Home › Forum › Ask A Member › Question For FR

- This topic has 8 replies, 6 voices, and was last updated 9 years, 1 month ago by

chris-p.

-

AuthorPosts

-

March 28, 2015 at 4:00 am #1044

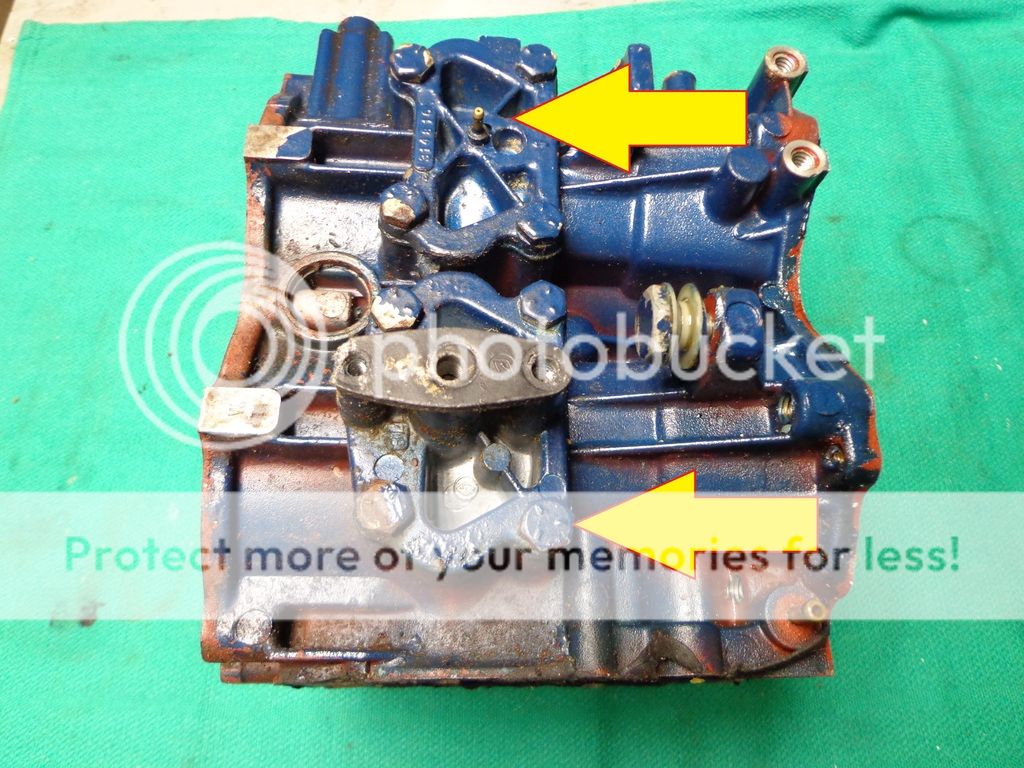

On another post, Frank mentioned replumbing the crank case drain system on 70’s 18-20 horse motors to improve the idle. This motor I have apart here is a ’72 Fastwin 18 horse with the manifold drain hooked to the upper bypass cover so I’m thinking it’s a candidate for the fix.

The right bottom bolt in the lower bypass cover will go into the exhaust cavity if I drill it out. Just checking to make sure I got it right as I can make a bolt with a nipple on it to replace this one and plug the nipple in the bypass cover. Is that the right way Frank?

March 28, 2015 at 8:38 am #12907

March 28, 2015 at 8:38 am #12907Yep, that’s the plan

FrankMarch 28, 2015 at 12:06 pm #12911Thanks for the nice visuals on that Mumbles. That compliments Frank’s explanation perfectly!

March 28, 2015 at 2:19 pm #12919What does this accomplish moving it to a lower point? I understand you said idling. Is the new plumbing larger more volume?

Does this work on 18s only or does it benefit

10s and 7.5hp as well? Very interesting.

