Home › Forum › Ask A Member › Sierra’s Quality Control Non-Existent?

- This topic has 26 replies, 19 voices, and was last updated 7 years, 6 months ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

October 4, 2016 at 8:08 pm #5427

A ’59 Johnson JW three horse recently came in for a full maintenance tune up but the owner preferred to use cheaper Sierra parts in the magneto instead of OMC/BRP dealer parts. Here’s what I found.

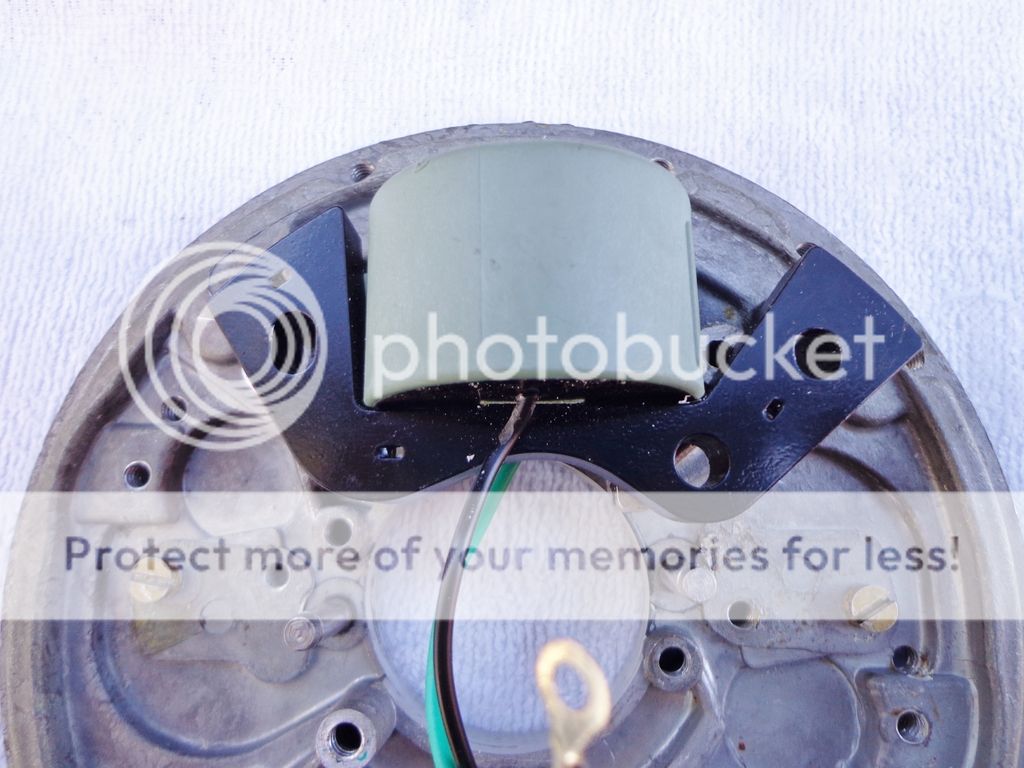

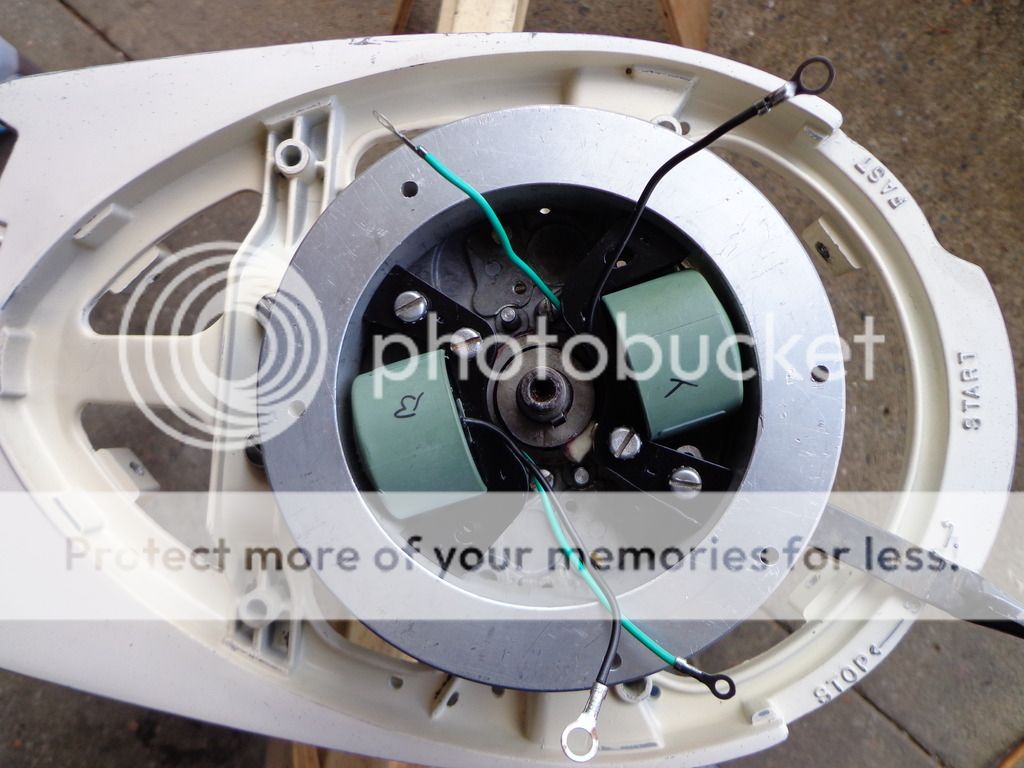

These offshore 18-5181 coils have their laminations stamped together, instead of being riveted together as OMC/BRP ones and some other offshore ones are. I’m not sure what the fit