Home › Forum › Ask A Member › Shaking at High RPM Running 1955 Evinrude Fleetwin Aquasonic 7.5HP

- This topic has 50 replies, 10 voices, and was last updated 4 years, 11 months ago by

fleetwin.

-

AuthorPosts

-

September 17, 2019 at 6:08 pm #183549

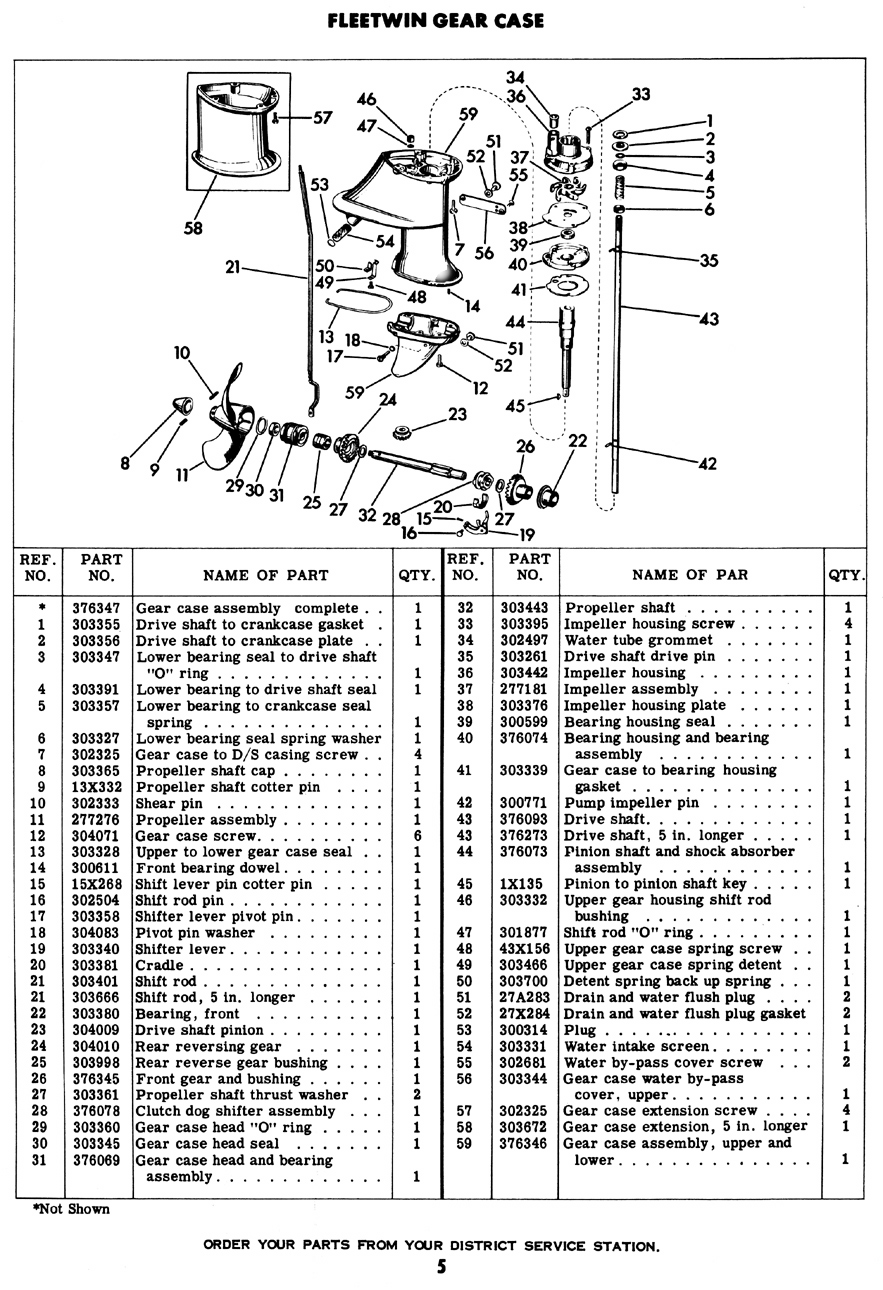

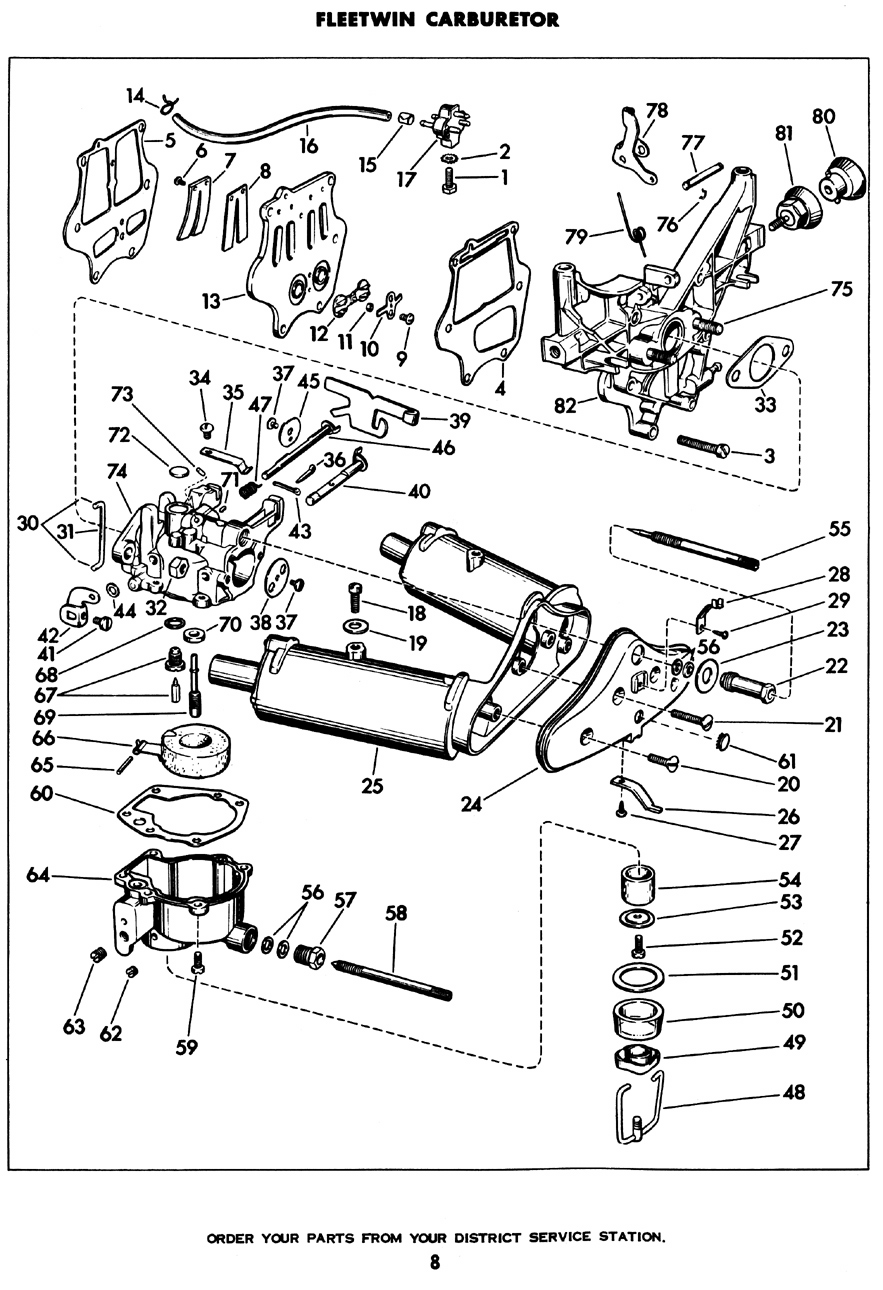

So this summer i was running full throttle and had a log strike with my outboard. Ouch… Ive installed a new prop since I the pulled the weeds out from in/behind shaft bearing . Somehow i’m getting water inside the lower unit now. Where should i start, It still runs great at low rpms however when i go to mid to high rpms it bucks crazy like it wants to jump off the boat and no its not an air pocket. Im thinking pinion shock or warped shaft? Yay. Running 1955 Evinrude Fleetwin Aquasonic 7.5HP

