Home › Forum › Ask A Member › Omc 22 cubic inch 25 hp differences

- This topic has 17 replies, 8 voices, and was last updated 5 years, 5 months ago by

daveh.

-

AuthorPosts

-

November 19, 2019 at 7:23 pm #187555

Steve D,

That is exactly what I did.

I used the original 1969 bypass/transfer cover bolt, at the same location on the new replacement, and drilled out to the same diameter as the 1969 had in the case, effectively making that part of it the same as it was originally for 1969. It was a thin wall that I had to drill through, and then I was able to draw through it as it was on the original powerhead. Then the hose goes from the intake to that breather bolt just as it did.

I assume that is all I would need to do, and all else will be fine.

I also assume that the Original 1969 carb jetting can also be used?-

This reply was modified 5 years, 5 months ago by

daveh.

November 20, 2019 at 10:09 am #187579Well, I am wondering if the different passages, or lack thereof, on the new powerhead will affect the way that 1968 drain system was supposed to work. It maybe that the passages/check valves are not longer there on the new powerhead leaving the old drain system inoperative. I would have to have a very close look at the new powerhead to see if it would work properly. I’m guessing that an actual replacement powerhead for this older model would have detailed instructions on how to adapt/deal with the drain/recirculation system…

Frank is so right, that new recirc system was poorly thought out and made the engines idle like crap. One rich cylinder, the other one is lean. So, trying to “dial in” the low speed needle for smoothness usually resulted in a lean spit. Usually, you had to leave the engine a bit rich to avoid the sneezing, which lead to plug fouling, especially on low tension models. Just seems like that single recirc hose should have been split and delivered equally to both bypass covers….

November 20, 2019 at 5:13 pm #187616We would sometimes eliminate the bypass cover nipple and route the hose up to the carb. We’d take a press-in hose nipple and drill a hole in the top of the carb for it, right behind the throttle plate area. They didn’t run exactly like a watch but they were better than the OEM idle. We were also then able to adjust the idle mixture enough so that both cylinders were, at least even. I don’t remember if that was OMC’s idea or ours?

Long live American manufacturing!

November 20, 2019 at 9:53 pm #187656Yes, I have seen this done before, makes more sense than routing it to just one cylinder….

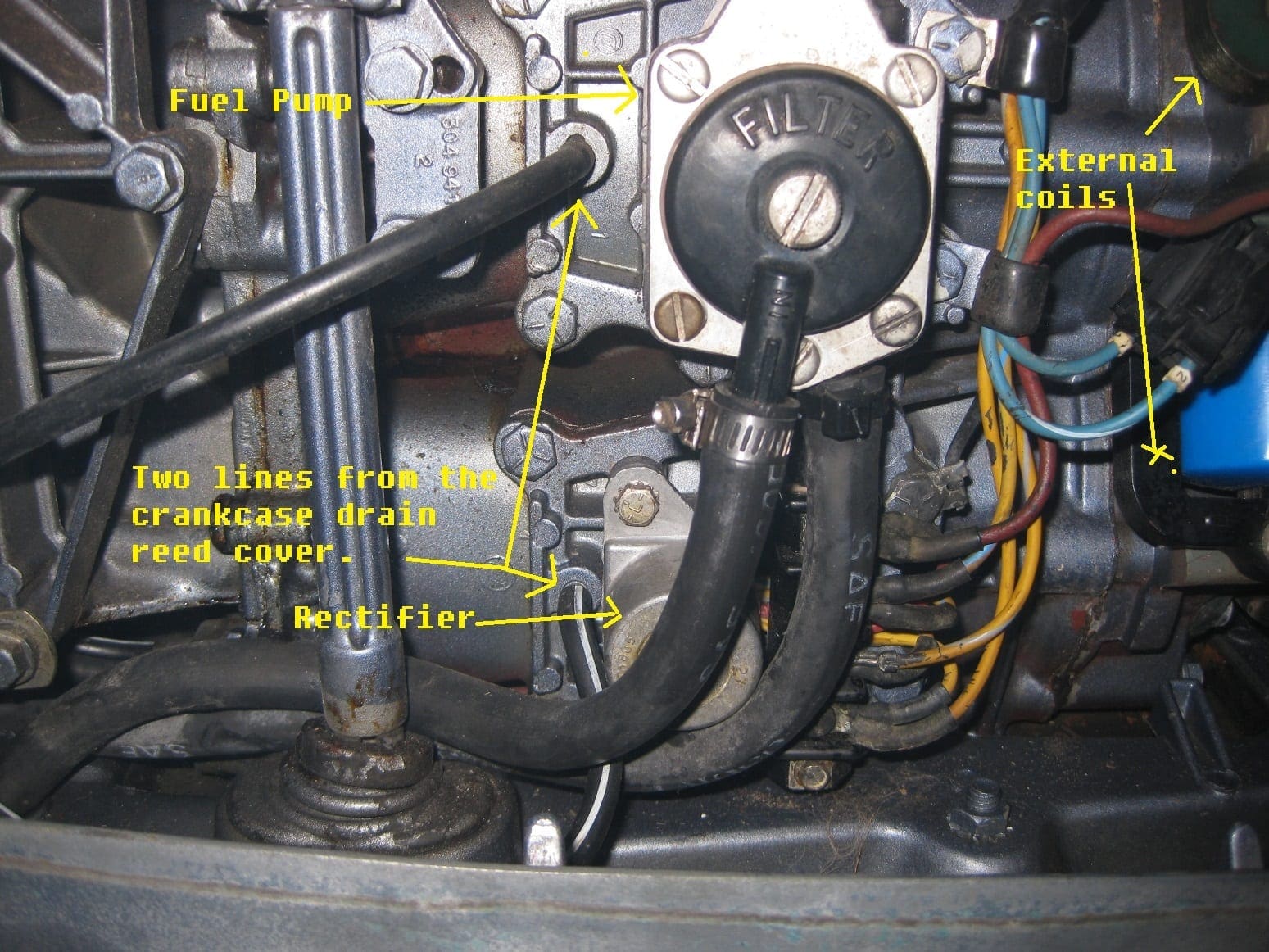

November 20, 2019 at 9:54 pm #187657I found this interesting.

Here’s how a 40 hp 1974 Evinrude ‘Jungle motor’ does the recirculation system. I believe the top cylinder goes to the bottom for recovery and the bottom goes to the top.

November 20, 2019 at 10:00 pm #187661Jungle motor?? I’m guessing the bottom cylinder recirc hose goes to the top cylinder and vica versa…

November 20, 2019 at 10:02 pm #187665November 24, 2019 at 5:44 pm #187981I think it’s gonna work out okay. The powerhead was new in the box. No instructions, other than break in, and retorque the head bolts. Got it from Ed Elliott a few years ago at Tomahawk and I was waiting for the right outboard to use it on.

Only way to find out is to run it 😉

I won’t know until spring when I fire it up. -

This reply was modified 5 years, 5 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.