Home › Forum › Ask A Member › Recharge Magnets on Fly Wheel

- This topic has 31 replies, 12 voices, and was last updated 4 years, 5 months ago by

Tubs.

Tubs.

-

AuthorPosts

-

December 17, 2018 at 11:18 am #160423December 17, 2018 at 4:58 pm #160474

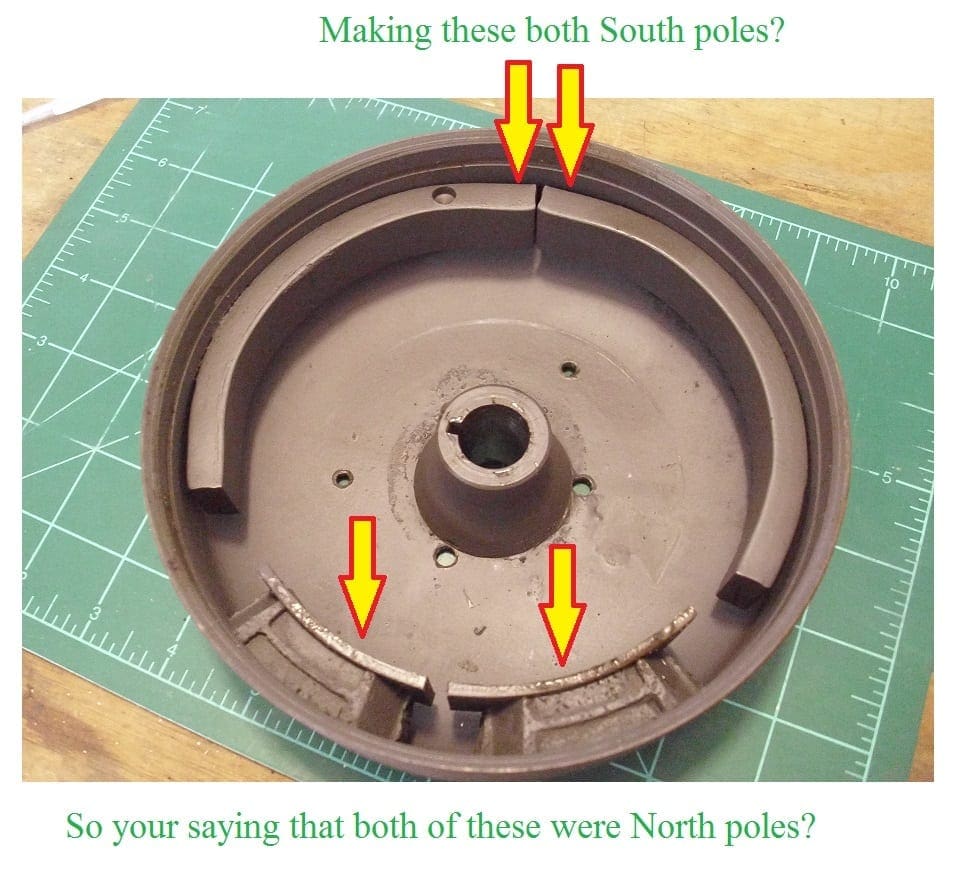

Yup, Tubs. Both of the magnets that your lower arrows point to were North Poles. Your upper arrows are simply pointing to the balance weights. Some of the Phelon flywheels only had one weight, but the magnets were the same as those in your photo. The Phelon magneto will work with the magnets charged either North and South, or South and North. They must be different. The sequence will determine whether the mag. produces a positive or negative spark. Negative is preferred. They both work as in the 4 cylinder mags used on Mercury’s 4 cylinder inline engines that had alternating positive and negative sparks. Cheers, R.T.

December 18, 2018 at 11:33 am #160624Oh, for Pete’s sake, here we go again…….repeating anecdotes, mythology and misinformation as if it was actual knowledge.

To quote Lord Kelvin:“I often say that when you can measure what you are speaking about,

and express it in numbers, you know something about it; but when you

cannot measure it, when you cannot express it in numbers, your knowledge

is of a meager and unsatisfactory kind.”Did ANY of the prior posts give actual MEASUREMENTS of magnetic field strength in Gauss (before and after the flywheel was “re-magnetized”?) Did anyone MEASURE the spark strength, or how fast the flywheel had to be spun to generate enough voltage for the spark to be generated (measured in RPM)? No.

