Home › Forum › Ask A Member › RD-17 and RD-18 exhaust leg cracks

- This topic has 11 replies, 8 voices, and was last updated 5 years, 8 months ago by

olcah.

olcah.

-

AuthorPosts

-

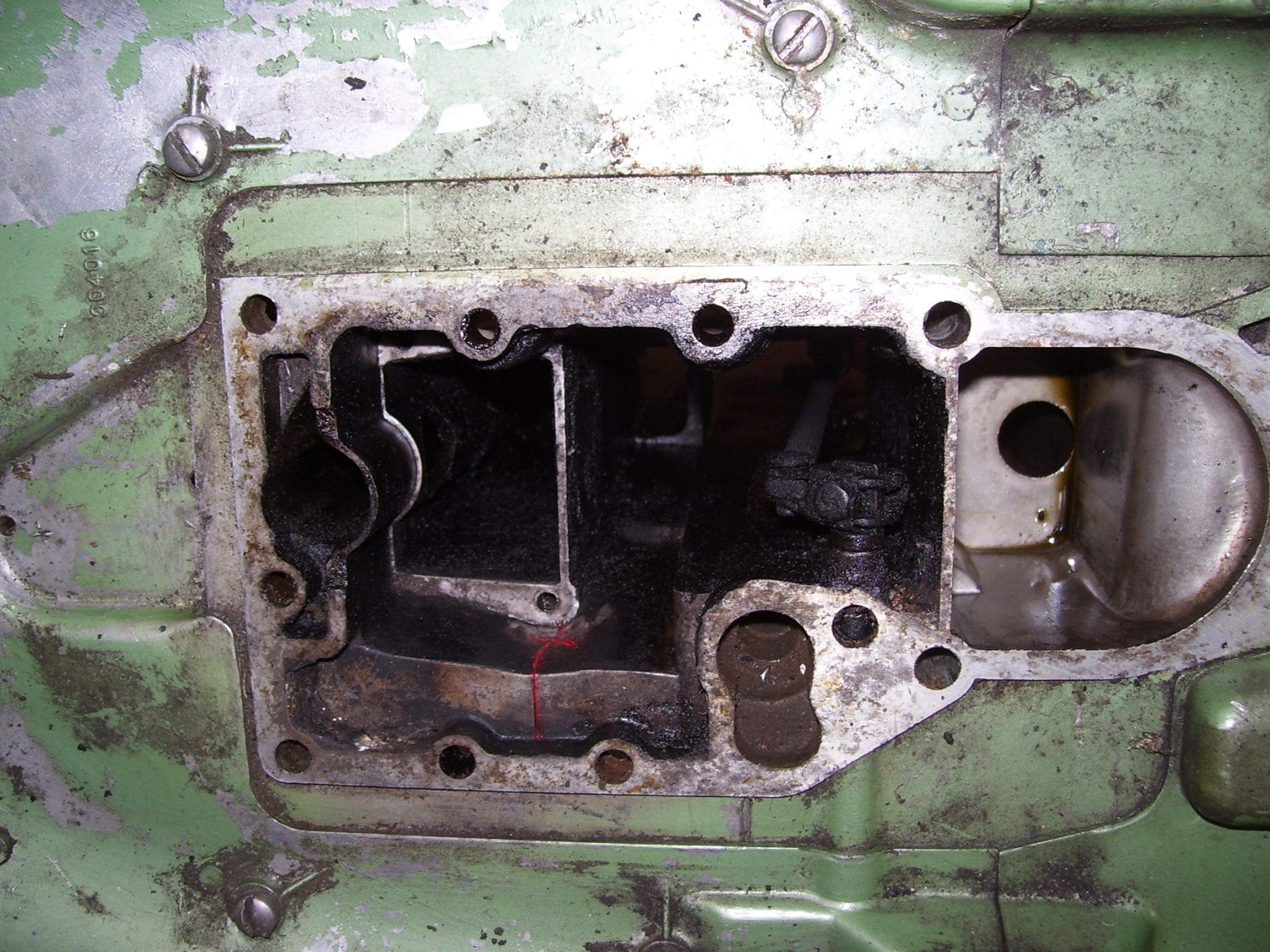

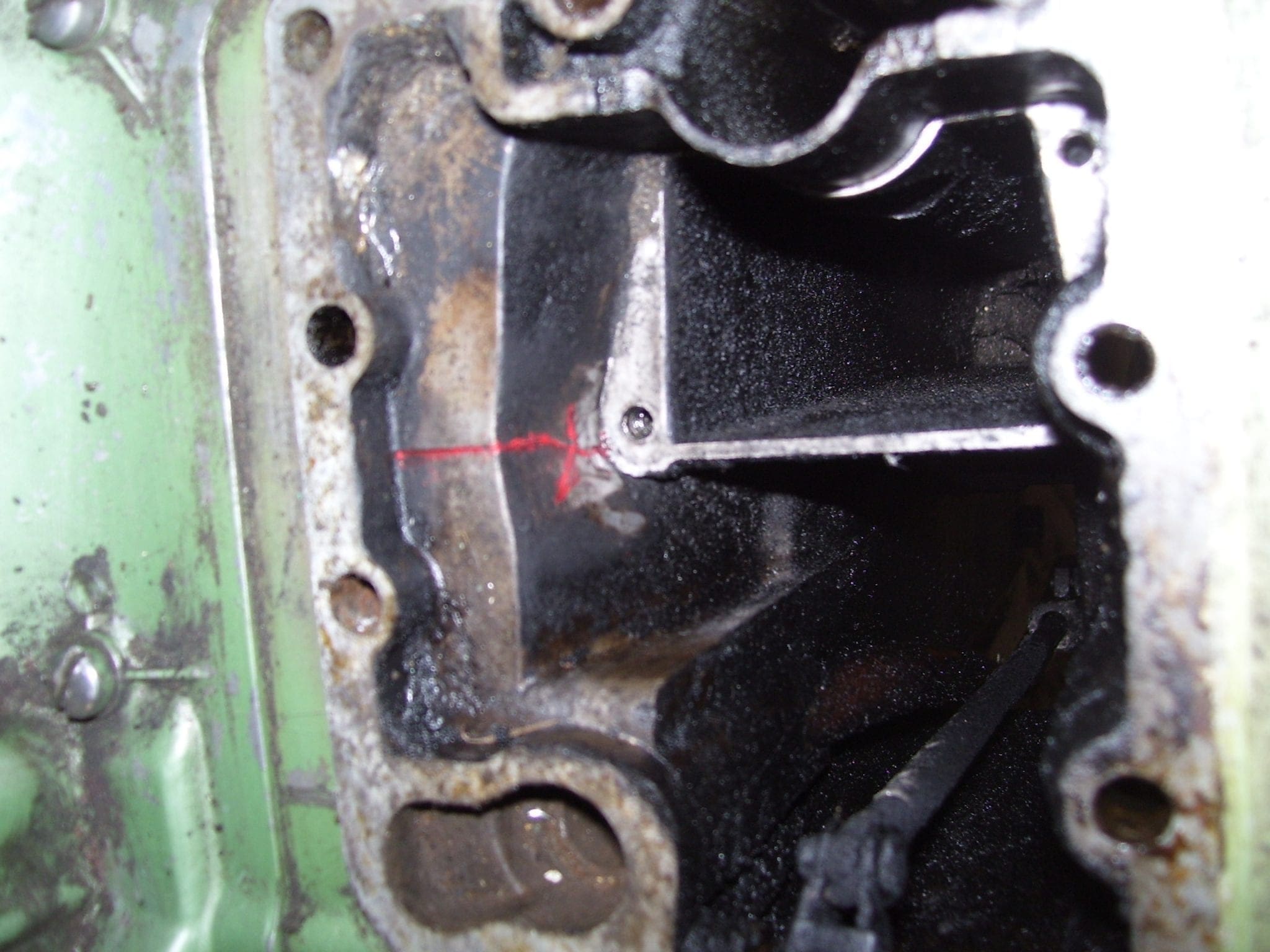

November 3, 2019 at 8:20 pm #186408

Looking at a 1955 25 HP Johnson RD-17 I noticed the cracking that I highlighted with a red pencil. I noticed crack in same location on the outside of the leg. Checked several 1956 RD-18 30 HP Johnsons and found the same crack in a couple of them only not as developed. I see this is a very thin section of the casting and expect these develop from cooling stresses in the casting or when the motor strikes something underwater. My guess is these are “no problem mate” type cracks but I am curious if others with more longer experience have noticed them or had any problems.

Thank you,-

This topic was modified 5 years, 8 months ago by

Mumbles.

Mumbles.