would be like on the coils from other manufacturers but the arc of the laminations is not correct, as seen while holding one in my coil locating ring.

I couldn’t get the hold down screws started without filing some of the potting material from the bottom of the coil. They just don’t line up properly without doing some grinding or filing to the coil. Only enough material was removed to get the screws started as I don’t know how thick the potting material is.

Once the coil was fastened down, there was no room for the spark plug wire or its boot. A definite alignment problem here.

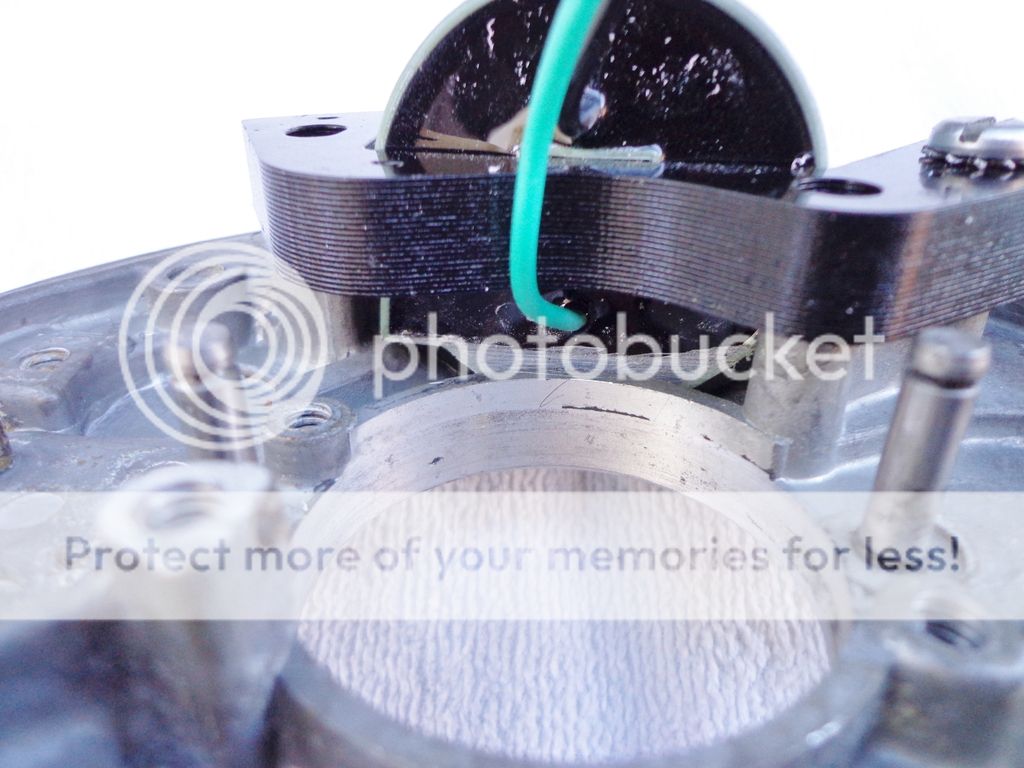

Now its time to get the big guns out and do some serious grinding.