The members of the Western Reserve Chapter of AOMCI are currently doing a FORMAL study of flywheel magnets, and the effectiveness of “re-magnetizing” flywheels. See the pictures (attached below):

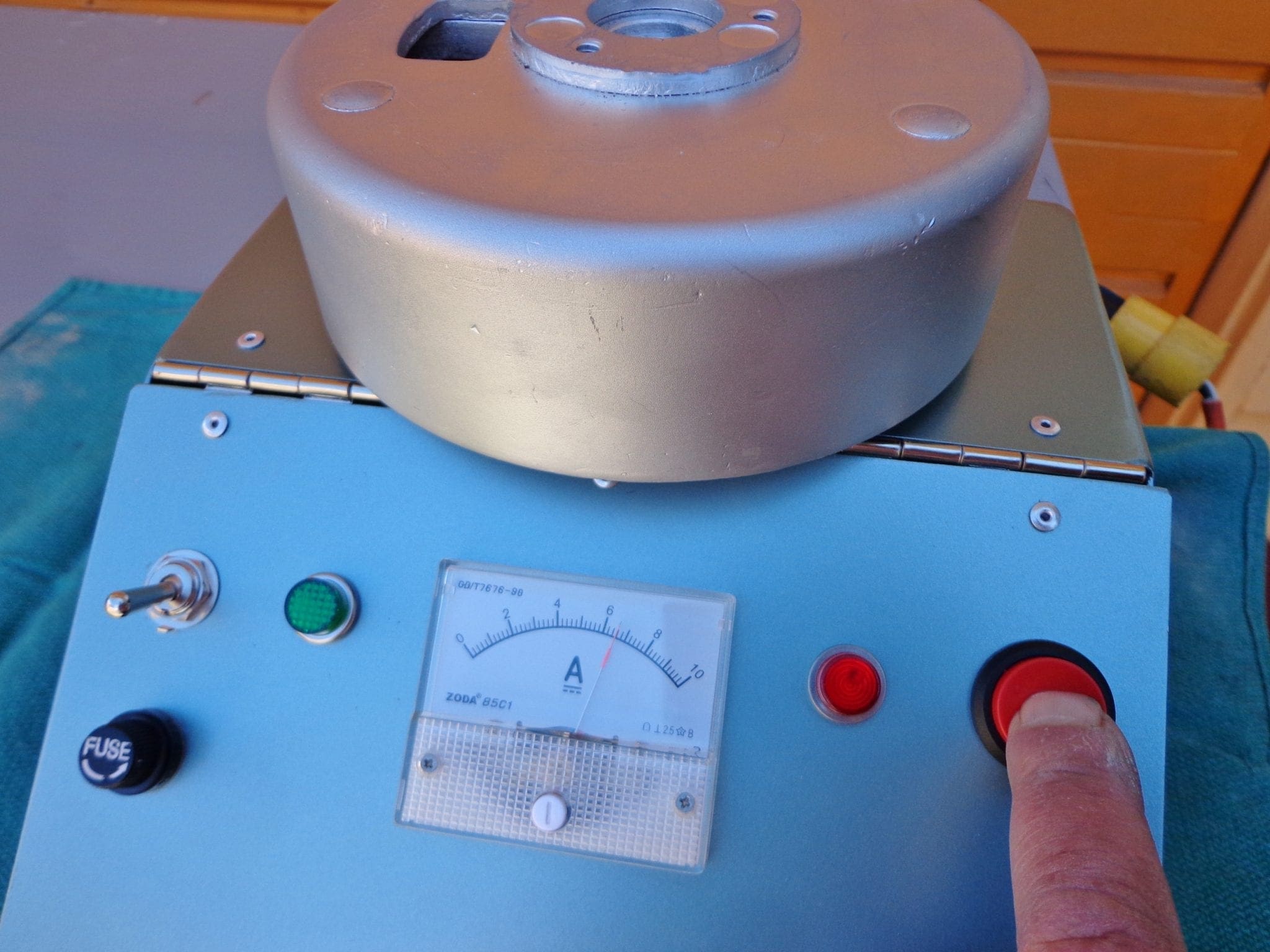

The first picture is of our test setup. We use a PRECISELY MEASURED spark gap, and then use a Optical Tachometer to measure the RPM of the engine precisely. We then use a variable speed drill to spin the flywheel, and we slow it down until the spark JUST BARELY WORKS, and record this as our “starting RPM”.