September 17, 2019 at 7:24 pm #183561Since you are now leaking water into the gearcase, it sounds like a bent prop shaft. Prop shaft seal could also have been compromised by fishing line or excessive weeds.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."-

This reply was modified 5 years, 10 months ago by

Bob Wight.

Bob Wight.

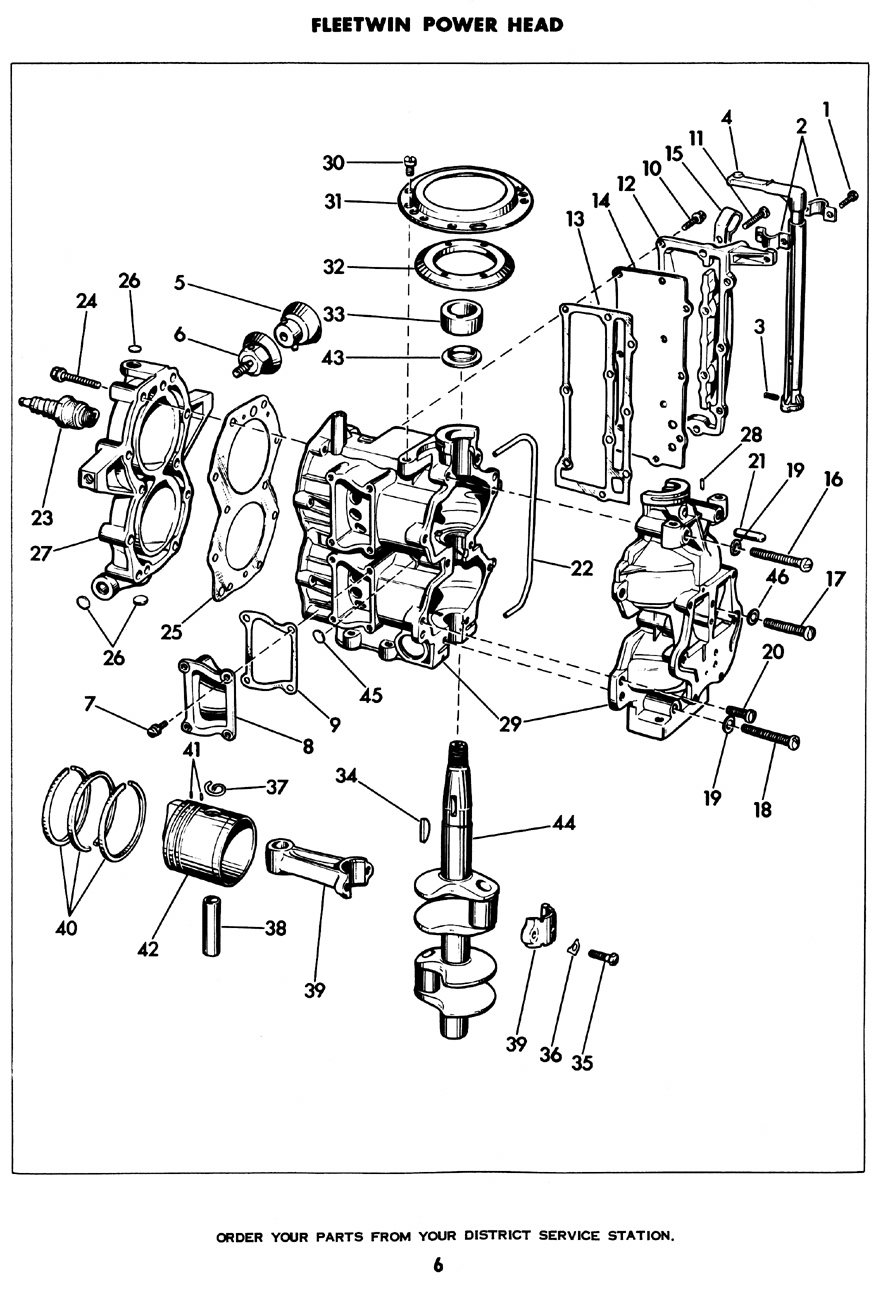

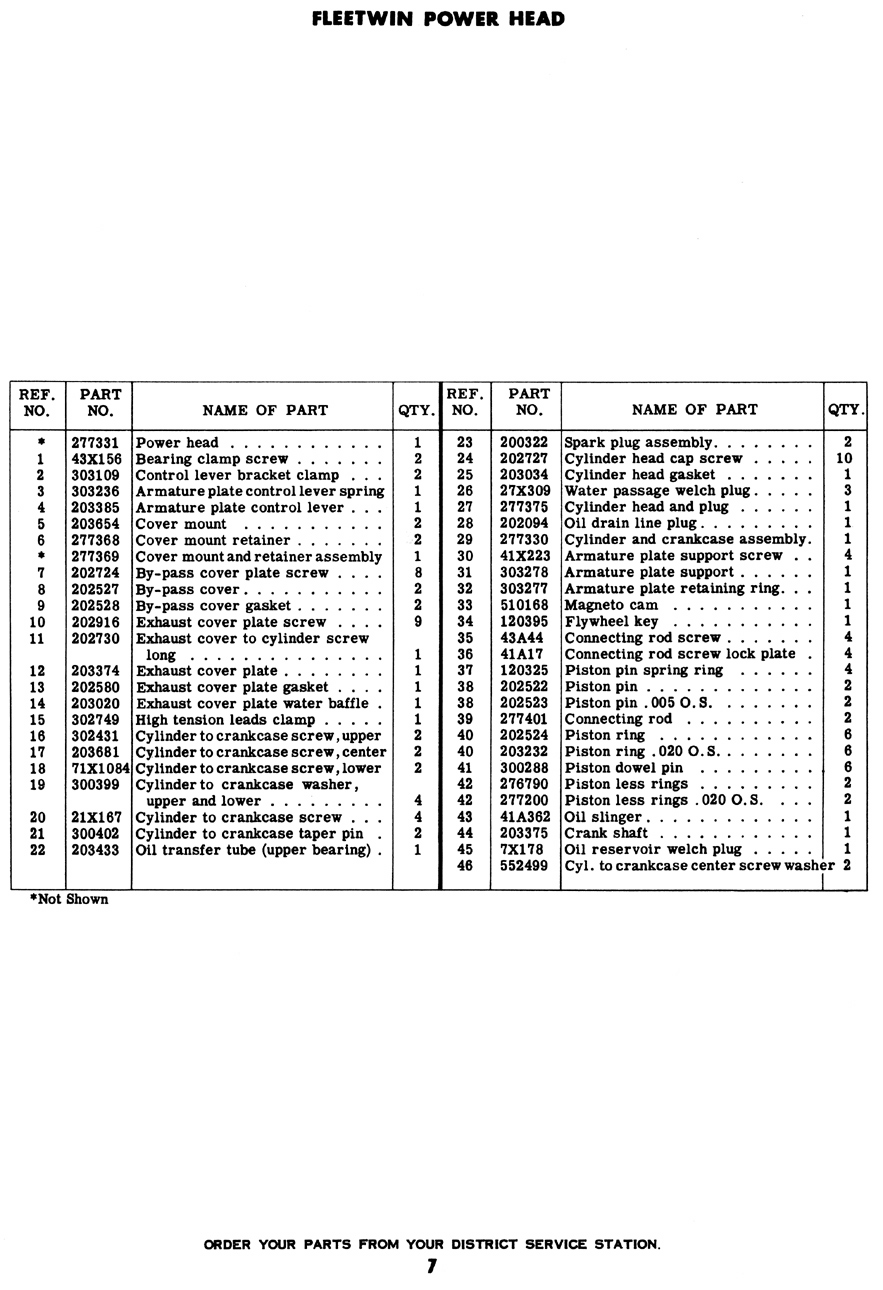

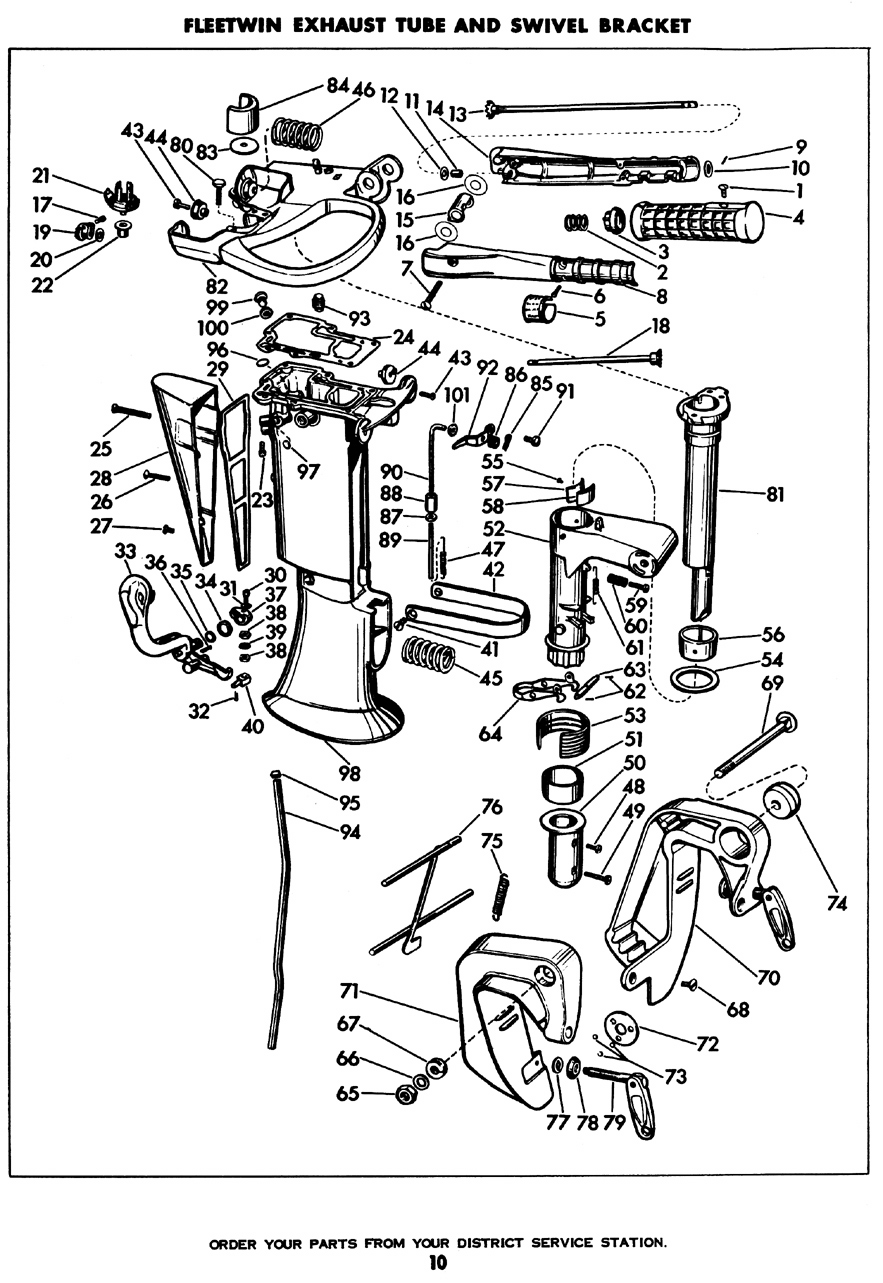

September 17, 2019 at 8:51 pm #1835681954 & ’55 were the first Aquasonics and used springs for isolation. In 1956 they switch to rubber mounts, It sounds like a serious mis-alignment issue. Many of these issues are caused by backing into curbs while trailering with the motor down. Minor hits may be straightened. Major crashes will require replacing parts.