Once the coils were secured, I still had to force the locating ring over them as they were tight. There was also all of this extra long wire to deal with so the wires were shortened and new terminals were installed.

Now it was time to open the 18-5006 tuneup kit to see what surprises it held.

Along with the points and condensers, I was quite surprised as it came with two felts (dry) and the necessary continuity clips and hold down clips! As a bonus, there were two caps of cam grease in the package! This is starting to make my day now as things couldn’t get worse, could they?

Without looking out the window, I could tell it was cloudy out as the new condensers tested out at around .30 uF instead of the required .18 – .22 uF as the OMC/BRP 580321’s do. No problem, lets get the points in and get this motor running!

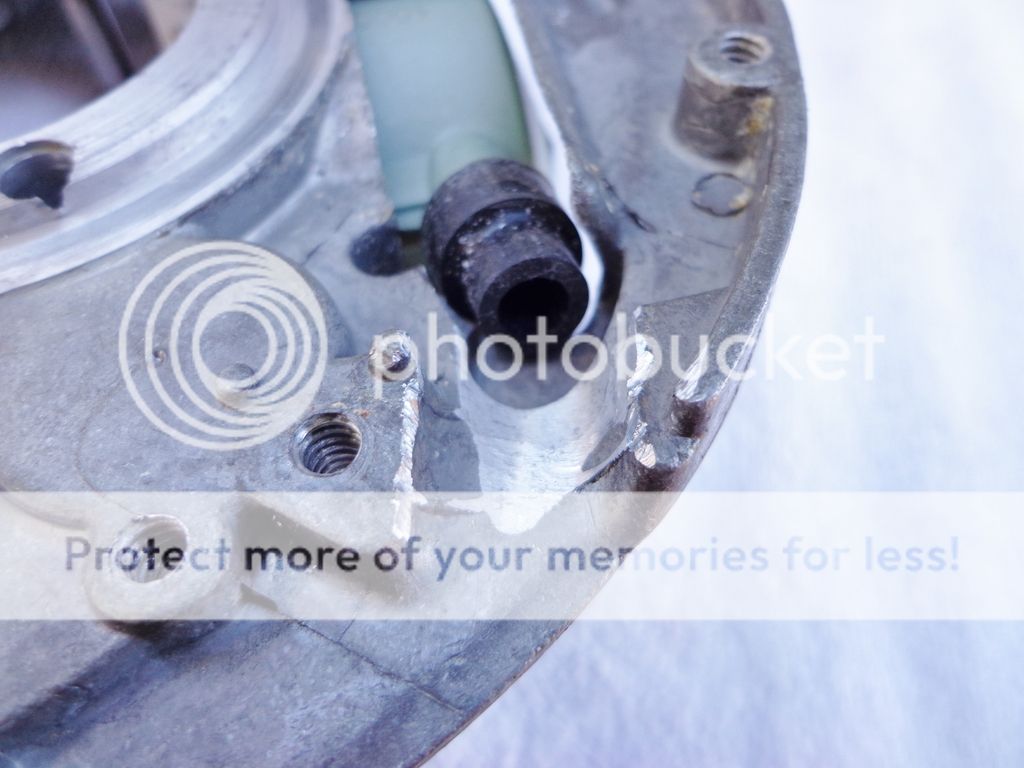

I use an ohm meter along with Franks tool to set the point gap but I wasn’t getting an ohm reading across the points. Only thru the coil to ground. What? OK, I pulled the points out and polished them with 1500 wet ‘n dry to remove any film on them. That solved the continuity problem but now I can’t set them to where I want them to be. Grrrrr. The slot in the points for the adjusting screw isn’t machined properly to allow for proper adjustment! OK, out with the adjusting screws and set them the old way, pry, pry, pry, tap, tap, tap.

