Home › Forum › Ask A Member › OMC Carburetor

- This topic has 15 replies, 8 voices, and was last updated 3 years, 11 months ago by

Shamus.

-

AuthorPosts

-

August 1, 2021 at 9:53 pm #244087

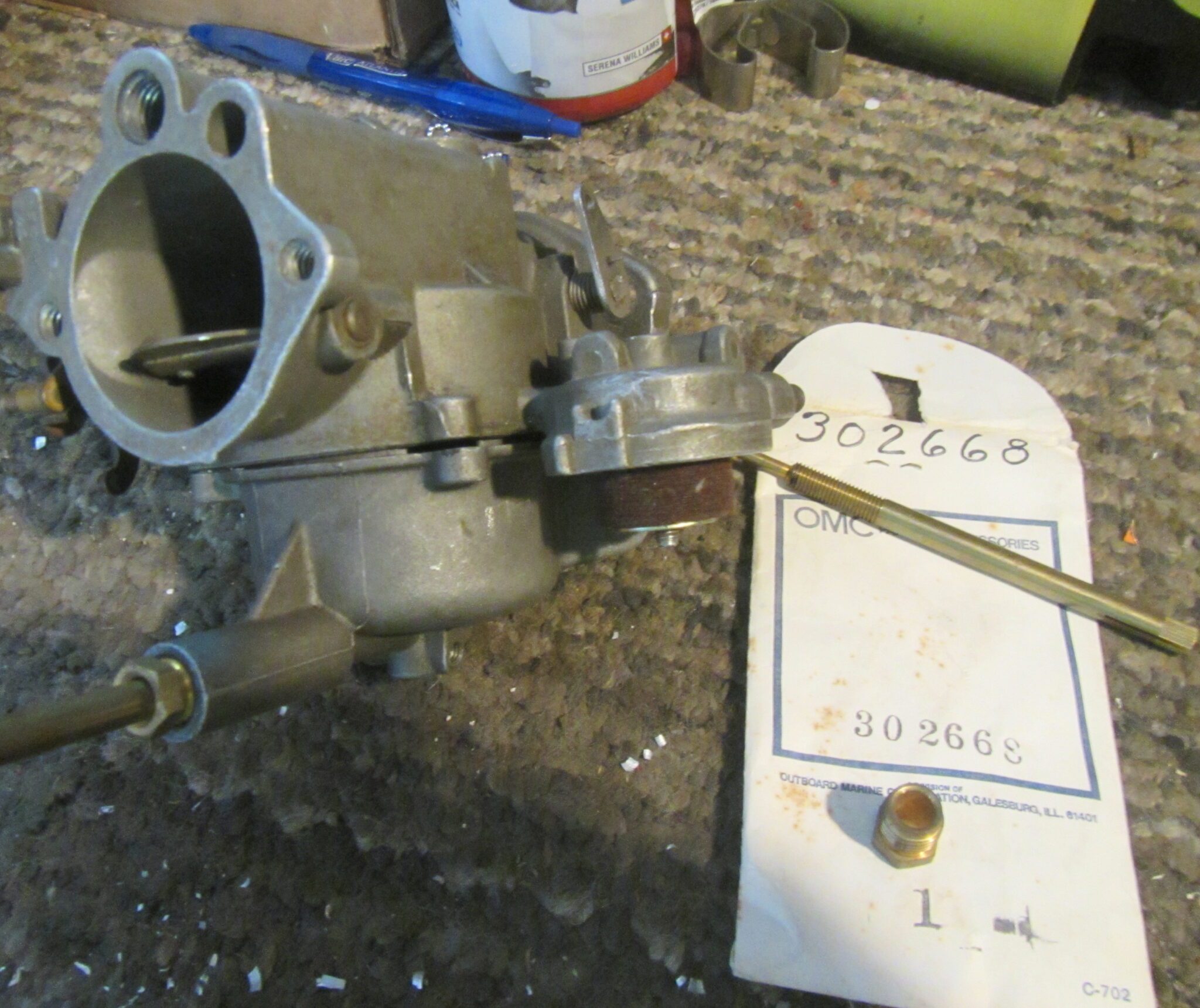

I found this carburetor at a rummage sale it was missing a few parts. I have a parts list for the 1951/52 25hp OMC which I thought this carb was so, I ordered a new needle and plug. WRONG! I have no treads to screw the slow speed needle into. Anybody recognize this carb? Also a parts list so I can find the right parts to get this puppy working again?