ThanksMarch 28, 2015 at 2:39 pm #12920Seems like only a few days ago that I posted that, but already I can’t find it. So here is a re-run:

From around 1950 thru 1967 the crankcase puddle drains led to a channel and passage in the front of the casting and were dumped into the exhaust housing and lake. And the motors ran very well. Then came the years of “smog control” in cars and they ran like crap. Outboards didn’t escape either. A mad rush was made to eliminate emissions into the water, and some of them ran like crap also.

OK, here is the plan.

Starting 1968 part of the drainage system was eliminated, and what was left was routed through a hose to a fitting in lower bypass cover….actually one of the bypass cover bolts which was a combo bolt and fitting. From there it went through the casting and into the exhaust area, where the heat was supposed to evaporate and "smoke off" some of the fuel & oil. The rest still went out the exhaust into the lake.Starting 1973? They re-routed it into a fitting in the upper bypass cover so it would be drawn into the cylinder and burned. You know how well that worked out. Result was poor idle because the upper cylinder ran richer then the lower one, making carburetor mixture adjustment difficult or nearly impossible. Lean it out enough to prevent the rich upper cylinder, and the lower one lean sneezed.

What we are going to do is revert your motor back to the 1968 system. It won’t run as well as the pre-1968 models, but the only way to do that is with a pre-1968 powerhead. To do this you will need a 3/32" aircraft (extra long) drill bit and a special fitting and gasket washer. The fitting is part number 315230 and washer is 303630. Try a dealer. A decent hardware store should have the drill bit.

Remove the bolt from the lower front corner of the lower bypass cover. Before you go any further, screw your fitting and gasket into the hole and attach a piece of hose. Can you blow through it? If you can, it already is drilled, so do NOT continue with the drilling step in the next paragraph. But if you cannot blow through it, it needs to be drilled, so remove the fitting and continue.

What we are going to do is drill a 3/32" hole through the bottom of the existing bolt hole, into the exhaust area for the drainage to flow through. Yes, I know, you can’t get a clear shot at that with the drill. That’s what the aircraft drill bit is for. Eyeball-align the bit as close as you can with the bolt hole and drill right through the lower motor cover pan, enter the bolt hole, and carefully drill through the bottom of the hole till it breaks through inside. You should be able to tell when it hits "air" inside. Then STOP drilling. You don’t want to drill on through the next wall.

Screw the combo fitting into the bolt hole and attach the drain hose. You are done.

March 28, 2015 at 5:02 pm #12929I did something similar on a fellows motor, yet used 2 line pressure tank fittings and hose, and used the air line as a dump back into the tank for the pooled fuel/oil mixture. Still used the single line tank, just the double line fittings and line. For the dump line I plumbed a barb on the top of the tank which I attached to.

The owner of the motor didn’t want to see it dumped in the lake, and wanted me come up with an idea, and that’s all I could think of.

Only down fall of this would be if you didn’t run your tank out every now and then, and just always topped up, you could eventually get a pretty rich mixture, but other than that seemed to work well.

March 28, 2015 at 11:55 pm #12954Thanks Frank ,

I see. This is good information I will keep in mind. I just let go of a 68 18hp not long ago.March 29, 2015 at 12:28 am #12955Chris_P, any pictures of your plumbing job?

March 29, 2015 at 12:41 am #12956Not of that motor, but have a couple of Big Twins I have done in a similar manner downstairs. Ill post some pics tomorrow of them. I did the same thing, but ran a hose from the 302033 cover (after tapping in barb and plugging drain hole). This mod on the Big Twin is not so much for improved idle, as it was for pollution reduction. I installed a fuel pump on the Big Twin, but kept the double line fuel fitting on the motor. The second line returned the un burnt fuel/oil mix that was going to be going out the exhaust, and returned it to the fuel tank.

They don’t return much fuel/oil mix at WOT, but collect quite a bit at idle.

-

AuthorPosts

- You must be logged in to reply to this topic.