Home › Forum › Ask A Member › T2Stroke

- This topic has 62 replies, 7 voices, and was last updated 5 years, 11 months ago by

discoboater.

-

AuthorPosts

-

April 6, 2018 at 1:26 am #73496

OK, no that throttle/idle stop screw is touching the stop, thought the throttle cable was just too loose…

In any event, it is never going to idle correctly set up like this, the throttle plates are held open slightly at dead idle because the throttle cam is hitting the roller…

The idle speed must be way up also…

I’m trying to decide on the best way to approach this sync process with you, let me look around at home to see if I have a service manual, so I can post the pages/instructions and review the process with you…Won’t be home until Saturday…DonApril 6, 2018 at 5:26 am #73508Thanks again Don. I actually have wondered about this before. Even when I had the carbs all off, I dont seem to remember the throttle plates sitting any different. I had presumed that this was how they looked closed. I would say fairly certainly that the difference that those plates are off is less than 1 degree. In regards to the idle, I do not think it idles very high, this is something that would be pretty obvious to me. Having spent the better part of my life wrenching on cars, and everything else, I am familiar with what a high idle is like. It actually seems to be more the opposite. But this could just be this air leak rearing its head. I usually need to keep the warm up lever up for quite a while, especially compared to my 65′ merc 100. The service manual I use is the here tinfo.no/lib/evinrude/manuals/1973-1991johnsonevinrude.html. The sync process seems a bit daunting to me. I am looking forward to your guidance. What tools will I need ? No rush ! I appreciate your time and helpful knowledge. …..Jay

April 6, 2018 at 11:40 am #73512I’ve seen faulty crankcase recirculation check valves on these motors many times…. it will cause a very rough idle, along with more smoking at idle. But it wont affect the running quality of the engine at higher RPM’s. I think there are at least six of them located behind the carbs on the intake. They are a one way check valve that can stick open. BRP is proud of them too.

April 6, 2018 at 1:01 pm #73517Well, I think the best approach for now is to deviate a bit from proper procedure and just pull that throttle cam back off the carb roller by loosening the jam nut and working the thumbwheel back until the cam is off the roller/not touching…Yes, we are skipping many steps and making some assumptions, but will get some answers quickly. Once the cam is backed off the roller, we will need to ensure all the throttle plates are completely closed…Again, the engine will never idle correctly if any of the throttle plates are cracked open, even the slightest bit. There are those little adjustment screws on the carb linkage, probably best to loosen the ones on the bottom and top carb (again the cam can not be touching the roller at this point), this will allow the throttle plates to close, then just tighten the set screws up again. Do not mess with the screw that secures the throttle roller on the middle carb.

I am traveling today, but can talk by phone early Saturday morning….Might be best to review this by phone to make sure I am clear about what we are doing…Again, this is far from the correct sync procedure, but it will answer some questions quickly….DonApril 6, 2018 at 2:55 pm #73524Thanks Gents ! Interesting Jerry, this is what Dan in TN (T2Stroke) thought might be my problem. I am going to proceed with Don’s advice/guidance here. I will begin with these throttle plates/carb and sync adjustments. It might be a bit backwards, since if it is not the cause of these issues I will need to pull the carbs all off again to get to these valves, and would probably need to repeat the sync process again. Hey, at least I will be comfortable with syncing after a few goes at it ! The weather here has not been great lately, (they call it mud season for a reason !) Its looking like constant rain (and snow) for the next several days unfortunately. I am hoping tuesday brings some clear skies and workable conditions. I will update as soon as I can get my hands dirty again. Thanks for all the help fellas !

