Home › Forum › Ask A Member › Opposed twin coil swap

- This topic has 17 replies, 6 voices, and was last updated 8 years, 7 months ago by

jim-moffatt.

-

AuthorPosts

-

February 24, 2017 at 5:45 pm #6413

How loose can the fit of the re-worked lamination bundle be in the hole through the new replacement coil?is a precise fit necessary for the coil to work?

February 24, 2017 at 7:10 pm #53520I’ve had it work with the coils sliding around easily, but they work better if you can stuff in enough laminations until they fill the opening. Here are a couple of things to consider: The laminations often have, by design, paint, oxidation, or some other insulation on them. So don’t polish them up before you put them back in. Also, if you are using two single cylinder coils on one set of laminations, the coils should be from the same manufacturer and they should be oriented the same way. The ground wires should be tied together and grounded to the mag plate. The point wires should be tied together, then go to the points.

Got pics?

T

February 24, 2017 at 7:57 pm #53521Sorry no pics,but it’s a Lockwood coil just like the one in the old thread on this forum.I am using two OMC replacements.Since I don’t have access to a milling machine,I was thinking of other ways to cut the core down enough to fit into the hole in the replacement coils.I just wanted to know how precise I had to be.

February 25, 2017 at 12:44 pm #53543February 26, 2017 at 9:33 pm #53583If the motor is a 62 or 72 T the swap is easy. If its an Ace or Chief the lams must be cut apart in a staircase fashion. There is an article on doing this in the Oct 2008 0r 2010 Antique Outboarder (the dates may be wrong but the article is there somewhere)

February 27, 2017 at 3:01 pm #53608I am now ready to cut the laminations from my old coil so that they can be inserted into the new ones.Can I simply cut the laminations one at a time with a hack saw and not worry about the space that will appear between the cut ends when they are re-assembled?I don’t have access to the relevant magazine articles and what info I have gotten elsewhere hasn’t made this clear to me.

February 27, 2017 at 4:14 pm #53609This link is to a Model A Johnson coil conversion

I did some time ago. Hopefully there is something

here that you’ll fin useful.

https://www.youtube.com/watch?v=gfRG_Zz_0gk&t=15sA "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

February 27, 2017 at 4:36 pm #53611Here is a link to the coil article Jim is referring to. You may have to click on it to expand it. http://i.imgur.com/CK2Rplp.jpg Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

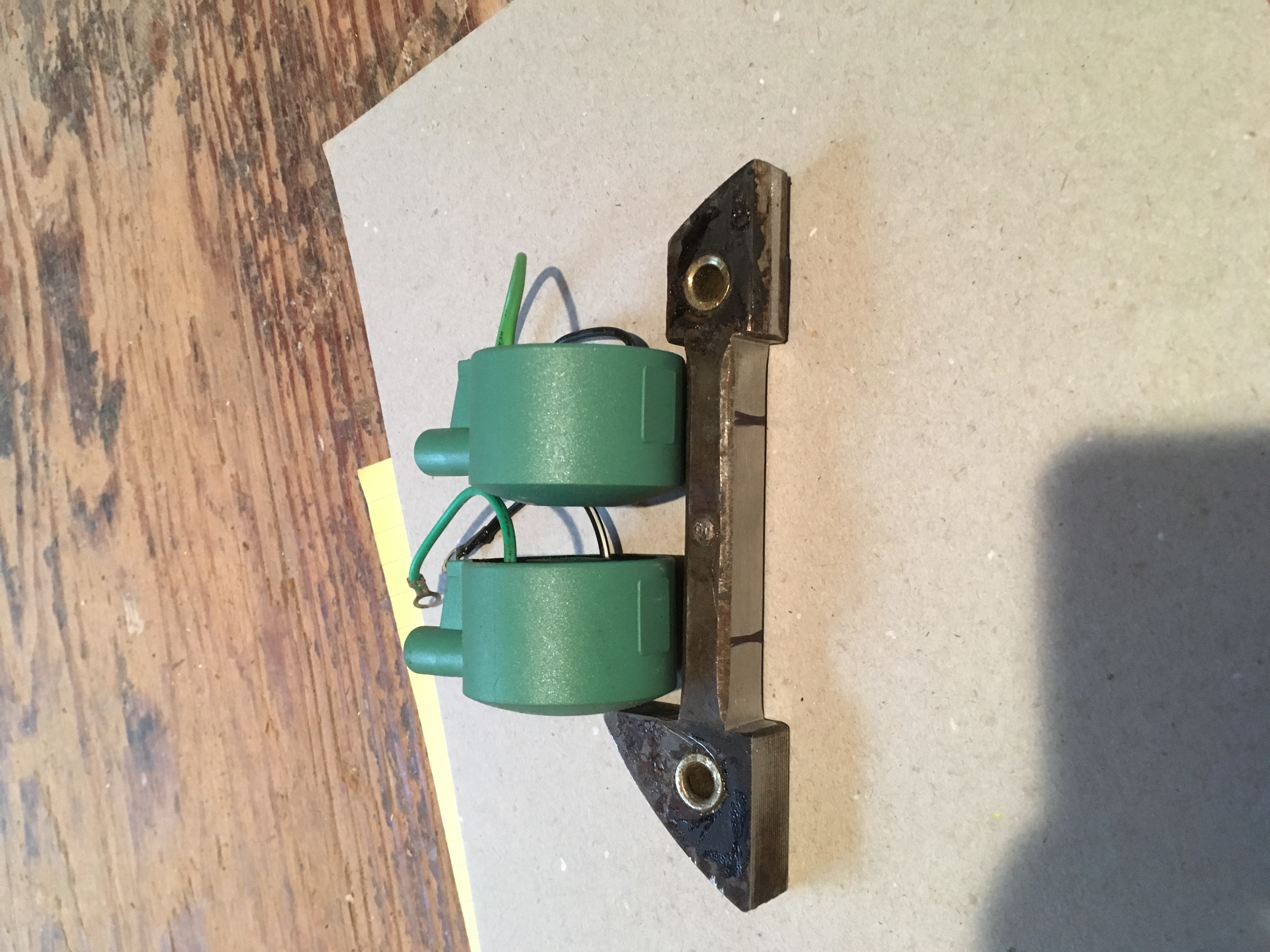

February 27, 2017 at 4:56 pm #53613Thanks Tubs.I have seen that one and it was a help.I am probably a little slow witted and overly cautious,but I still don’t get the cutting part.Here is a picture of my laminations trimmed to the right width.My plan is to cut every other lamination at either of the marked spots.(I know I won’t need all the laminations.)When I cut and re-assemble them there will be a gap at the cut.Is that an issue?

February 27, 2017 at 5:23 pm #53616quote Stanley:Thanks Tubs. I have seen that one and it was a help. I am probably a little slow witted and overly cautious,but I still don’t get the cutting part. Here is a picture of my laminations trimmed to the right width.My plan is to cut every other lamination at either of the marked spots.(I know I won’t need all the laminations.)When I cut and re-assemble them there will be a gap at the cut. Is that an issue?

I believe that is what Jim describes in his article.

He doesn’t mention the space being a issue but you

are correct in your belief the there will be one for

proper spacing of the shoes to fit the mag plate.

Some of the extras could be cut so there isn’t any

gap but I don’t think there are enough extras to

do them all.

A little slow witted?

It sounds to me that you have a really good

understanding of the procedure.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.