-

This reply was modified 5 years, 10 months ago by

garry-in-michigan.

garry-in-michigan.

-

This reply was modified 5 years, 10 months ago by

garry-in-michigan.

garry-in-michigan.

September 17, 2019 at 9:37 pm #183571Bucking like it’s going to jump off the transom sounds like a worn out cutch dog to me..

September 18, 2019 at 7:26 am #183576In regards to the spring alignment. I tried this first and went ahead and replaced the springs. Still no improvement. It still shifts smooth. I have the lower unit apart now . Just getting to the gear case. No metal shavings in the oil so that’s a good sign.Just not sure if i have to replace the prop seal or something else.

September 18, 2019 at 10:45 am #183589Are you sure the replacement prop isn’t bent to? A bent blade which causes vibration like you describe can be hard or impossible to see visually. A bent propeller shaft should be obvious while turning it with or without the prop on.

September 18, 2019 at 12:08 pm #183591Just finished pulling the gearcase. Everything looks alright besides the bearing which was obviously letting the water in so i pulled it. The only trouble the bearing gave me coming off was at the end of the shaft where you place the cotter pin it was sticking. Other than that no problems and it looks straight. The prop i bought NOS in original box because the other one was ruined. Since when you use the old one it just spins and you dont move.

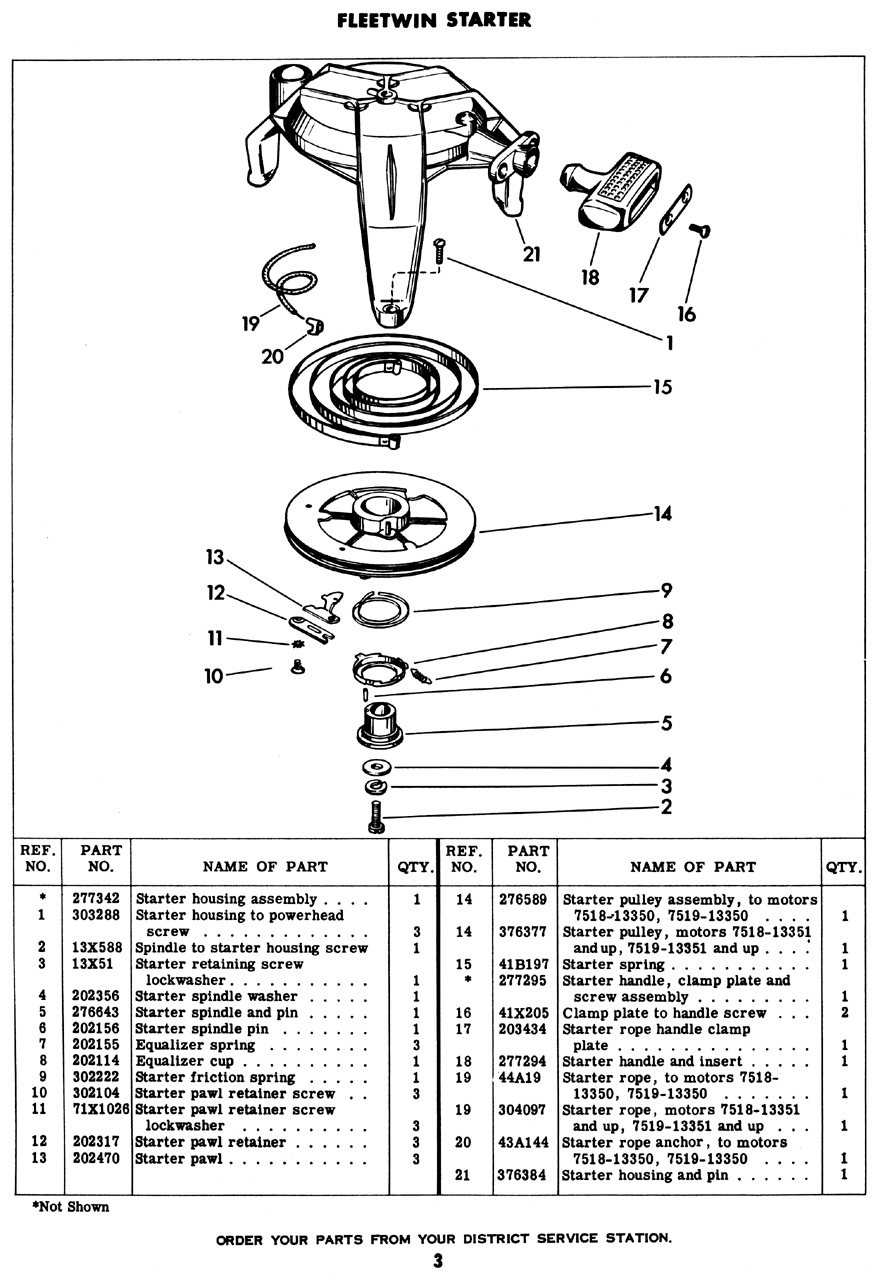

September 18, 2019 at 2:10 pm #183596Just pulled The lower unit shock absober. Its stuck and wont move. Tried moving it in vice and with blocks of wood seems like its locked up pretty good probably going to need a new one im thinking that’s the issue.

September 18, 2019 at 2:28 pm #183597Just finished pulling the gearcase. Everything looks alright besides the bearing which was obviously letting the water in so i pulled it. The only trouble the bearing gave me coming off was at the end of the shaft where you place the cotter pin it was sticking. Other than that no problems and it looks straight. The prop i bought NOS in original box because the other one was ruined. Since when you use the old one it just spins and you dont move.