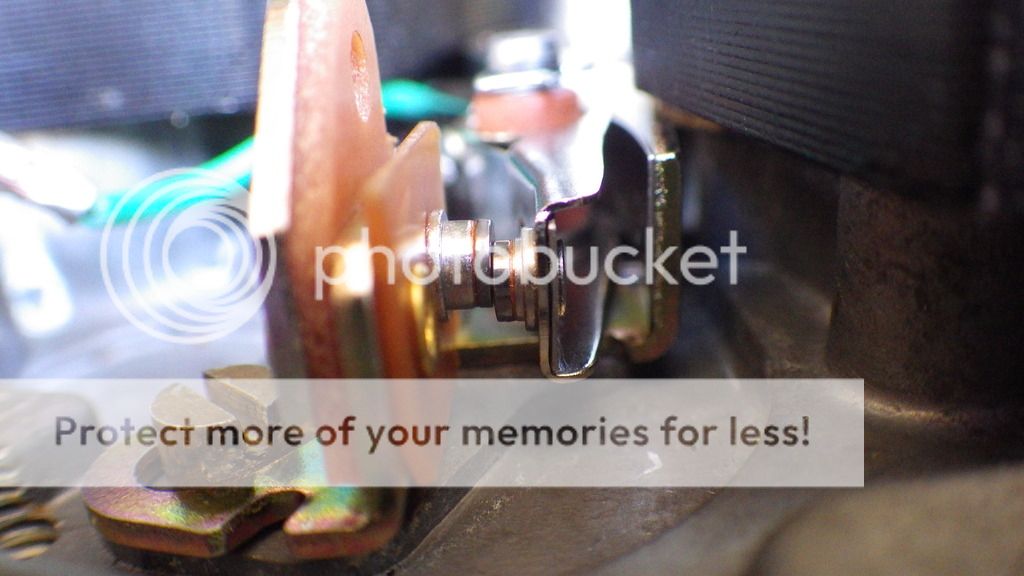

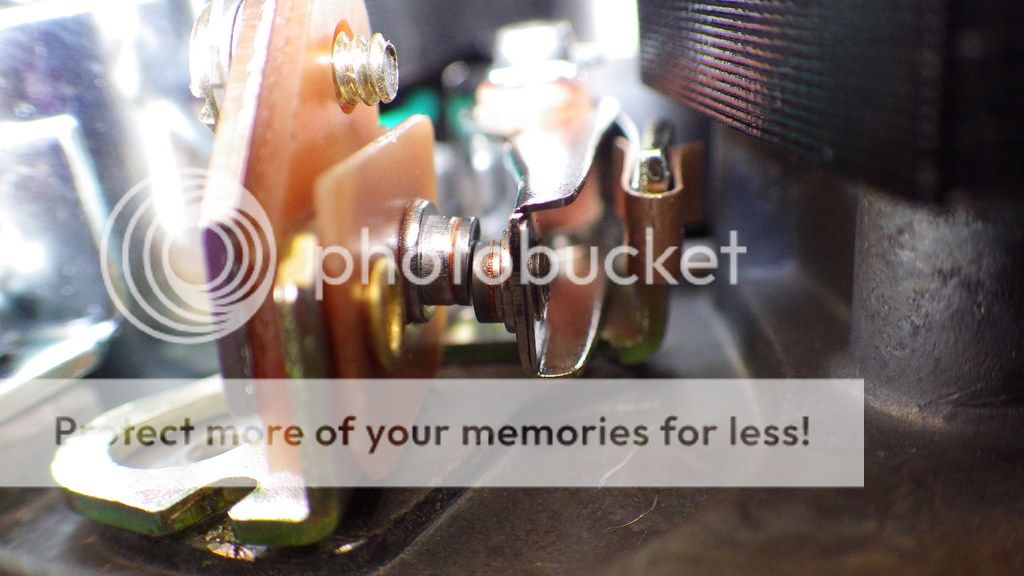

Now for the alignment. The next two pictures show the alignment after bending the fixed point to get their surfaces parallel. I wish I had take a photo of them before I did this.

Before trying to set the gap.

After removing the adjustment screw.