dale

get’em wet!… don’t let’em set!

August 1, 2021 at 10:24 pm #244090That might be a different model carburetor which uses a bushing that slides in the carburetor body and accepts the threaded needle valve. The bushing has the needed internal threads and is held in place by the compression of the packing washers as the needle retaining nut is snugged down.

Might not fit your 1952 though.

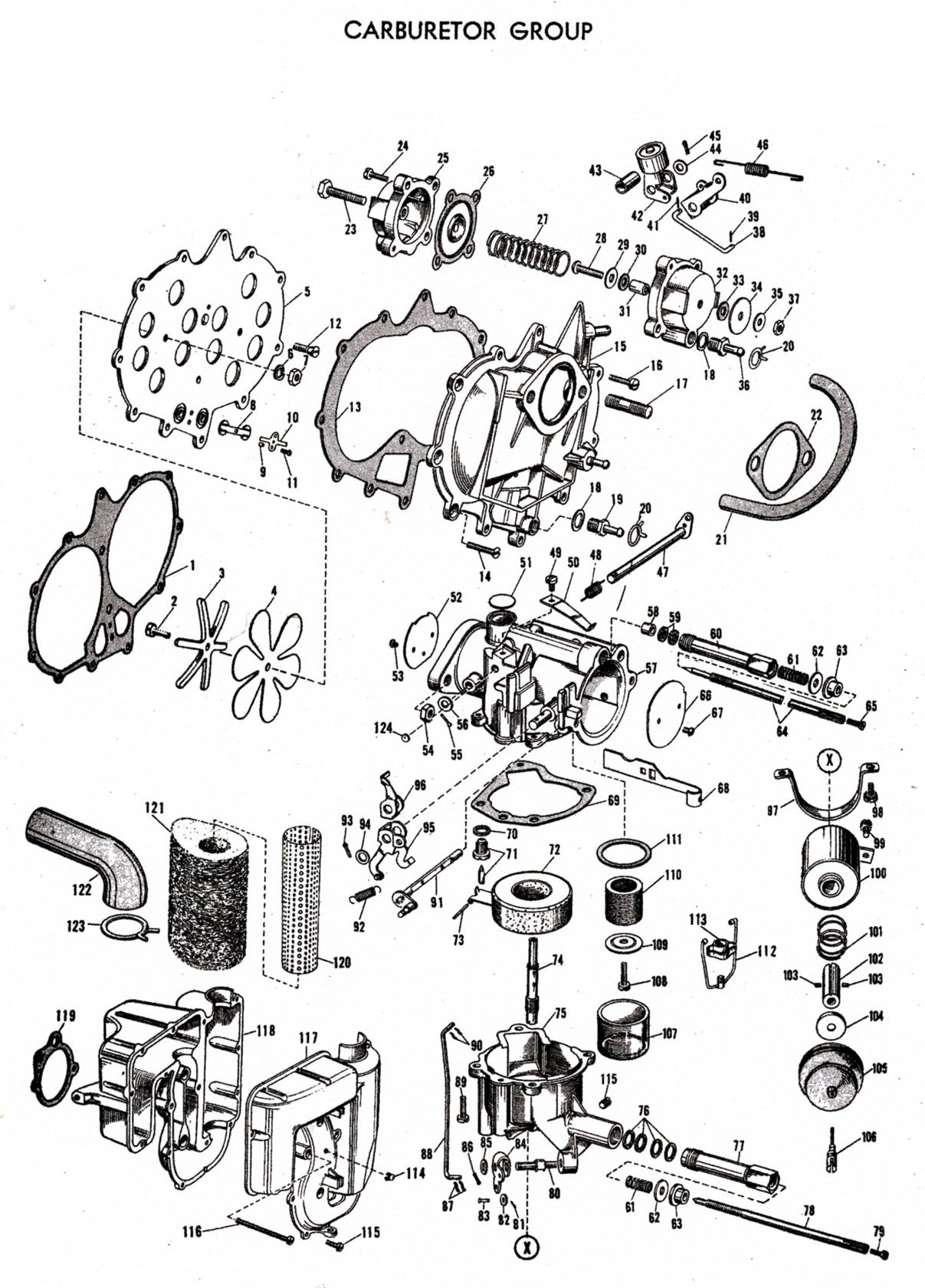

You can see the bushing #34 on this parts diagram:

https://www.boats.net/catalog/evinrude/outboard-by-hp/18hp/18802a-1968/carburetor-group

-

This reply was modified 4 years, 4 months ago by

seakaye12.

seakaye12.

August 1, 2021 at 10:25 pm #244092August 1, 2021 at 10:48 pm #244095WOW! I wish I would have left it set! That #58 would have to be in the housing about 2 1/5″! The plug screws in at the very front of the carb. Looks to be about3/8″. Maybe a spacer between the packing and the needle sleeve? I just don’t understand!!

thanks dale

August 1, 2021 at 11:25 pm #244097WOW! I wish I would have left it set! That #58 would have to be in the housing about 2 1/5″! The plug screws in at the very front of the carb. Looks to be about3/8″. Maybe a spacer between the packing and the needle sleeve? I just don’t understand!!

thanks dale

I’m confused about what you are concerned about….Are you concerned that the threaded sleeve isn’t long enough? Are you making this judgement just by the picture?

August 2, 2021 at 5:03 am #244104Pre-assemble 58, 59, and 60 onto the needle valve, threading 58 on a few turns. Then push the whole sub-assembly into the carb and tighten the packing nut enough to keep the threaded sleeve from spinning. Then screw the needle in till lightly seated and back it out 1-1/2 turns. Finish up by tightening the packing nut for desired friction after final adjustment of the needle at idle.

August 2, 2021 at 7:36 am #244108I gotta find those parts 58 60 and 64 because mine were gone!