When you are referring to the bearing I’m assuming you are referring to the prop shaft bearing head which contains the prop shaft seal. Could you tell if the water was getting past the shaft seal or between the bearing head and the gearcase? There is always a burr on the prop shaft where the drive pin and the cotter pin go through. I always file them off first to prevent gouging the shaft bearing and possibly damaging the shaft seal if it is still serviceable.

When you say the old prop was ruined because it just spins and you don’t move, I’m not sure what you mean. Does the propeller spin when the motor is in gear and running and it just will not push the boat? is the propeller just spinning around the prop shaft and not turning in the water? I’m assuming it must be the first scenario since there is no rubber hub or clutch in this prop, only a drive pin that passes thru a hole in the center of the hub extension and the prop shaft. There is a strong possibility that you may have sprung or broken the shock absorber in the top of the gearcase. These things tend to get more brittle as they age. If this is bent / broken / rubbing the bottom of the drive shaft bearing carrier that may be causing some of your vibration also. When these break I squeeze them back together in a vise or a press and weld the seam together. This eliminates the shock absorber effect and necessitates replacing the steel drive pin with a brass shear pin to protect the gears, but it will not destroy the bearing carrier for the drive shaft and it will not break unexpectedly in the middle of the lake and leave you stranded. While a shear pin is not the easiest thing to change on the water, it can be done and you can get back home. If the shock abosrber breaks you will be rowing or getting a tow.

-BenOldJohnnyRude on YouTube

September 18, 2019 at 3:51 pm #183599Yes i was referring to the prop shaft bearing and seal. The water was going through the behind the prop into the gearcase you could tell by looking at the bearing,it was lopsided. The prop is a aluminum and bronze prop. It got caught in the weeds and the bronze part was wore off. These specific props dont work without the bronze part.

-

This reply was modified 5 years, 10 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.