Home › Forum › Ask A Member › Suitcase fuel tanks

- This topic has 7 replies, 5 voices, and was last updated 8 years, 10 months ago by

legendre.

-

AuthorPosts

-

June 30, 2015 at 6:15 pm #1901

I just picked up a pair of OMC suitcase or tall boy pressure tanks. I’ve seen pictures of them a while ago, but never in real life. Any details, like years in production or parts lists? They seem to operate like the "newer" pressure tanks, but have an additional valve of some sort on top. Any information is appreciated.

Thanks

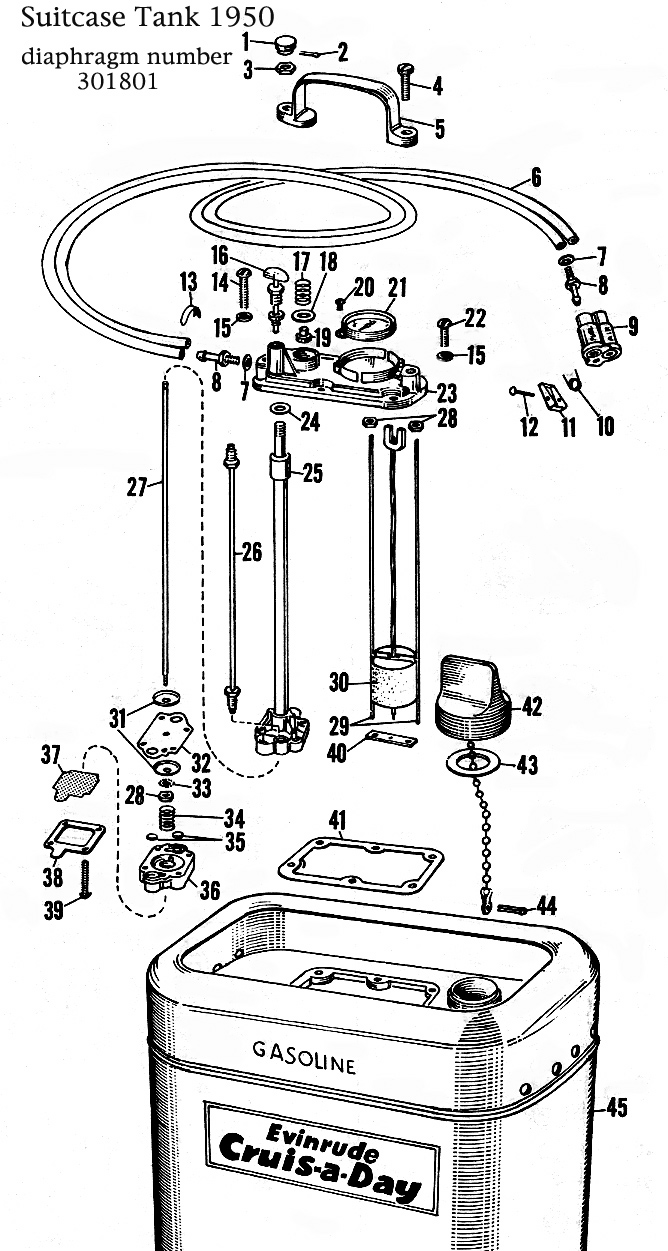

Joe P in MAJune 30, 2015 at 6:48 pm #19229The tall tanks were offered from 1949 through sometime in late 1951. The Johnson QD and SD motors used them and the Evinrude 14hp Fastwin used them. Some interesting features are the diaphragm being smaller and located low down rather than in the housing like the later tanks, the magnetic Rochester fuel gauge and the pressure shut-off valve on the "fuel out" line. While parts are not available (that I know of) you can make the diaphragm and gasket from bulk material.

There was also a second tank that resembled the "tall boy" tanks but had the more typical design and diaphragm. These were only offered for a short time (late 1951 into 52 if I recall) before the rim was removed.

June 30, 2015 at 8:13 pm #19235

June 30, 2015 at 8:13 pm #19235

June 30, 2015 at 11:28 pm #19254

June 30, 2015 at 11:28 pm #19254Great! Thanks.

July 1, 2015 at 1:00 am #19262@Garry or anyone else In The Know..

Could you provide a little background on how this fuel system works? If there’s a (pump?) diaphragm in the tank, why would the tank need to be sealed for pressure – doesn’t it simply draw fuel from the tank, up to the motor?

Or does the diaphragm pump pressurize the atmosphere in the tank, which then forces fuel up & into the motor? I assume then that the point of the magnetic fuel gauge is that it requires one fewer pressure-sealed element piercing the tank..?

July 1, 2015 at 1:26 am #19264The pump /diaphragm is just used to prime the carb. Then it operates like any other pressure tank, on crankcase pressure from the motor.

Replacement gaskets and diaphragms are available, but easy to make your own as Art said above.

http://www.vintageoutboard.com/collecti … repair-kit

July 1, 2015 at 2:56 am #19272quote :Could you provide a little background on how this fuel system works? If there’s a (pump?) diaphragm in the tank, why would the tank need to be sealed for pressure – doesn’t it simply draw fuel from the tank, up to the motor?The OMC pressure tank system did not have a fuel pump as such. It incorporated an air line off the crankcase that pressurized the fuel tank to 4-6psi forcing the fuel out of the tank and up to the motor through a hose that had a fuel and air line. This system was used (as I noted above) starting in 1949 and ran through 1959-60 – there were some modifications and updates throughout the years.

The tanks all had a provision to pump fuel up to the carb to start the motor via a manual primer pump. Once started, the pressure took over provided that the cap was screwed down and there were no air leaks. All the tanks had a pressure relief valve in case the pressure got too high. And as noted, the early tanks also had a fuel shut off valve so you could leave them pressurized – thereby saving your manicure and not having to prime them. 😆 That feature was eliminated on the 1952 and later tanks, frankly, it just isn’t that hard to prime them!

Pressure fuel and oil systems were quite common on cars, tractors and other machinery for many decades. Many chain saws still use a similar system today for bar oiling. A common reason cited for not using a fuel pump is not having to pay GM royalties on their fuel pump patent. (Something that dates back to Henry Ford and the Model T &A) I don’t know if that is true in the case of OMC, but the pressure system was/is safe and reliable – I’ve been running motors with it for over 40 years and had no more problems than with later siphon systems.

Some of the many styles of OMC pressure tanks:

July 1, 2015 at 3:39 am #19275Ah, OK.. So the diaphragm pump is there to prime the carb, but it isn’t used to feed fuel to the running engine..?

Now the magnetic fuel gauge makes more sense.. they’d need another set of seals to use a purely mechanical drive.. and the torque on the fuel gauge shaft is so low, that the seals alone might create enough friction to make the gauge pretty well useless.

Yet the question remains – if they already had a diaphragm pump in use, why not integrate the pump to the motor, and implement the typical suction system used on later tanks?

-

AuthorPosts

- You must be logged in to reply to this topic.