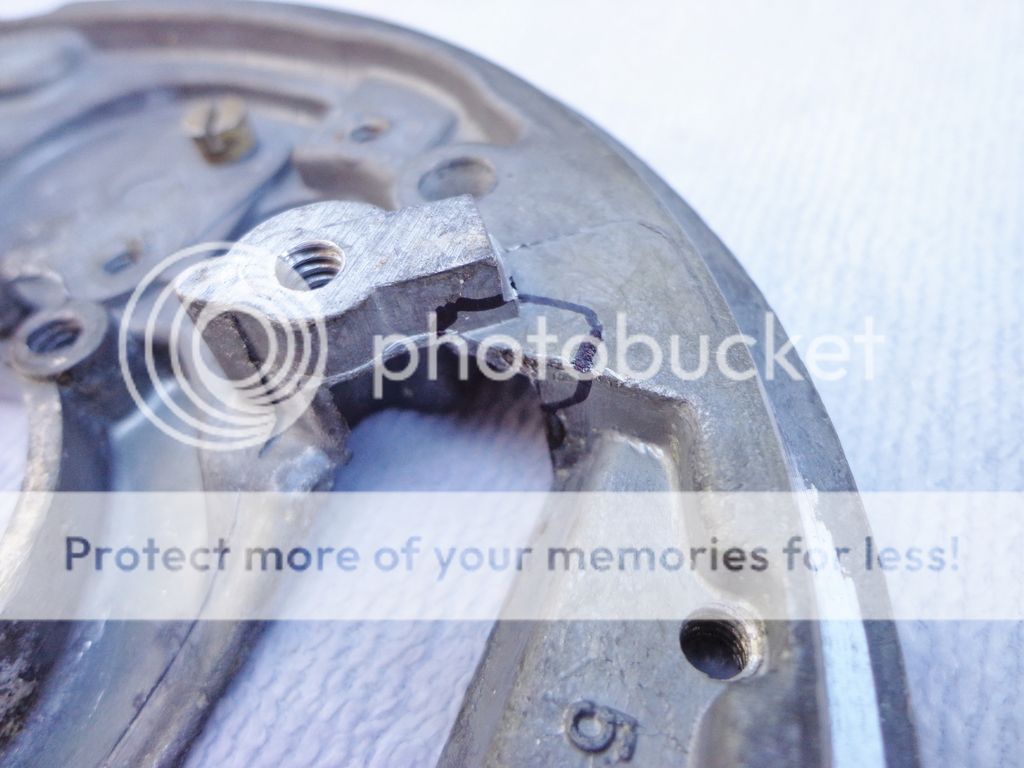

For comparison, here’s a set of used OMC/BRP points showing perfect contact area and alignment which were probably used with a good 580321 condenser judging by the amount of pitting. These points will clean up nicely and can be used again.

The only parts which did fit this motor correctly were from a 439071 carb kit I supplied and surprisingly, the Sierra impeller.

So, where is the quality control in these aftermarket parts production? 🙄

I know one thing for sure though, the next time someone wants me to use certain aftermarket parts, I just might have to say no!

October 4, 2016 at 8:24 pm #45185

October 4, 2016 at 8:24 pm #45185Well, I’m not one to throw stones, because the OEMs surely are guilty of letting quality control lapse from time to time….

But, I guess I would have just chucked this Sierra stuff (and got a refund) in favor of OEM stuff…October 4, 2016 at 8:25 pm #45186Jim, wow that’s a lot to go through with using those aftermarket parts. I’m surprised you were able to maintain the correct gap on those. I’ve tried them a couple of times, and they are so loosely built that the gap would change!

I sat through a Sierra dealers parts seminar this past winter. Listening to the rep talking, he was scolding and laughing about people who only want to use OEM. He said there parts [Sierra] are as good as or equal to OEM. I didn’t speak up, but wanted to! Seems like every year we are loosing this stuff to Chinese origin. We didn’t know how good we had it with the Prufex coils.October 4, 2016 at 8:39 pm #45191WOW! Mumbles, that is some really eye opening equality control issues!! Really pathetic if that is what they going to sell. The company should be contacted and informed.

For the past year, I have kept the old laminates from the OMC cracked coils that I find. There was a similar disscussion that was had regarding quality issues of points and coil laminates about a year or so ago.

Jim, we really appreciate you taking the time to update us on your recent findings.

Cheers buddy!

October 4, 2016 at 8:58 pm #45193mumbles, that is a lot of time and work to go through !

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonOctober 4, 2016 at 9:02 pm #45195So how much money did he save having to pay you to do all the modifications!

October 4, 2016 at 9:06 pm #45197quote Chris_P:So how much money did he save having to pay you to do all the modifications!I’m glad you asked that Chris,i didn’t want to bring that subject up

"Some people want to know how a watch works, others just want to know what time it is"

Robbie RobertsonOctober 4, 2016 at 9:09 pm #45200All I can say is that I would hate to be a Chinese astronaut. I’d be pooping my pants in fear, constantly, knowing they made the rocket.

Long live American manufacturing!

October 4, 2016 at 9:49 pm #45204hahaha i read this kind of story and realize that it ain’t all bad to be living in a world of antique motors where I depend on one guy (moi) to do my repairs and supply replacement parts…. haven’t had to install a Chinesium part on a rowboat motor yet…… haven’t ever found a worn-out Sierra water pump piston in any rowboat motor either!

Best,

PM T2October 4, 2016 at 11:32 pm #45213I was going to ask the same question as Chris.

-

AuthorPosts

- You must be logged in to reply to this topic.