The second picture is of a “Tesla Meter”, which measures magnetic field strength in “milliTeslas” (multiply by 10 to get Gauss). Here, I am measuring a cheap magnet from the hardware store: the meter indicates NORTH, 556 gauss. We use this Tesla meter to measure the magnetic field strength of flywheel magnets BEFORE, and AFTER we re-magnetize the flywheel magnets. So, we know PRECISELY how much the magnetic field strength was increased (if any).

We then put the flywheel back on the outboard, and again spin the motor, to see what RPM is needed to get the spark to work, AFTER the magnets were re-magnetized, to see if spark can now be generated at a lower RPM. (Obviously, the lower you have to spin an outboard for the spark to be generated, the easier it will be to start that outboard motor.)

Note that we have MEASURED EVERYTHING at every step of the way, so we are attempting to generate KNOWLEDGE instead of guesses and assumptions.

So far, we have only run complete tests on 6 old outboards. While we can see some patterns emerging from this test data, only 6 test cases isn’t nearly enough to draw any conclusions. We would like to run these tests on 10 or 20 (or more!) outboards, before we will draw any conclusions, and publish our test results. Hopefully, this will end all the misinformation floating around out there.

We would like assistance with this test study. If anyone has an outboard that you would like the magnets re-done, just bring it to any of the weekly Western Reserve AOMCI club meetings, and we’ll be glad to include you in our study. NO CHARGE, of course!

