Home › Forum › Ask A Member › OMC Shifter Cog

- This topic has 5 replies, 5 voices, and was last updated 6 years, 8 months ago by

labrador-guy.

labrador-guy.

-

AuthorPosts

-

April 16, 2019 at 4:26 pm #173533

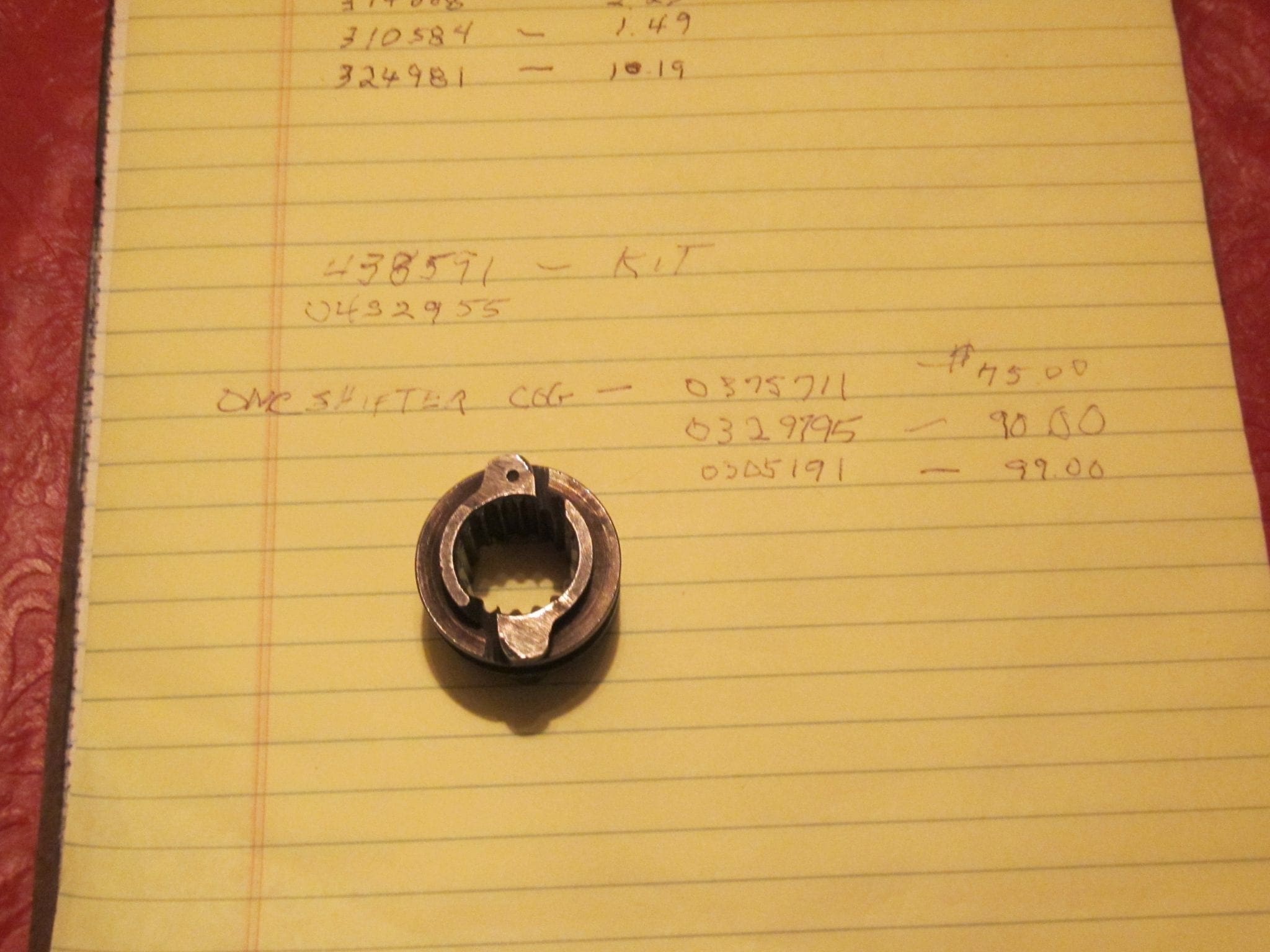

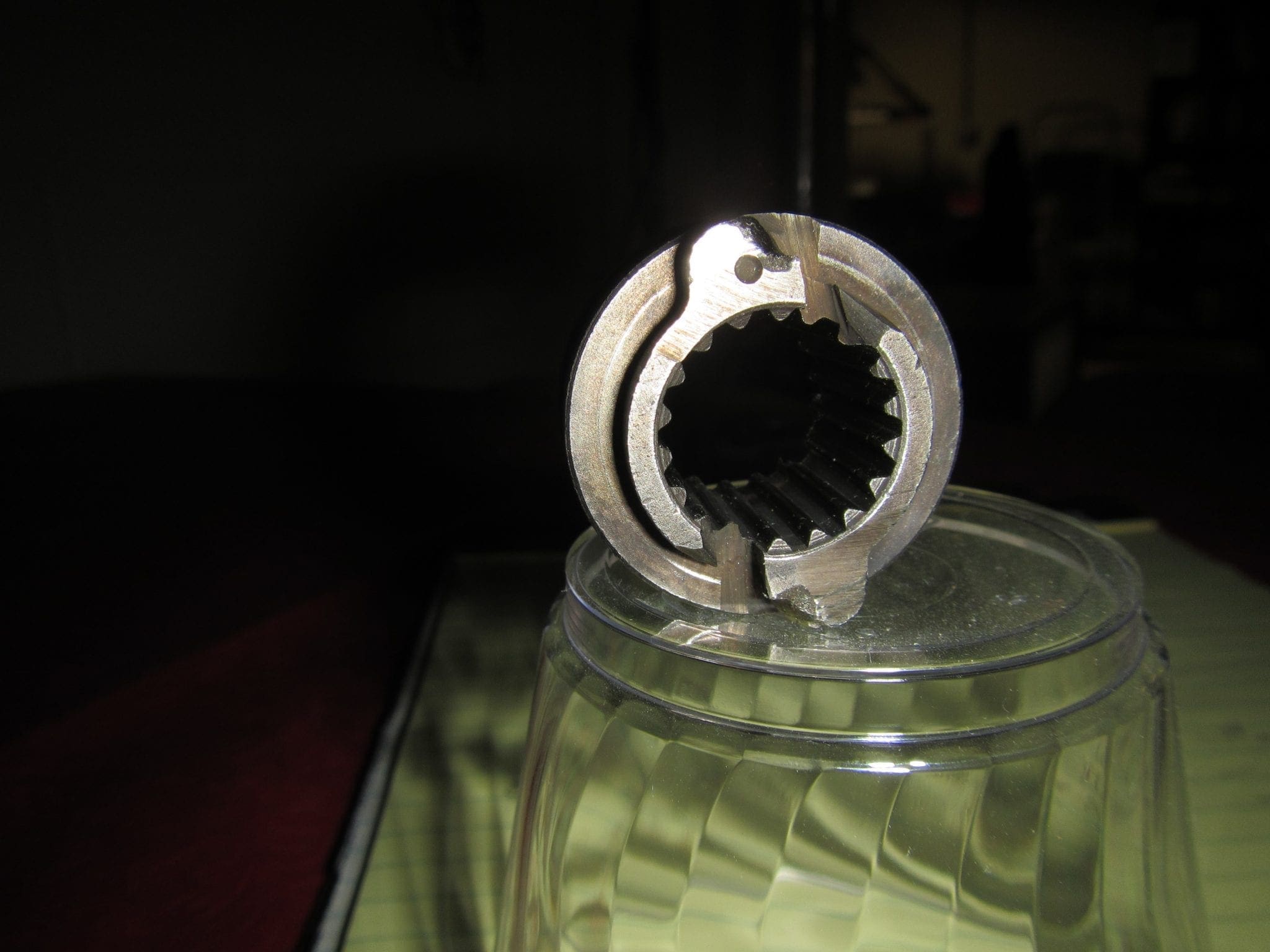

Hi guys, I just pulled down a 1958 OMC five bolt gearcase. The shifter is shot, corners are hammered bad. A previous owner did some modifying and it got me wondering if maybe someone out there in outboard land has tried a fix of some sort for these shifter cogs? A new one is pushing a hundred bucks. I would be lucky to get that for the whole motor! Has anybody put some weld on the rounded off corner? Did some grinding and filing? I know there are a lot of cheep pikers out there like me….soooo any ideas?

dale

April 16, 2019 at 4:40 pm #173538Check out Ebay. These are much less than $100, More like 25-35.. But first check where the dogs mesh into the gears. The gear corners may also be damaged.

April 16, 2019 at 6:27 pm #173583Don’t know what they were up to here….Look for a used clutch dog/forward gear, affordable ones are still out there….Don’t waste time trying to resurrect this thing…

April 25, 2019 at 10:16 am #174351Dale,

Apparently the option to quote a post is temporarily out of service like the highlighting of unread posts and topics. Anyway, I’m not too confident in rebuilding the drive dogs with weld. Those gears and clutch dogs are hardened alloy steel. Not sure how a mild steel wire or rod would alloy with that part to begin with. if it did, you would lose the hardness and be left with a soft(er) part which would