Maybe ede will have them gonna check.dale

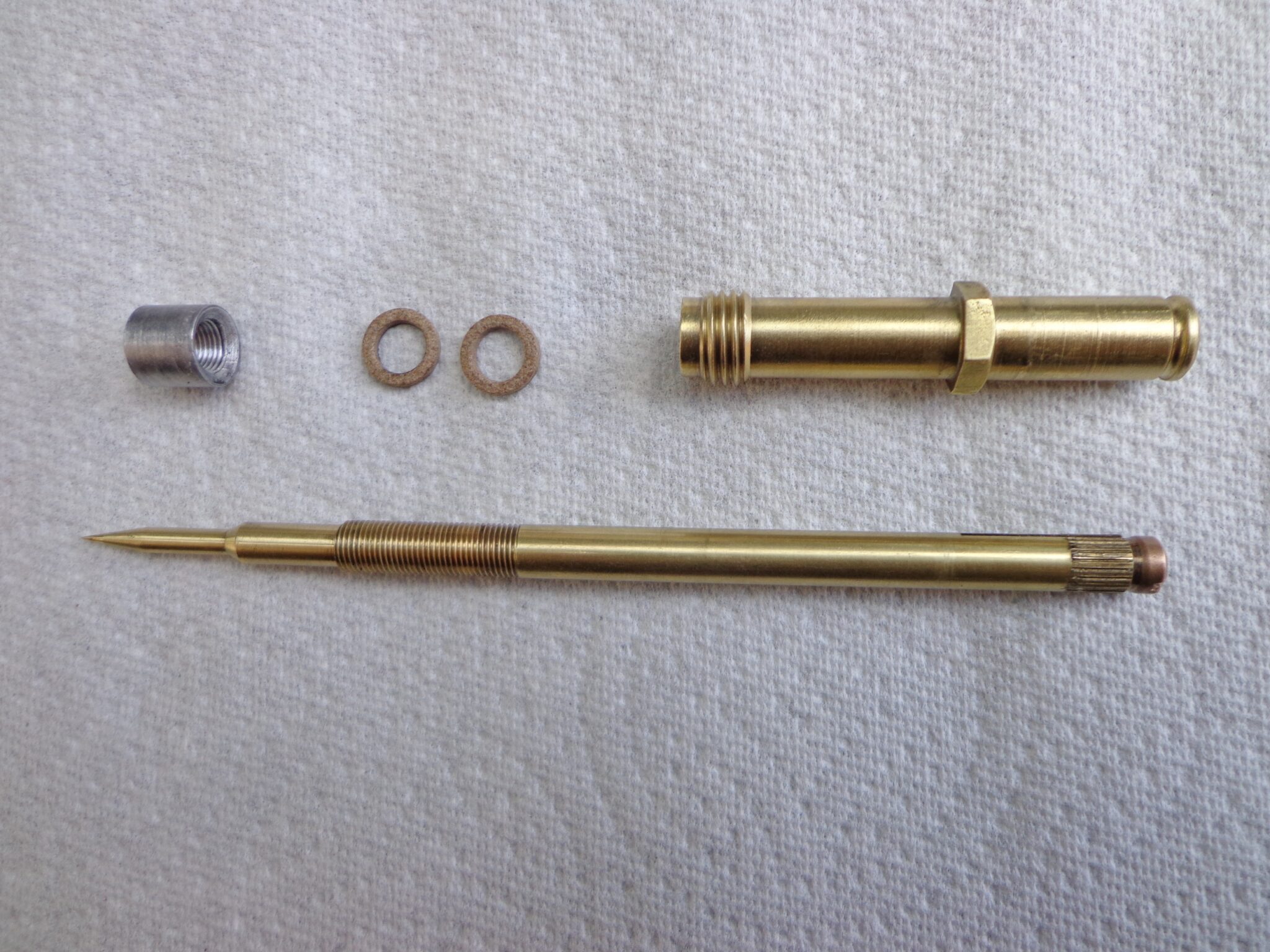

August 2, 2021 at 1:13 pm #244141Here’s what the pieces you need look like. The sleeve would be easy enough to make if you have access to a lathe and a 1/4 X 40 tap. Concave side faces the packing washers.

EDIT: That would be concave, not convex.

August 3, 2021 at 8:57 am #244195Here’s what the pieces you need look like. The sleeve would be easy enough to make if you have access to a lathe and a 1/4 X 40 tap. Concave side faces the packing washers.

EDIT: That would be concave, not convex.

Mumbles would you have the part numbers for the components in your picture? I have no machining abilities and not many part numbers from pre ’56 motors. I went to Gary’s share site and could not find these particular pieces.

thanks dale

August 3, 2021 at 11:14 am #244206I worked on a 1961 10 HP recently where I couldn’t get that #58 to stop turning when inserted into the carb, so I couldn’t screw in the needle. Part 60 pushing the packing against part 58 would not hold it. I dried everything out with Q-tips and put a coating of a very thin locktite sealer on the outside of #58 and inserted it all the way in. After letting it sit overnight to cure, everything works fine. I just hope I never have to take #58 out because breaking loose the Locktite may be hard to do. This is only one carb out of dozens I’ve worked on that gave me this problem.

Dave-

This reply was modified 4 years, 4 months ago by

outbdnut2.

-

This reply was modified 4 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.