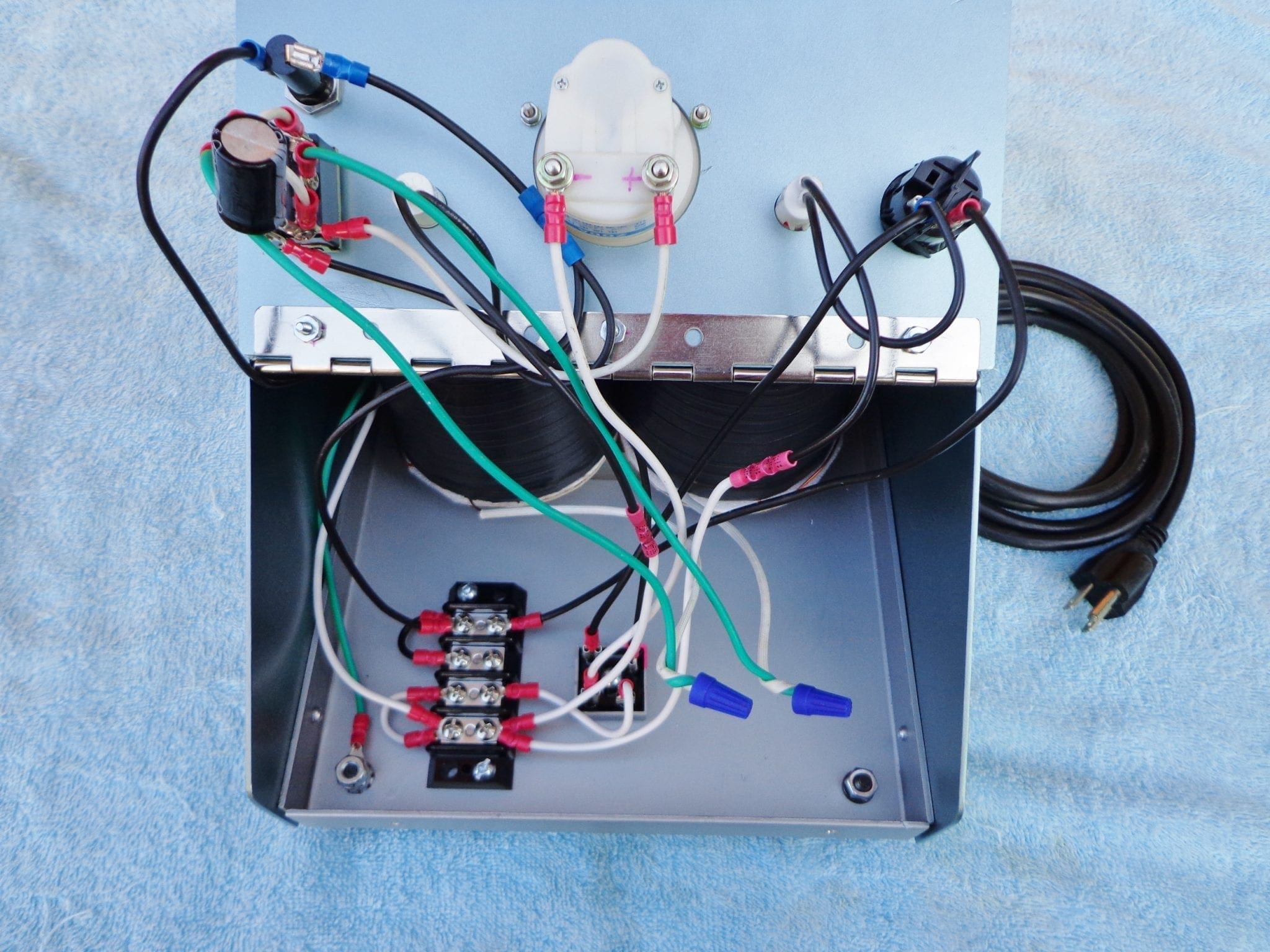

I’d also like to ask if anyone has a complete copy of any documentation for those Stevens magnetizers. (See the last picture, attached below). Our magnetizer was completely rebuilt, switches cleaned, rust removed, repainted, and the top re-surfaced with polycarbonate to prevent scratching up any paint during normal use. But, we haven’t been able to locate complete documentation for it. If anyone has a copy of the user’s manual for these Stevens units (as raw pictures or as a PDF file), please let us know. Thanks!

The one piece of knowledge I can state for certain is that YOU CANNOT DAMAGE magnets in a flywheel. You can use a magnetizer incorrectly and screw up the magnets’s strength, but you can always then re-do the procedure correctly and restore the magnets to full strength again if you wish. Steel, Alnico, ….makes no difference, the Stevens unit can handle them both. We haven’t come across any outboards with Samarium Cobalt or Neodymium Iron Boron Magnets…(does anyone know of any?) And, we also don’t know the history; does anyone know WHEN outboard manufacturers switched from steel to Alnico magnets in flywheel construction?

–Bill Mohat / AOMCI, Western Reserve Chapter

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

December 18, 2018 at 11:36 am #160627Gaussmeter picture, attached below.

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

December 18, 2018 at 2:55 pm #160638This is super. Data gathering. Have you established a consatnt distance from the magnet’s center to measure the strength from? Most flywheel magnetos have their magnets closely spaced, and adjacent magnets can affect the magnetic field of one another if measured at too great a distance. A thickness of index card might be a good constant, and it would prevent the measurement probe from having intimate contact with the magnet pole. Does your gaussmeter suggest a standard distance? I’m thrilled to read of your quest. My ex-racing partner, Charlie Erdman worked for GE Medical systems, and the lab he ran had all of the magnet charging equipment we could ever wish for. He recharged the aluminum Bendix-Scintilla rotors with the polarity that produced the negative sparks that we desired. When we set the points at .009″ they consistantly outperformed the Phelon mags, with higher output voltage, faster time rise, and at nearly 1000 rpms higher crankshaft speeds. Charlie’s magnet charging equipment employed a great lot of capacitors that once charged, were discharged thru the coils of the charging units. Several thousand amps were said to have been released thru the coils for an instant, and Charlie told us that it created an outlandish bang when the button was pushed. My Stevens unit seems to require about 3 seconds of on time to fully charge the magnets. It’s way kool what you’re doing. Thanks from all of us. Knowledge is power. Cheers. R.T.

December 18, 2018 at 5:06 pm #160655Very interesting research you’ve got going on Bill.

I wonder if Nikola Tesla went thru the same experiments?Prepare to be boarded!

