Home › Forum › Ask A Member › ?????? Question Johnson QD-16

- This topic has 39 replies, 15 voices, and was last updated 4 years, 1 month ago by

fleetwin.

-

AuthorPosts

-

May 25, 2019 at 10:56 am #176010

Maybe it was 1/8″ , it was a perfect fit. Just glad it’s pumping water right now. NOW……. next question it starts fine but will not idle. It’s smoking like crazy, burn your eyes type smoke. Mixed fuel at 24:1. I’m wondering about the throttle cam adjustment. When the cam follower is lined up with the mark on the brass cam the throttle is NOT opening yet. It’s probably 1/2″ past the mark before the throttle moves. If anyone has the service manual adjustment procedure, or knows if it’s on the site somewhere I’d appreciate it. I’ve adjusted the hi/low idle to recommended initial settings. FYI I can manually open throttle and it seems like it smooths out a lot. I know I’m rambling but any help is appreciated

Loosen the bolts on the underside of the cam and adjust until throttle butterfly just starts to open when the follower hits the mark on the cam.

May 25, 2019 at 3:10 pm #176017Ok I’ve laid the Johnson to the side for right now, before I get aggravated and lose interest all together. In earlier posts I’d mentioned that I have 8 or 9 engines total. (A mariner 30hp on my boat now , that runs perfect) anyway it seems every compression check I do is 50 lbs (give or take a few) I have a 5 hp Scott Atwater that I thought I’d look at. Out of all the ones that have read “low compression- 50 lbs, this one is the worst at about 30lbs top and bottom. But when I pulled this one before checking I assumed it was gonna be low , not a lot of resistance at all — noticeable. So I decided for the experience I’d start complete disassembly . There are no noticeable grooves in the cylinder wall or on piston . Doesn’t appear to have standard reed valves that I can see. The opposite side from reed valve (combustion chamber? Is really dirty /oily. Any way maybe new rings would restore compression on this one?? I’m trying to enclose some pics . I really really wanna get one of these engines actually usable type running in order to make this hobby enjoyable lol

It's a jungle out there.

-

This reply was modified 6 years, 1 month ago by

Mumbles.

Mumbles.

May 25, 2019 at 3:24 pm #176021I really don’t see anything wrong with those pictures. Or is it just me?

