Home › Forum › Ask A Member › South Bend Lower Unit

- This topic has 30 replies, 7 voices, and was last updated 2 years, 5 months ago by

Bob Wight.

Bob Wight.

-

AuthorPosts

-

June 25, 2023 at 4:02 pm #277373

I’m running into some resistance trying to remove the prop in picture. With prop nut removed I’m not able to slide the prop off the shaft. I’ve tried gently tapping on the prop with a rubber hammer but it still won’t move. Please advise as to what the problem might be. Does anyone have or know where to find an exploded view of the lower unit?

June 25, 2023 at 5:58 pm #277381

Its just stuck.

They can be a real pain to get off sometimes.

Many of the early Johnson screws, nuts and

bolts are of a thread that is no longer used so

be careful with and keep track of them.

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

June 25, 2023 at 9:00 pm #277394Hi Tubbs,

Nice picture of the assembly.

It appears it may be difficult getting penetrating oil or lube to the prop shaft in a effort to loosen the prop.

Is it a good idea to disassemble the lower unit to check the internals.

Peering in through the grease filler port I can’t see any evidence of lube.

Might I need to disassemble the lower unit and remove the prop shaft to get the prop off.

Roger that on keeping track of all the nuts, bolts and quite frankly everything.

June 25, 2023 at 10:30 pm #277401I use a small two jaw OTC or Craftsman brand puller to

remove stubborn props!

1 user thanked author for this post.

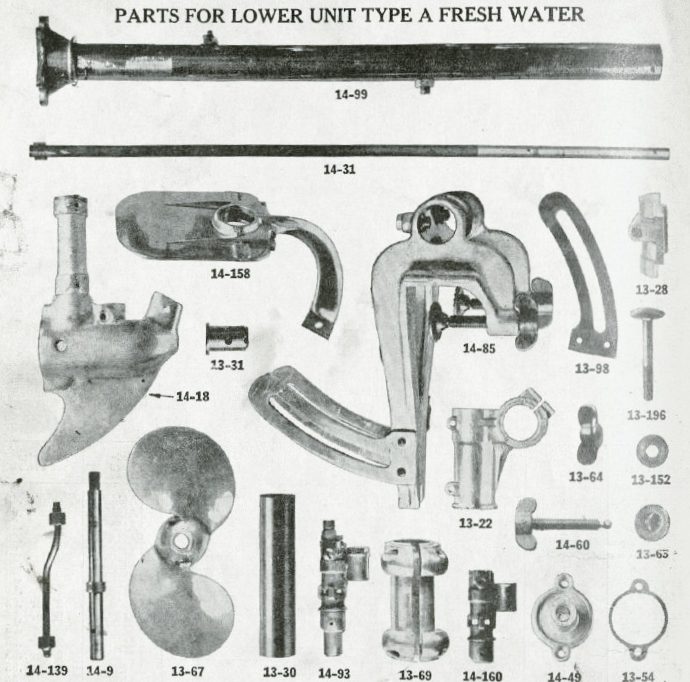

June 25, 2023 at 11:47 pm #277413In no particular order, some of the parts making up the lower assembly.

1 user thanked author for this post.

June 26, 2023 at 8:57 am #277421

The Prop is stuck from just before the shear pin hole back.

I’d like to see what condition the L U is in inside. Not seeing

anything in there could be a bad sign. There are no seals so

some grease goes out the shafts. This lubes the bushings but

water enters replacing the grease. If water was left in there

to sit for decades you can have a prop gear that is fine ¾

of the way around and the teeth rusted off to some degree

on the rest of it. Maybe the last person to run it used gear

oil and it has all run out.

Using it without inspecting it first? Well if it’s junk you can’t

hurt it. Try moving the prop shaft up and down & side to side

to check the condition of the bushing. It is what it is but this

can give you some indication of what you might find inside.

Turn the prop back and forth to check the gear lash. Do this

every ¼ turn of the prop. Expect some slop but if it isn’t

excessive filling the L U with grease and using the motor may

free the prop up some. If the prop nut is tight up to the prop

I’d take out the cotter pin and back the nut off a couple holes.

You want to use lubriplate 105 or John Deere corn head

Grease in the gear case.

Looking at your L U picture, the steel driveshaft tube and

not having a cavitation plate indicate its early cast tank

Johnson. If you don’t want to disclose your serial number

would you say if it is in the hundreds or what thousand’s?

Tubs.

A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

June 26, 2023 at 7:56 pm #277446Remove the two screws on the gearcase head and you can pull the prop,prop shaft and bevel gear out of the case as one unit.You can then more easily remove the prop.The drawing shows the setup in the gearcase.

1 user thanked author for this post.

June 26, 2023 at 10:17 pm #277458a good possibility is to get some oil of wintergreen from the drugstore and use it as penetrating oil, give it time to work in, ive had great results with it.

1 user thanked author for this post.

June 26, 2023 at 10:18 pm #277459I positioned the lower unit to horizontal position and sprayed kroil on the prop shaft and after letting it kreep in the prop easily slid off.

Not much corrosion inside and minimal backlash between the gears.

There is NO cotter pin hole in the prop shaft and brass nut holding the prop in place.

You’re right a thorough inspection and cleaning is needed.

I have the Lubriplate

Serial # 4215

June 27, 2023 at 9:11 am #277474

Serial numbers from 3931 to 7500 are 1923.

The cast tank Johnson’s have a strong interest

in the hobby. Your LU is in better condition than

most. An indication your motor has been well

cared for. If you want to disassemble it any farther

you should remove the pump first. Don’t want to

beat this fastener thing to death but the rope

starter screws are the ones most likely to have

been chewed up and are really hard to come by.

They are way to small to be used with a puller.

Here is a link on how to remove the flywheel and

one with some history on the early Johnson’s you

might find interesting.

Tubs

https://youtu.be/RWgE9XiIBnk

https://www.yankeeaomci.org/johnsonat85.htm

.A "Boathouse Repair" is one thats done without having tools or the skills to do it properly.

-

AuthorPosts

- You must be logged in to reply to this topic.