December 19, 2018 at 4:14 pm #160740foot_doctor:

The “Stevens Magnetizers” that the outboard guys use run off of 120VAC, full-wave rectified. They can generate maybe 8,000 gauss or so, which is OK for Steel and Alnico magnets……but are not strong enough to magnetize Samarium Cobalt or Neodymium magnets……for those, you have to generate magnetic field strengths on the order of 20,000 gauss or more.

The kind of magnetizer you are talking about (a capacitor bank discharger) will charge a huge bank of capacitors with up to 3,000 or 4,000 volts, and then dump that through the charging coil in just a few milliseconds…….creating 30,000+ peak gauss. Do NOT wear a watch in the room where one of those units is running! Keep your smartphone a BIG distance away as well…..or you’ll have to buy a new one.

See this video: (and note that they are charging a HUGE bank of capacitors up to 3,500 volts before doing the ‘charging’.

Also note that the actual charging time is just the duration of that “thump” sound that you hear. )See: https://www.youtube.com/watch?v=PVIAZmrQJDU&index=16&list=PLG3u0gcV6DRNgwaPAt-UzL86h6qOawmf7

HOWEVER……… it doesn’t matter how much power you use to “charge” a magnet; the material it’s made of determines how much of a magnetic field it can hold. Steel, maybe 2000 gauss; Alnico up to 6,000 gauss…..and that’s it. For magnets made of these two materials, “charging them” with a huge capacitor-discharge unit will cause them to have NO GREATER STRENGTH than charging them with that old Stevens unit…………..the material itself can’t hold any greater “charge”, no matter what the “charging strength” it was exposed to. Unless you re-machined the flywheels and installed Cobalt or Neodymium magnets into the flywheels, the expensive capacitive-discharge magnetizer you were using was just a waste of money and time. (If you had a gaussmeter and measured your flywheels when charged with a Stevens unit, compared to that monster capacitor-discharge unit, you would be able to prove this for yourself. Charge it with either magnetizer, and you’ll get the same field strength when you are done…….the magnetic characteristics of the raw materials creates this physical limit.)

So far in my testing, I haven’t found ANY older motors with Cobalt or Neodymium magnets; all that I’ve seen so far have been either raw steel (1920s and 1930s) or Alnico (1940s and later). Now, I suspect some of the VERY NEW outboards (in particular, the smaller 4-stroke fuel-injected units that do NOT NEED A BATTERY TO RUN……..I’ll bet that those units are using Cobalt or Neodymium

magnets, as they have to generate a LOT of energy on each revolution of the crankshaft……….but honestly, I haven’t been able to verify this yet. Maybe some other reader knows for sure about this?)As for the “charging time”……it takes microseconds for the magnetic material to take a “charge”, when exposed to a high enough external field. This is true not just of that expensive capacitor-discharge unit, but of the Stevens unit also. HOWEVER……unlike the small magnets shown in the video (referenced above), the old antique outboards had HUGE magnets, and sometimes VERY LARGE pole pieces. Rotating the flywheel a few degrees either way, and repeating the “charging” cycle several times, allows you to expose much more of the magnet material to the charging field, and DOES create a larger, final “charge” on the magnet structure when you are done. (Remember the old magnetic tape audio recorders? The tape accepted the audio information and recorded it as magnetic charges in THOUSANDTHS of a second………..the same is true for the magnets in your flywheels. Physics is physics, after all.)

As for how we are measuring the fields; my gaussmeter has a small, hand-held probe the size of a small pencil, with a hall-effect sensor embedded inside it. We are actually making contact with the magnets when we take measurements. Using a business card or some other “spacer” doesn’t really change the field any, over that short of a distance. We did, however, discover that the CENTER of the pole pieces typically has 1/4 to 1/10 of the field strength that you will measure at the EDGES of the pole pieces……and it’s VERY HARD to measure in the exact same location, short of using a “magic marker”, and marking on the poles exactly where your measurements were taken.

We really are not interested in laboratory-grade measurements; what we are interested in is the RELATIVE CHANGE in field strength before, and after, we “charge” the magnets…..and what effect it has. Did the magnetic strength increase by 25%? 50%? Did it DOUBLE? In each of these cases, could the magneto create spark at 25% LOWER R.P.M.? 50% lower? 1/2 as much? Is there any correlation between change in magnetic field strength, and the RPM at which spark can be generated? (So far, there’s a strong correlation between the two, but it’s NOT LINEAR…..and depends greatly on the physical design of the pole pieces, etc.)

