Home › Forum › Ask A Member › Recoil Question – 1991 15 HP Johnson

- This topic has 4 replies, 3 voices, and was last updated 4 years, 10 months ago by

outbdnut2.

-

AuthorPosts

-

June 23, 2019 at 12:21 pm #177863

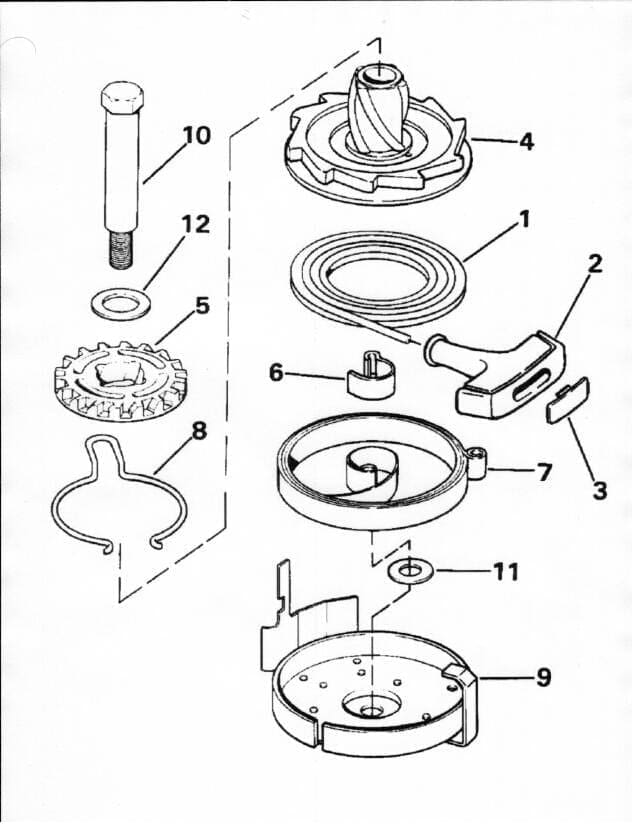

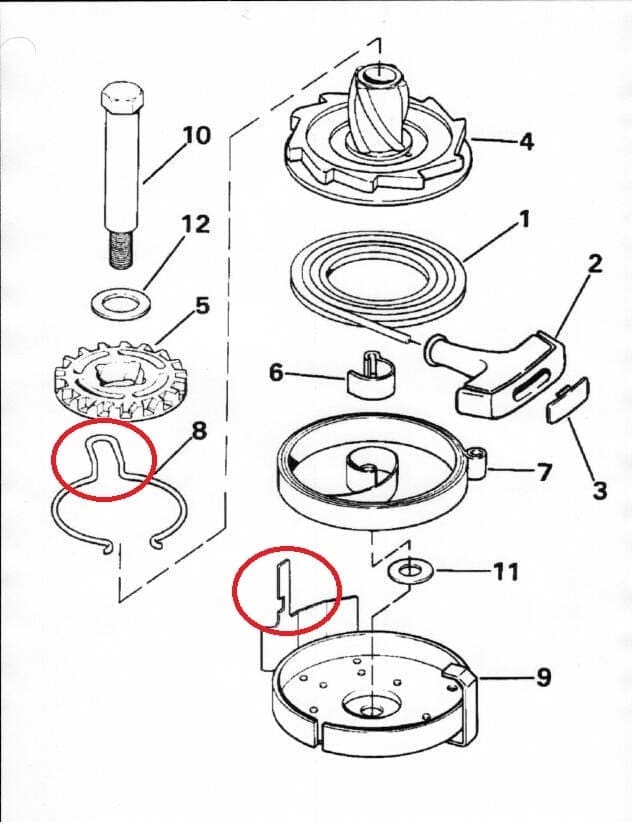

OK – so this motor isn’t that old – well it’s almost 30 years now I guess. When I pull the rope, the engagement gear does not rise to the flywheel unless I put some tension on it with my finger. It appears that

the wire pinion spring, part 8, has to put some friction on the pinion, part 5 to allow it to rise up to the flywheel. Is that the way it works? and is the fix to clean the #8 spring and the mating groove on the #5 pinion? or do I need a new pinion? I took the spring off and tried bending it to give more tension. While I had it off, I put a small screwdriver in a rag and tried to clean greasy residue out of the spring-groove on the underside of #5 pinion, but it didn’t help. The pinion is not binding up on the #4 part that it has to spiral up on. The protruding part of the #8 spring is properly positioned on the chunk of metal sticking up form part #9That spring groove under part 5 is not super clean yet.

Hope the parts diagram comes through below.

DaveJune 23, 2019 at 12:48 pm #177869You have the theory of operation correct so it should work. All parts go together dry, except for the main spring, #7 and the cup, #9, which should be lightly greased. A common mistake is not getting the hook on spring #8 placed correctly over the vertical tab on the cup, #9.

As the rope is pulled and the starter pulley, #4, starts to turn, the tension of spring #8 holds the pinion gear, #5, in place and it starts to climb the threads on the starter pulley. If the pinion gear spins with the starter pulley instead of climbing the threads, I’d say there isn’t enough tension on the #8 spring.

What shape are both threads in? Any nicks or rough surfaces causing the parts to bind?

June 23, 2019 at 2:15 pm #177873I haven’t taken the assembly apart yet to see if there are nicks or rough surfaces, but, based on what you said, I think it just needs a good cleaning, because very little finger pressure on the part causes it to rise up fine, and once it starts rising, it easily goes up all the way without my finger on it. I was getting a lot of grease on the rag when I tried to do a quickie cleaning out of the groove the spring goes in with a rag over a small screwdriver blade. I’ll take the recoil assembly out and clean those parts good. I have five of these motors with mega-hours on them from a failed resort, so I’ve had the assemblies out before, dealing with broken rewind springs, ropes, and related issues, so I know how they come apart. Also have removed the recoil assemblies, putting a nut under them to hold together, to get at carburetor mounting nut.

Once it’s clean, would it be a good idea to slightly rough-up the spring-groove in art #5 with some light sandpaper?

Thx for the info!

DaveJune 24, 2019 at 7:16 pm #177917Mumble’s advice is spot on, and it sounds like you have it assembled correctly. It is so important that the helix and gear groove where the friction spring rides is super clean and dry. You mentioned that you removed the friction spring and “tightened it up a bit”….This should have done the trick if everything else is OK. Did the friction spring look worn? The next time you pull the gear off, try spinning the friction spring on the gear to see how easy/hard it is to move on the gear…Needless to say, it should not move freely in the gear groove. I would not try to rough up the gear groove, that will probably just ruin it….I suppose it is possible that the gear groove is excessively worn, it is only plastic, but I have never seen that condition…

Again, try spinning the friction spring in the gear groove once it is off the starter….If it seems loose, then the spring is worn/loose, or perhaps the groove in the gear is worn…You mentioned these engines were used commercially, so anything is possible…June 27, 2019 at 5:16 pm #178073When I tried to tighten the spring, I don’t think I bent it far enough to make any difference. I finally got around to taking the assembly apart and cleaning/degreasing the groove where the friction spring rides by soaking the part in gasoline. It works perfect now. The way that works makes me wonder how someone came up with that idea for the design?

Thanks for all the info!

Dave -

AuthorPosts

- You must be logged in to reply to this topic.