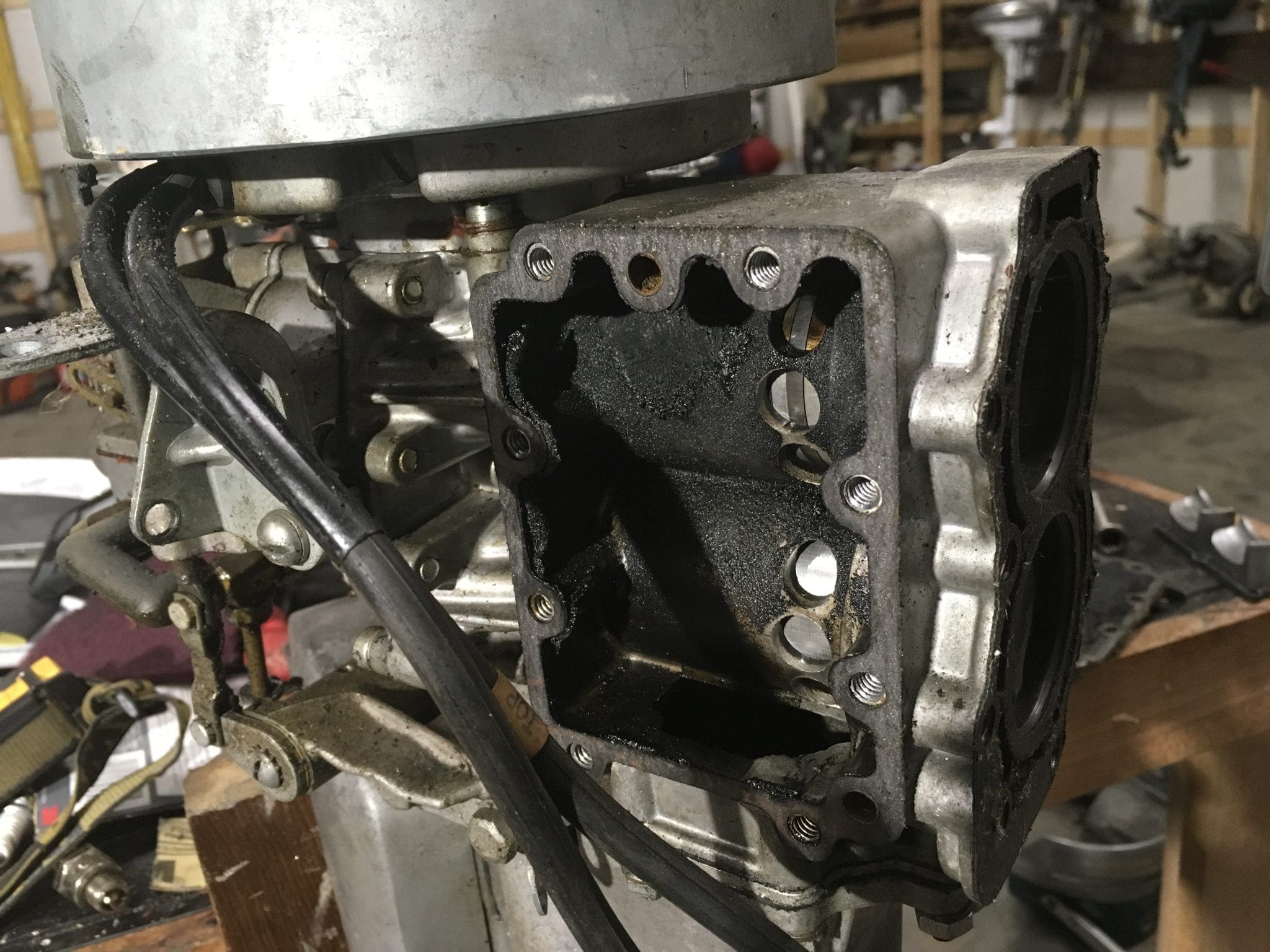

May 25, 2019 at 4:10 pm #176022I thought the reed was a metal plate with a “flap” like to allow air in during combustion. I’m assuming the aluminum piece in 2nd pic is a different style? And the first pic… is it normal for the oil/grease to build up in this area? Without knowing and checking the measurement of the cylinder I don’t know if the low compression is due to that or worn rings or combination of both. Due to oversized pistons being non existant I’m assuming the only way to get the compression up would be to replace the rings. Again not wanting or needing a “like new” engine just one I can put on my boat and putt around in. As I stated when I pull the rope it’s obvious that the compression is low. Im sure compression has to be “reasonable” for the engine to start and run

It's a jungle out there.

May 25, 2019 at 4:10 pm #176023I thought the reed was a metal plate with a “flap” like to allow air in during combustion. I’m assuming the aluminum piece in 2nd pic is a different style? And the first pic… is it normal for the oil/grease to build up in this area? Without knowing and checking the measurement of the cylinder I don’t know if the low compression is due to that or worn rings or combination of both. Due to oversized pistons being non existant I’m assuming the only way to get the compression up would be to replace the rings. Again not wanting or needing a “like new” engine just one I can put on my boat and putt around in. As I stated when I pull the rope it’s obvious that the compression is low. Im sure compression has to be “reasonable” for the engine to start and run

It's a jungle out there.

May 25, 2019 at 4:12 pm #176024Sounds like it’s time to try a different compression gauge!

Prepare to be boarded!

May 25, 2019 at 7:26 pm #176029Ok so I see my mistake on the reed valves, as their behind the carburetor. How would you know that they are sealing correctly? There was a lot of oil or really thick gas back behind the carb. On the compression gauge IDK I checked it on the QD-16 after it had ran a bit and it went from 50 up to 60. I know it’s a cheaper one but the one I saw at nappa wasn’t much different just a shorter hose but they wanted $80 for it. I’m a plumber by trade and we build our own test rigs for different systems we install and hardly ever is the gauge flat out bad. Like I say this engine , you can tell by the pull rope compression is weak. My question I guess is weak compression ALWAYS worn rings-piston or bore? Are there other common worn components to be on the look out for? 2- strokes are new to me. I’ve rebuilt chevy v-8’s and a Kohler k-241 mower engine which purrs like a cat. I just need pointers on where to start with these weak compression engines. Someone on here said the QD-16 at 60 was real low, so I’ve kinda quit on it cuz it’s running like crap and I feel like I’m spinning my wheels trying to get it to propel a boat and run consistent with the compression at 60. On the scot Atwater I’m gonna see if I can get the compression up BEFORE I do anything else.

It's a jungle out there.

May 25, 2019 at 7:40 pm #176030A bad head gasket could allow compression to leak between cylinders resulting in low readings. From the picture, it looks like your head gasket is OK but hard to tell from just a picture. Stuck rings will also result in low readings. Take a small screwdriver and push on the rings through the exhaust ports and see if the rings have some “spring” to them. If the rings are not stuck they should push in slightly then spring back when you release pressure on them. Again, hard to tell from just the pictures but your pistons and cylinders all look OK except the one piston ring visible in the picture, that ring looks like it might be partially stuck in its land (in the portion visible through the top exhaust port).

Edit – yes, in your first pic it is normal for carbon to have built up in the exhaust area especially with the older oils used back in those days. That can easily be cleaned up.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."May 25, 2019 at 9:28 pm #176049Thanks for the info bob. I’ll check the rings. I really enjoy the thought of bringing one of these 70 year old engines back to life but just not having any luck as of yet. Maybe I just need to paint em to look new and be happy with that.

It's a jungle out there.

May 25, 2019 at 11:07 pm #176052Each ring was springy on both sides (intake and exhaust) not a lot of push,but some. Would anybody happen to know the bore size and tolerance for it to be considered within spec? I’m thinking if the cylinder is really close then I can put new rings in and maybe it won’t be like new but have enough compression to run smooth once again for a little occasional use (after carb rebuild, check coils, clean or replace points and condenser and go thru lower unit.

It's a jungle out there.

-

This reply was modified 6 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.