About half of the outboards we tested so far showed either no, or very little change. About 30% lowered their starting RPM by 25%, and about 20% of the outboards lowered their starting RPM by HALF, making them MUCH easier to start than before.

There does seem to be a pattern emerging from our data, as to which generations of outboards are improved the most.

The 1920s vintage units typically had MASSIVE magnet structures……FAR larger than they needed. Even though they used low-grade steel magnets, most still have 75% of their charge, and most can generate spark at way under 100 RPM, even without being “recharged”. However, in the 1930s and 1940s, manufacturers started to use much smaller magnets and spark coils……and starting RPMs were around 200 to 300 RPM or so. For outboards in those time periods, it didn’t take much fading of the magnets to get you up to 300 to 500 RPM minimum (or worse) to generate a spark, making some of these outboards very difficult to start, and they just would not idle down unless they magnets were “re-charged” up to full strength.AGAIN (disclaimer here)…..we have only tested 10 outboards so far. I’d like at least another 10 to test before I’ll stand by those tentative conclusions, and actually publish them as “fact”. But, I’m having troubles locating volunteers to haul motors up for us to test. Actual testing only takes about 15 to 30 minutes. Anyone interested in participating?

–wmohat

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

December 19, 2018 at 4:18 pm #160741foot_doctor:

The “Stevens Magnetizers” that the outboard guys use run off of 120VAC, full-wave rectified. They can generate maybe 8,000 gauss or so, which is OK for Steel and Alnico magnets……but are not strong enough to magnetize Samarium Cobalt or Neodymium magnets……for those, you have to generate magnetic field strengths on the order of 20,000 gauss or more.

The kind of magnetizer you are talking about (a capacitor bank discharger) will charge a huge bank of capacitors with up to 3,000 or 4,000 volts, and then dump that through the charging coil in just a few milliseconds…….creating 30,000+ peak gauss. Do NOT wear a watch in the room where one of those units is running! Keep your smartphone a BIG distance away as well…..or you’ll have to buy a new one.

See this video: (and note that they are charging a HUGE bank of capacitors up to 3,500 volts before doing the ‘charging’.

Also note that the actual charging time is just the duration of that “thump” sound that you hear. )See: https://www.youtube.com/watch?v=PVIAZmrQJDU&index=16&list=PLG3u0gcV6DRNgwaPAt-UzL86h6qOawmf7

HOWEVER……… it doesn’t matter how much power you use to “charge” a magnet; the material it’s made of determines how much of a magnetic field it can hold. Steel, maybe 2000 gauss; Alnico up to 6,000 gauss…..and that’s it. For magnets made of these two materials, “charging them” with a huge capacitor-discharge unit will cause them to have NO GREATER STRENGTH than charging them with that old Stevens unit…………..the material itself can’t hold any greater “charge”, no matter what the “charging strength” it was exposed to. Unless you re-machined the flywheels and installed Cobalt or Neodymium magnets into the flywheels, the expensive capacitive-discharge magnetizer you were using was just a waste of money and time. (If you had a gaussmeter and measured your flywheels when charged with a Stevens unit, compared to that monster capacitor-discharge unit, you would be able to prove this for yourself. Charge it with either magnetizer, and you’ll get the same field strength when you are done…….the magnetic characteristics of the raw materials creates this physical limit.)

So far in my testing, I haven’t found ANY older motors with Cobalt or Neodymium magnets; all that I’ve seen so far have been either raw steel (1920s and 1930s) or Alnico (1940s and later). Now, I suspect some of the VERY NEW outboards (in particular, the smaller 4-stroke fuel-injected units that do NOT NEED A BATTERY TO RUN……..I’ll bet that those units are using Cobalt or Neodymium

magnets, as they have to generate a LOT of energy on each revolution of the crankshaft……….but honestly, I haven’t been able to verify this yet. Maybe some other reader knows for sure about this?)As for the “charging time”……it takes microseconds for the magnetic material to take a “charge”, when exposed to a high enough external field. This is true not just of that expensive capacitor-discharge unit, but of the Stevens unit also. HOWEVER……unlike the small magnets shown in the video (referenced above), the old antique outboards had HUGE magnets, and sometimes VERY LARGE pole pieces. Rotating the flywheel a few degrees either way, and repeating the “charging” cycle several times, allows you to expose much more of the magnet material to the charging field, and DOES create a larger, final “charge” on the magnet structure when you are done. (Remember the old magnetic tape audio recorders? The tape accepted the audio information and recorded it as magnetic charges in THOUSANDTHS of a second………..the same is true for the magnets in your flywheels. Physics is physics, after all.)