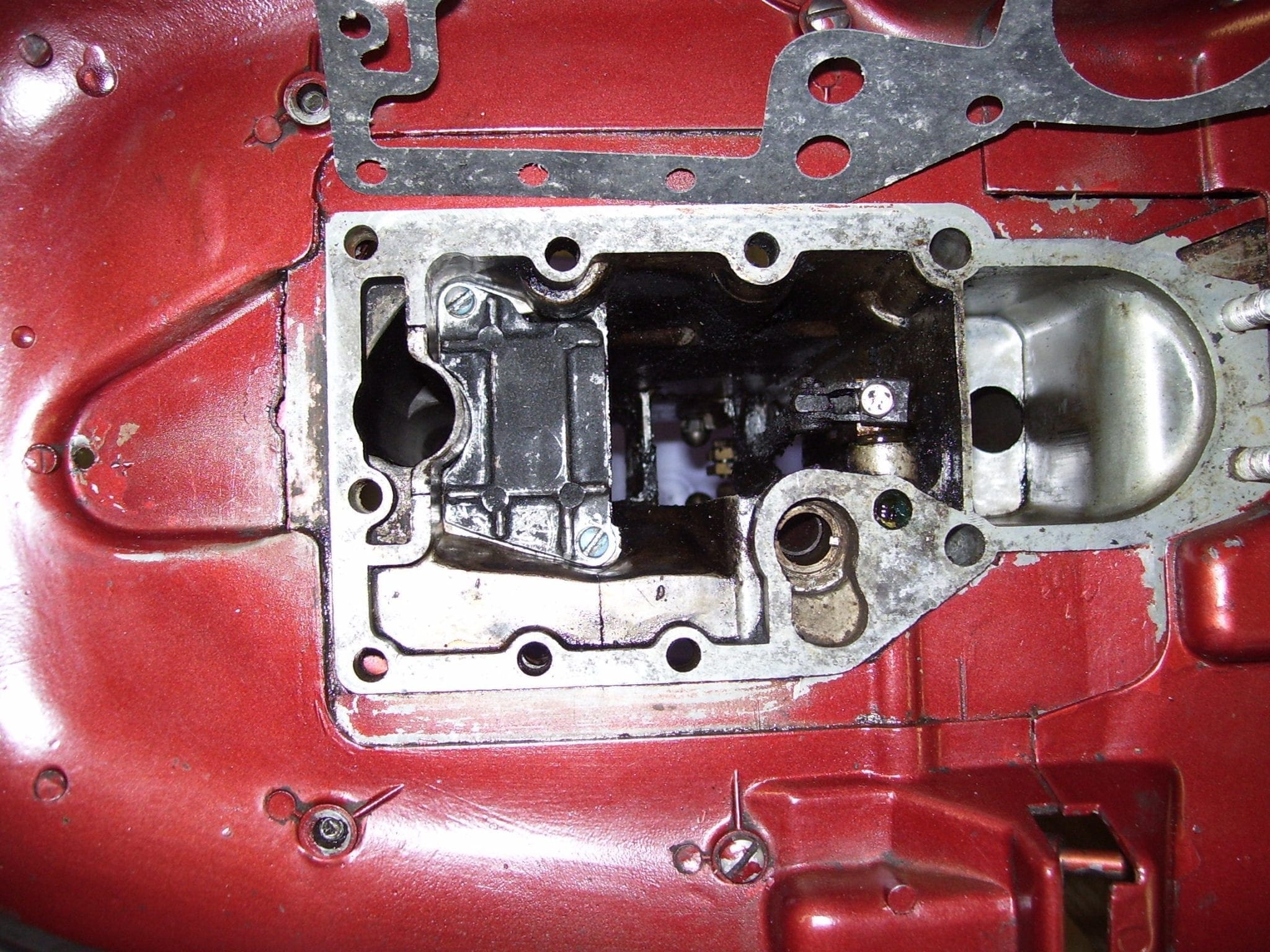

November 3, 2019 at 9:22 pm #186425For comparison I looked at some Ask a Member pages and found 3 images of RD-17s. All three are cracked in same location. 🙂

November 3, 2019 at 10:13 pm #186426Stress fractures from varying heat expansion rate is a plausible explanation. It never showed up in the factory one thousand hour test engines and I have never heard of any catastrophic failures because of it. There was a company in the mid ’50s that made and promoted a Water ski tow rope attachment that bolted to the narrow section of the Exhaust housing. These quickly developed cracks at that point in the housing which caused OMC to issue a warning that the use of this device would void the factories warrantee.

-

This reply was modified 5 years, 8 months ago by

garry-in-michigan.

garry-in-michigan.

November 4, 2019 at 6:49 am #186429November 4, 2019 at 9:15 am #186445Garry,

Thank you for your experience/take on this. Looks to me like most all of these motors have or will develop this crack and it is no problem. Outboardnut’s photo shows the same location as the others that I have seen, maybe not as developed because the motor has not been run as much. 🙂November 4, 2019 at 9:32 am #186446maybe you can bridge the crack on the inside surface with a small piece of aluminium plate by securing with 2 small bolts or have it welded if it is a big concern

Joining AOMCI has priviledges 🙂

November 4, 2019 at 10:24 am #186454I believe it is interesting but of no concern. The crack appears to be on nearly all of these motors for at least two model years. If it lead to problems I think people with long experience like Garry would know about it.

November 4, 2019 at 2:04 pm #186461Just seems like something that develops due to the strain of the fastener that is located right there. I wouldn’t worry about it either unless an exhaust leak develops or the crack spreads

November 4, 2019 at 4:40 pm #186469Once upon a time, many moons ago, there was a service bulletin concerning extra exhaust cooling. Don’t remember if it applied to this or not. It would take me forever to find it, if I even have it.

November 5, 2019 at 6:29 pm #186524Notice how the crack does not extend into the mating surface for the gasket. I’d not worry about it.

George

-

This topic was modified 5 years, 8 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.