Home › Forum › Ask A Member › scott atwater disassemble

- This topic has 10 replies, 4 voices, and was last updated 6 years, 10 months ago by

frankr.

frankr.

-

AuthorPosts

-

January 22, 2019 at 5:57 pm #164315

I am in the process of taking down a 1947 3.6 hp, so far the fly wheel and power head are free. I am trying to remove the back plate from the foot. I can’t get the two screws on the plate loose. I have a habit of breaking things when I apply force. Help is appreciated.

January 22, 2019 at 8:58 pm #164333January 26, 2019 at 11:56 pm #164920I have used both a handheld impact driver and a powered one. Definitely cheaper to go handheld if you don’t have either.

January 27, 2019 at 9:32 pm #165137If you break it I have another case you can have.

January 28, 2019 at 11:22 am #165179Thanks for the offer, with my luck, I may have to take you up. I’ll try banging and twisting a little harder and see what happens.

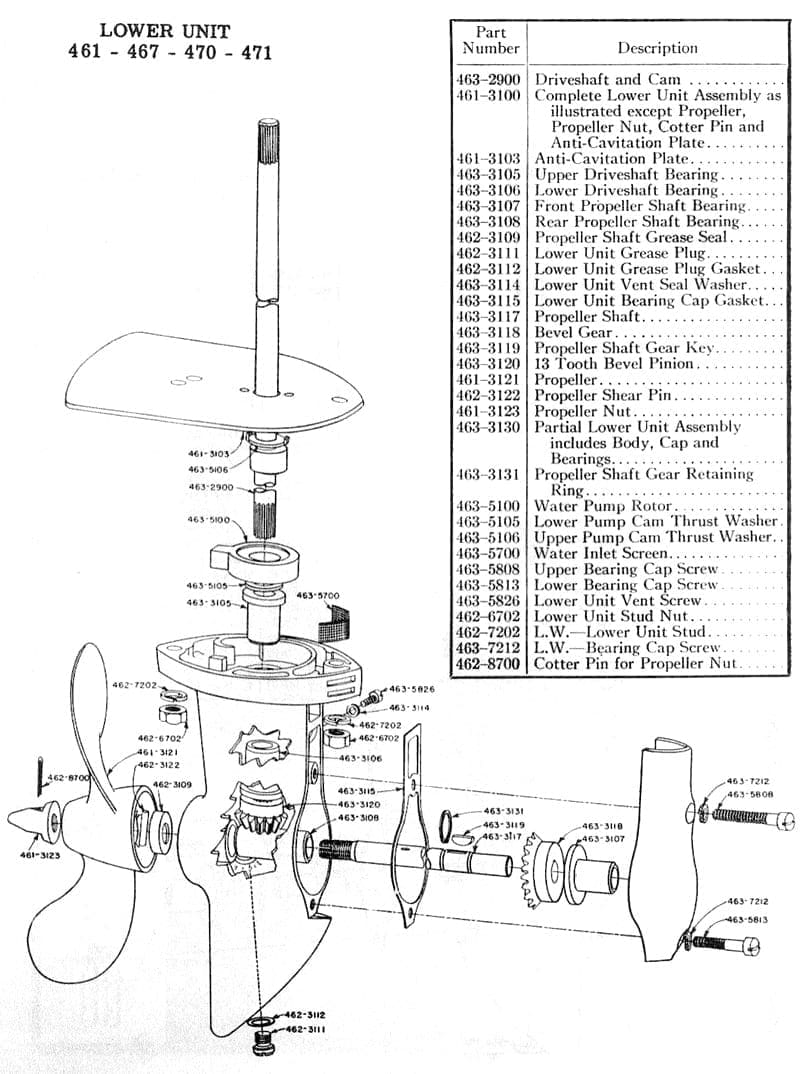

January 28, 2019 at 11:27 am #165180Thanks for the diagram, once the screws are removed, how do I get to the impeller?

January 28, 2019 at 11:54 am #165181After the screws are out, remove the cap off the front of the gearcase. That will allow access to the nut holding the front of the gearcase. Remove that nut and the one at the aft of the gearcase. Pull the gearcase down and away. Anti-cavitation plate may come with it. Impeller is in the pump cavity below the cavitation plate. It is a wobbler-type impeller (rotor) #463-5100.

February 1, 2019 at 1:10 pm #165646Thanks for the information finally got the plate off and pulled the shaft, the impeller looks good, no cracks and not dried out. Should I change it out anyway? Got another question, how is the mounting bracket removed from the shaft? If I had your email address I could send you a picture, I don’t know how to post pictures on the AMOCI website. While I’m at it, the response to asked questions is amazing from this AOMCI group. The amount of information is second to none.

February 1, 2019 at 1:41 pm #165650Requirements of a wobbler pump rotor are:

1 Must be a snug fit on the eccentric cam

2. Rotor must just flush with top of housing, not above or below.

3. Outside of rotor must just touch the inside of the housing at some point. Other side should have a space between rotor and pump housing. If you rotate the shaft, that space will move from one side to other, then disappear, then reappear and the process repeats itself. It is that space moving from one side to the other that fills with water, moving it from intake side to outlet side.

4. No excess wear in cavity or top plate. (Sand & silt wears the out)

February 1, 2019 at 1:43 pm #165651Thanks for the information finally got the plate off and pulled the shaft, the impeller looks good, no cracks and not dried out. Should I change it out anyway? Got another question, how is the mounting bracket removed from the shaft? If I had your email address I could send you a picture, I don’t know how to post pictures on the AMOCI website. While I’m at it, the response to asked questions is amazing from this AOMCI group. The amount of information is second to none.

You can send a private message to members by clicking on their name to the left of these pages (frankr)

-

AuthorPosts

- You must be logged in to reply to this topic.