As for how we are measuring the fields; my gaussmeter has a small, hand-held probe the size of a small pencil, with a hall-effect sensor embedded inside it. We are actually making contact with the magnets when we take measurements. Using a business card or some other “spacer” doesn’t really change the field any, over that short of a distance. We did, however, discover that the CENTER of the pole pieces typically has 1/4 to 1/10 of the field strength that you will measure at the EDGES of the pole pieces……and it’s VERY HARD to measure in the exact same location, short of using a “magic marker”, and marking on the poles exactly where your measurements were taken.

We really are not interested in laboratory-grade measurements; what we are interested in is the RELATIVE CHANGE in field strength before, and after, we “charge” the magnets…..and what effect it has. Did the magnetic strength increase by 25%? 50%? Did it DOUBLE? In each of these cases, could the magneto create spark at 25% LOWER R.P.M.? 50% lower? 1/2 as much? Is there any correlation between change in magnetic field strength, and the RPM at which spark can be generated? (So far, there’s a strong correlation between the two, but it’s NOT LINEAR…..and depends greatly on the physical design of the pole pieces, etc.)

About half of the outboards we tested so far showed either no, or very little change. About 30% lowered their starting RPM by 25%, and about 20% of the outboards lowered their starting RPM by HALF, making them MUCH easier to start than before.

There does seem to be a pattern emerging from our data, as to which generations of outboards are improved the most.

The 1920s vintage units typically had MASSIVE magnet structures……FAR larger than they needed. Even though they used low-grade steel magnets, most still have 75% of their charge, and most can generate spark at way under 100 RPM, even without being “recharged”. However, in the 1930s and 1940s, manufacturers started to use much smaller magnets and spark coils……and starting RPMs were around 200 to 300 RPM or so. For outboards in those time periods, it didn’t take much fading of the magnets to get you up to 300 to 500 RPM minimum (or worse) to generate a spark, making some of these outboards very difficult to start, and they just would not idle down unless they magnets were “re-charged” up to full strength.AGAIN (disclaimer here)…..we have only tested 10 outboards so far. I’d like at least another 10 to test before I’ll stand by those tentative conclusions, and actually publish them as “fact”. But, I’m having troubles locating volunteers to haul motors up for us to test. Actual testing only takes about 15 to 30 minutes. Anyone interested in participating?

–wmohat

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

December 19, 2018 at 4:30 pm #160743Buccaneer:

Nikola Tesla was interested in high frequency, high-voltage transformers. During his lifetime, there WAS NO WAY to directly measure magnetic fields ….saturable reactors, hall-effect devices and other field sensors weren’t developed until many decades later…… (how Maxwell derived his equations in the 1850s is a complete mystery to me!) I don’t think Tesla was directly interested in magnets or magnetic fields, short of the coupling fields used in transformer windings. The people that designed power generation equipment at that time in history – (Edison, Westinghouse, etc)…..those guys were interested in the magnetic strength of the excitation fields in their generators, but they had no way to directly measure it, unless you count a block of steel and a spring scale. It’s amazing how the science pioneers were able to make the discoveries that they did, with the primitive tools of the time.

–wmohat

***********************************************************************

Bill Mohat MS/CIS, BSEET, CCNA"You can avoid reality, but you cannot avoid the consequences of avoiding reality." --Ayn Rand **********************************************

December 20, 2018 at 12:00 pm #160779Very interesting read and I’m a firm believer in the benefits of recharging a flywheels magnets after having done it myself and seen the results. A Johnson 300 I have came back to life from a weak spark-no start situation to a sweet running motor after recharging the magnets. This was done with a home built charger since I couldn’t find a Stevens charger anywhere.

