Home › Forum › Ask A Member › Opposed twin coil swap

- This topic has 17 replies, 6 voices, and was last updated 7 years, 8 months ago by

jim-moffatt.

-

AuthorPosts

-

February 27, 2017 at 9:04 pm #53619

Ok, Let me see if I can help here since I did this as well, and it was also printed in the Outboarder.

I recall having 13 "plates" or laminated strips that would be needed to fit inside my OMC coil conversion that I did on my Neptune Mastertwin.

When the core is together, I drilled 2 holes, about 1/8" in diameter, one in each end, so that after assembly, those 2 holes will allow a screw to be used to aid in holding it all together properly.

after drilling the holes I separated all the pieces, numbering each plate on both ends of the plates, started from the bottom with #1 and the next plate is #2 and so on…..

So now to cut, take plate one and simply band saw it at a point so that the cut will be hidden when assembled INSIDE the left coil.

Plate 2 gets cut with a band saw so that its cut is hidden INSIDE the RIGHT coil.

Plate 3 gets cut so its cut is INSIDE the LEFT.

Alternate cuts to each plate in succession until you are all done.

Stack these plates, in numerical order, in relation to which side they will be.

The left pile is a short #1, long #2, then short #3 and so on.

The right pile will have a long #1, a short #2 and a long #3 and so on…

I learned this doing mine so follow this and it will help.. debur, file or sand the ends you have just cut, this is important as it will allow easier assembly of the plates into the coils.

The goal is NOT to shorten these plates any more but to allow them to slide together easier.Now to assemble:

Take the left pile with short #1 on the bottom and long #2 the short #3 until you have the complete left stack…stacked…

You should have 2 holes in every plate, a large hole that was originally there to mount the original coil to the mag plate and the second little hole I asked you to drill. Use a bolt thru the larger of the 2 holes to hold the laminates together.

Now do the same thing to the right pile of plates.

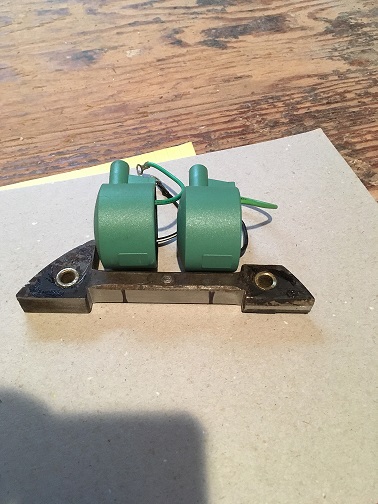

Now you should have two stacks of plates semi assembled.

Install the left pile thru one coil, and the right pile thru the right coil, MAKING DANG SURE BOTH COILS are oriented the EXACT SAME WAY!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

You might notice I made that a VERY IMPORTANT note…

Now you have to slide the right side of plates and coil into the left side of plates and coil, ensuring the plates are lined up properly.

Once all that is done you can install a rivet or a small screw into those tiny holes you drilled, those will give you the proper alignment length you have to have.

I hope this has helped, I can see it in my mind like it was yesterday, but it was nearly 10 years ago that I did this. It works, Thanks to Jim Moffatt for encouraging me to attempt this conversion…

If I can answer any questions let me know.

Best

Richard White

http://www.richardsoutboardtools.com

classicomctools@gmail.comFebruary 27, 2017 at 9:06 pm #53620quote Stanley:Thanks Tubs.I have seen that one and it was a help.I am probably a little slow witted and overly cautious,but I still don’t get the cutting part.Here is a picture of my laminations trimmed to the right width.My plan is to cut every other lamination at either of the marked spots.(I know I won’t need all the laminations.)When I cut and re-assemble them there will be a gap at the cut.Is that an issue?Stanley, if those marks fall in a location that will be INSIDE either coil, roll with it as that is how it should be…

http://www.richardsoutboardtools.com

classicomctools@gmail.comFebruary 28, 2017 at 1:54 pm #53636The gap left by the hacksaw will not be a problem. The staggered cuts

are what stops it from being a problem.February 28, 2017 at 2:15 pm #53638Thanks to Tom,Jim,Richard,and Tubs for all the help and re-assurance.You gentlemen are the best!Finished putting everything back together late last night and it makes spark again.

March 3, 2017 at 12:43 am #53735I`m in the process of doing this to a Lighttwin model 442. Does it matter the positioning of the coils? That is does it matter if the plug wires come out at the top or bottom providing there is enough clearance. If I position it to come out at the bottom the condenser will be in the way. I`m going to press 2 OMC coils off of the laminates tomorrow. I have a old one to practice with.

March 3, 2017 at 1:00 am #53737March 18, 2017 at 10:31 am #54505I finally got this put back together and now have spark. What a confidence booster. 😛

quote elgin2:I`m in the process of doing this to a Lighttwin model 442. Does it matter the positioning of the coils? That is does it matter if the plug wires come out at the top or bottom providing there is enough clearance. If I position it to come out at the bottom the condenser will be in the way. I`m going to press 2 OMC coils off of the laminates tomorrow. I have a old one to practice with.May 9, 2017 at 12:15 am #57323the gaps are not an issue. The magnetic flux bypasses them by jumping to the next lamination which doesnt have a gap.

thats also why the gaps are staggered. -

AuthorPosts

- You must be logged in to reply to this topic.