almost certainly not stand up to the task.I have not tried it yet, but I think you would be better off grinding the mating surfaces back some to get rid of most or all of the rounding on the clutch dog and the gear drive cogs to match. it may be a tedious process to make it right as you would have to take care and time to use marking fluid and even out the surfaces from side to side to get them as close to even as possible. It would take some time and a steady hand, but I would imagine the hardness of those heat treated gears would be to a sufficient depth to allow enough material to be removed to get good surfaces back. Just a lot of work to get it back to good when good parts are still out there. I may try it sometime just to prove to myself I can do it.

-BenOldJohnnyRude on YouTube

April 25, 2019 at 12:35 pm #174361I thought about a grinding fix as well.Found a new dog and new forward gear for $45 and free ship eBay.

April 25, 2019 at 8:22 pm #174381I found out that shifter thing is made in three parts. The cogs are welded to the center part where the fork goes. If you look closely you can see that it is made in pieces. Then welded, one on each side. Machinist guys could make some out of harden steel. Need one of those resistance welders to stick it on the center part. We have some really great talented people in this club and I thought I would ask if anyone did some experimenting! The one pictured is toast for sure. I found a much better one in my parts boxes. Little that I am gonna run it it should last a long time. Thanks for looking and replying!

dale

-

AuthorPosts

- You must be logged in to reply to this topic.