Here’s a video of a group of outboarders getting charged up.

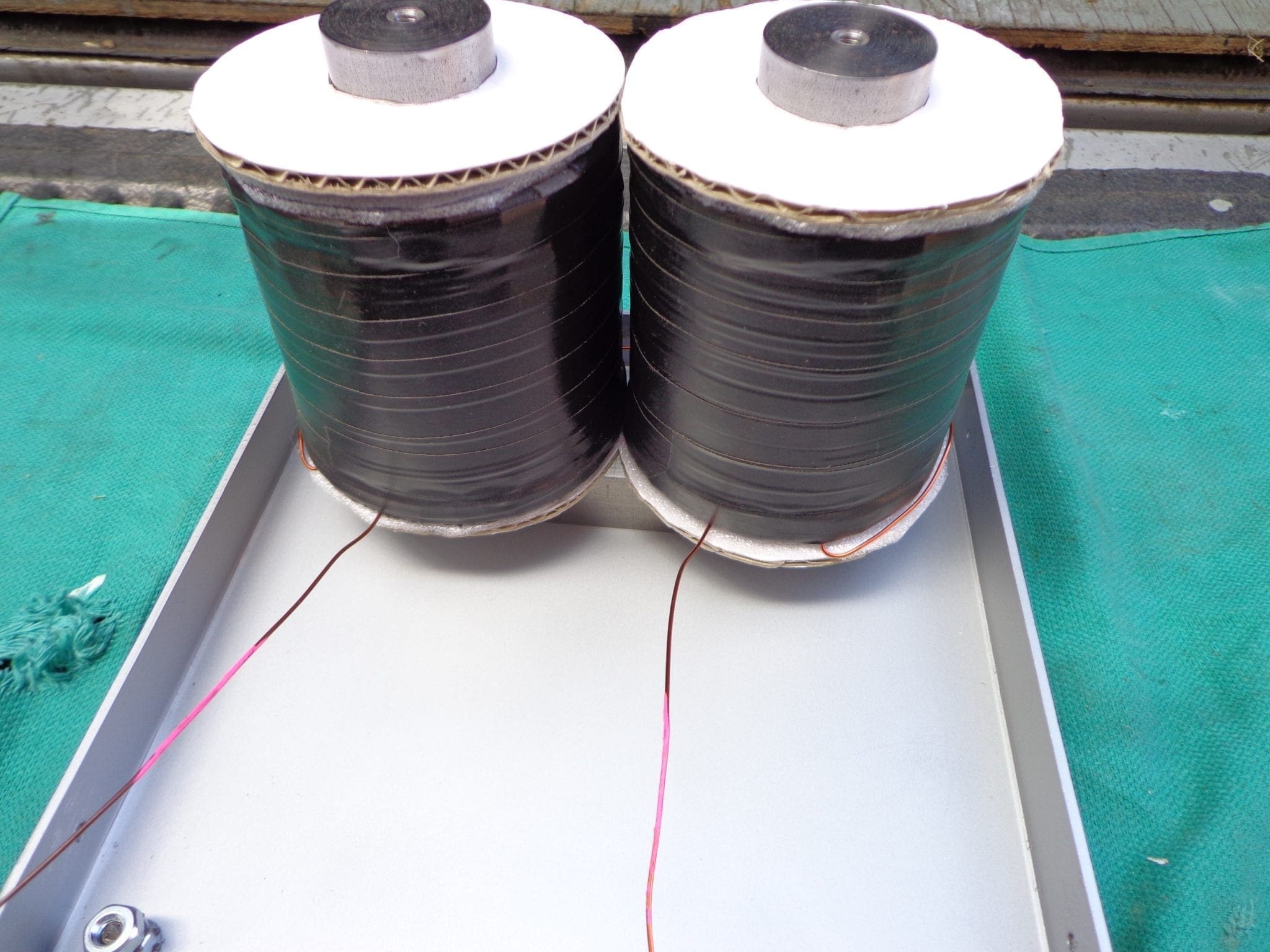

Here’s some photos of a Stevens charger and a charger I built which is kind of similar to it.

-

AuthorPosts

- You must be logged in to reply to this topic.