Home › Forum › Ask A Member › Removing Broken Tank Filters From OMC Three Horse Motors

- This topic has 9 replies, 9 voices, and was last updated 5 years, 4 months ago by

crosbyman.

-

AuthorPosts

-

February 23, 2020 at 9:08 pm #195748

All too often the sintered filter/screen attached to the fuel shutoff tap breaks off while trying to remove the tap from the tank and it can be a challenge to get it out in one piece. So, instead of driving it into the tank and fishing it out thru the filler opening, I thread it internally and draw it back out the way it went in.

I can’t remember what size tap I used but it might have been a 5/16 coarse. Whatever size will cut a thread inside the filter will work.

Once the threads are cut, a matching bolt, nut, and washer are screwed into the filter and then the nut is ran down to draw the filter out of the tank.

Now the filter and the other parts can be cleaned up and the filter can be epoxied back onto the tap for reuse. This method works slick with no muss or fuss.

February 23, 2020 at 10:43 pm #195769If I ever come across that type of sintered filter, now I know what to do!

Thanks.Prepare to be boarded!

February 24, 2020 at 5:35 am #195773That’s a great idea, Mumbles! That happens to me pretty much every single time. So, once you get it out, it looks like you reuse it? Might as well explain your cleaning method and re-solder techniques, too….please?

Long live American manufacturing!

February 24, 2020 at 8:30 am #195779I’ve tried cleaning them by blowing carb cleaner through from the inside, but flow through the cleaned filter is never as good as flow through a new filter.

February 24, 2020 at 9:38 am #195786Neat trick Mumbles!

February 24, 2020 at 11:15 am #195790I have great luck using air conditioning evaporator coil cleaner. Comes in a qt bottle & green in color. A few oz a few times & it works well. At least with Merc sintered filters that are NLA.

February 24, 2020 at 11:24 am #195791What type of epoxy do you use that resists gas/oil?

February 24, 2020 at 1:45 pm #195796Since the area that is being epoxied isn’t technically “submerged” in fuel my guess is Marine-Tex or JB Weld would work. The couple I’ve come across over the years that were separated like that almost looked as though an 847 type adhesive was used on them originally.

February 27, 2020 at 4:10 pm #195987Don,

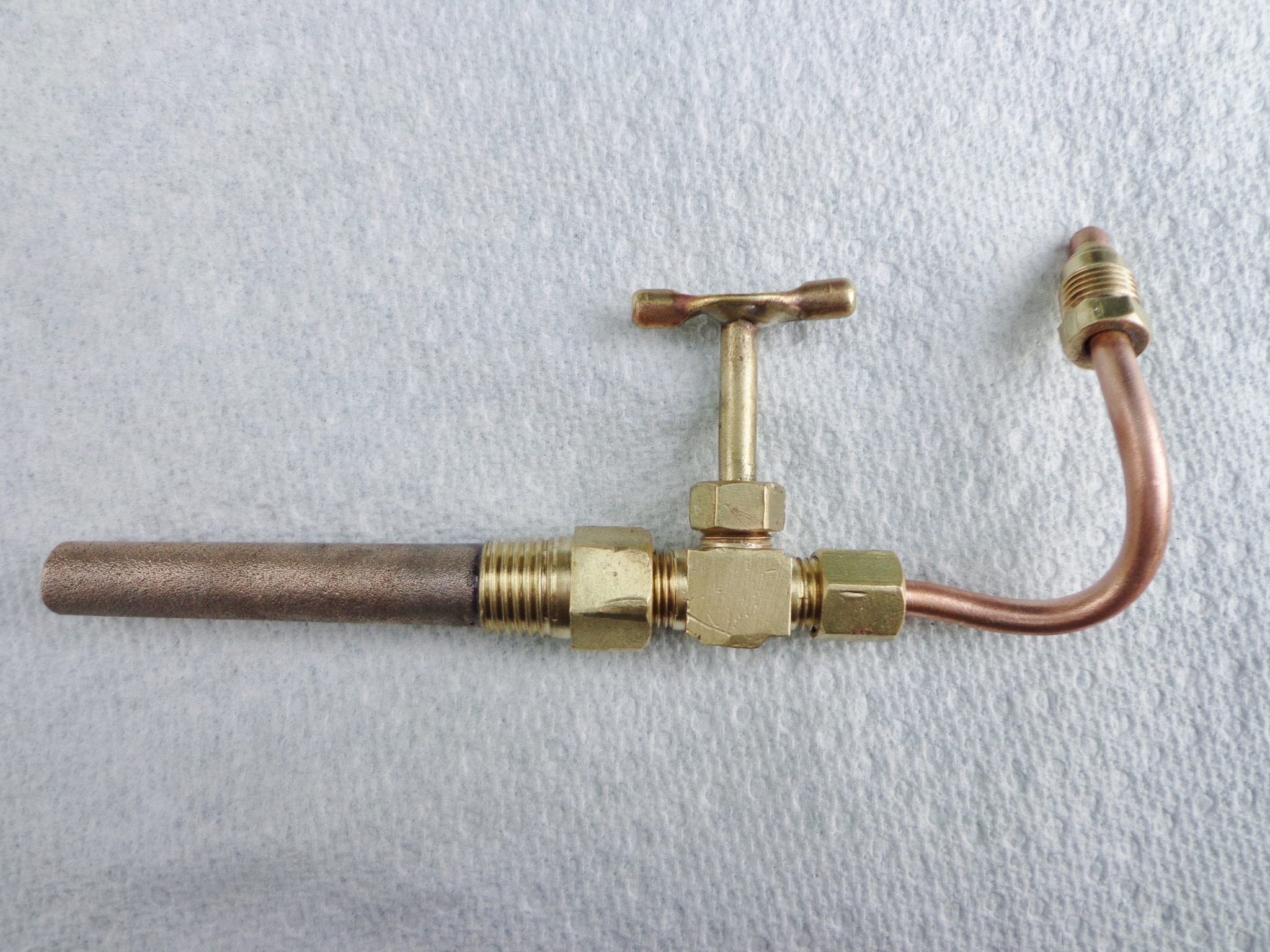

We used regular J.B. Weld on many motorcycle fuel tanks from crashing our dirt bikes. Use regular, not fast setting.February 27, 2020 at 4:30 pm #195993new carb nipple made with shorten and re-flanged brake line and JB WELD great stuff btw the brake line thread fits perfect in a carb inlet thread

needed it to replace a broken copper tube to the carb with a regular hose from the tank valve 🙂

Joining AOMCI has priviledges 🙂

-

This reply was modified 5 years, 4 months ago by

crosbyman.

-

This reply was modified 5 years, 4 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.