Home › Forum › Ask A Member › OMC Transom Screw Plate Retainers removal

- This topic has 8 replies, 8 voices, and was last updated 8 years, 6 months ago by

cgodfrey.

-

AuthorPosts

-

June 28, 2017 at 5:55 am #7461

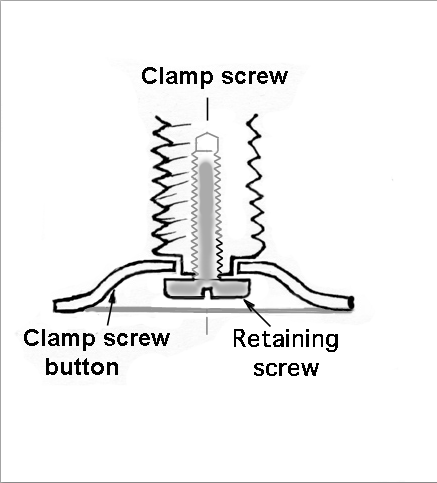

Keen viewers will notice those are flat fender washers instead of the correct plates on those transom screws.

I’d hate to see the last guy’s transom. Crunch.I’ve replaced plates when they’ve been missing, (I believe crushing down on a socket to flatten the retainer is the technique) but I’ve never had to actually take a plate OFF.

What’s the best way? Just break the retainer with a side cutting pliers? What a waste of good retainers.

June 28, 2017 at 6:20 am #60516If you are familiar with the way the retainers look when new, you can usually reuse them a couple of times. Use a screwdriver to bend them back to the original "buttercup" shape and they will come off.

June 28, 2017 at 6:57 am #60517Be gentle removing and reusing those retainers. I just looked them up on M E , PN 302420 is still available …$12.99.

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonJune 28, 2017 at 12:55 pm #60525I have NOS retainers and cups. 2 cups and 2 retainers $22 mailed to you if you need them. Remove the old retainers by carefully prying them of- by bending them back to a U shape. Quite often they are re-usable, If not you can always e-mail me. Stan Jackson in ohio

1419 589 58one8June 28, 2017 at 1:03 pm #60528If I have time, I’ve taken to just backing out the handle until the retainer pops off. I then grind the nub on the thumbscrew flush. Then, I drill and tap a hole for a 1/4-20 bolt, usually 1-inch long. When I tap the hole, I stop short of bottoming out, enough that when the bolt is threaded into the hole, it hits the less-tapped area of the tap’s taper, which helps lock it into place. A drop or two of thread-locker works, too. Depending on the cup used, I’ve ground the bolt head a bit to clear the recess so the head doesn’t dig into the transom. Leave the bolt so that it doesn’t tighten up against the cup – you want the cup free to rotate, but not too loose.

June 28, 2017 at 1:51 pm #60530I have tired Chinemalker’S method (tapping & bolting in the cup) …worked perfectly !

Joining AOMCI has priviledges 🙂

June 28, 2017 at 4:32 pm #60537June 29, 2017 at 2:15 am #60576Thanks Mumbles – I like yours better than mine. You should start submitting articles to our Outboarder. . . 😀

June 29, 2017 at 11:58 am #60586

June 29, 2017 at 11:58 am #60586I WISH I had the machining talents for that, or even knew who to pester to teach me. Better solutions are awesome, and that certainly qualifies.

-

AuthorPosts

- You must be logged in to reply to this topic.