil to the main bearings. That system uses crankcase pressure to circulate gas/oil mix through the engine. You probably seen the hose going from the bottom main bearing to the top bearing. Extra oil/gas goes back through the engine.

dale

March 1, 2019 at 3:02 pm #169997Would the pressurized fuel tank conversion have anything to with causing it

March 1, 2019 at 4:21 pm #169999Would the pressurized fuel tank conversion have anything to with causing it

I can’t imagine how it would..

March 1, 2019 at 4:41 pm #170001Trying to send some pictures. Make sure this hole is not blocked. This system of drillings should catch a bunch of oil if it is working correctly.

dale

-

This reply was modified 5 years, 11 months ago by

Mumbles.

Mumbles.

March 1, 2019 at 6:21 pm #170007Dale,

Was looking at your photo #1 and made me recall when I was replacing the manifold and reed plate gaskets on my ’54 CD-11. Judging by location of the upper/lower bearing oil feed hose, your motor is a 1958. Looks like the oil feed drilling to the reed plate is in a different location between the ’54 and ’58?Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."-

This reply was modified 5 years, 11 months ago by

Mumbles.

Mumbles.

March 1, 2019 at 7:32 pm #170013Was it stored upside down?

March 1, 2019 at 7:59 pm #170015Don’t know about my motor. It was sitting on a dolly when I found it.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."-

This reply was modified 5 years, 11 months ago by

Robert Wight.

Robert Wight.

-

This reply was modified 5 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.