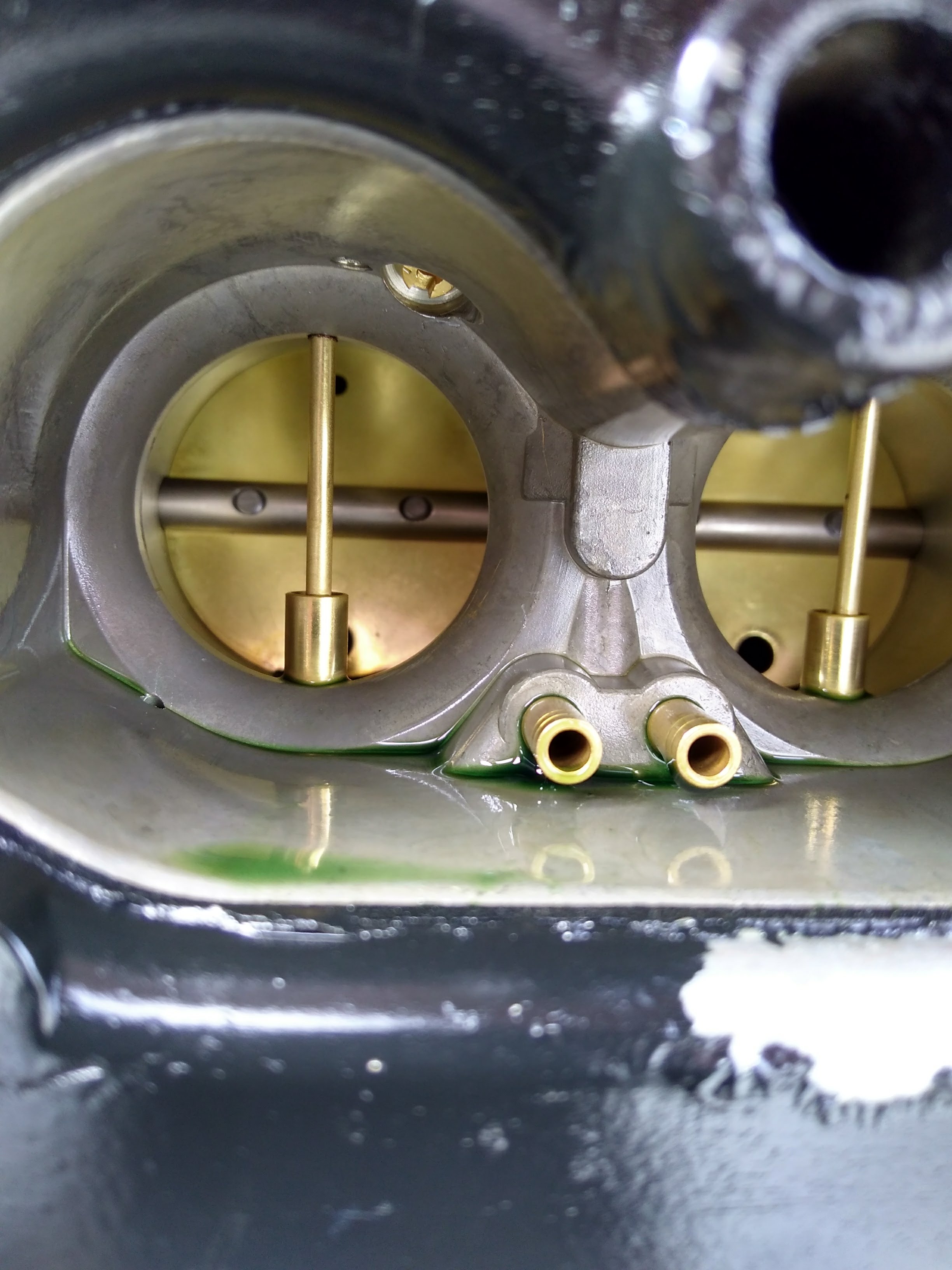

April 8, 2018 at 9:37 pm #73636Hey Don, I just noticed something…. I went out to try to back off that throttle cam. I inspected the carb throttle plates a bit closer. I noticed if I focused on the top carbs plates while turning the top carbs cam forward(down) that the plates fully closed. Oddly the adjustment screw for this (which is on the middle carb cam has been covered with gasket sealer ? Surprised I hadnt noticed this before. I believe if I loosen this I will be able to change the adjustment of the arm that guides all of these plates. Is it a bad idea to do this without making any other changes ? This clearly shows the position of the throttle cam on the roller. Not touching, so it is not pushing the plates open. You can also see the covered screw.

April 11, 2018 at 1:00 pm #73805OK, so you are saying that in this picture, the throttle cam is NOT touching the roller? Kinda looks that way…Are you also saying that it appears as though one of the throttle plates is cracked open slightly? If so, this will surely caused sneezing at idle/low speeds. I can see that someone has backed the throttle roller/cam pick up adjustment screw all the way to the bottom of its travel.

Do me a favor and back off the long idle stop screw (long SS screw towards the top of the throttle arm) out a few more turns to ensure this cam is NOT touching the roller, then we can sync the three carbs properly….DonApril 11, 2018 at 1:07 pm #73806The three carbs are synchronized using the two little screws on the top and bottom carb that control the vertical connection rod. That cam roller pick up screw gets adjusted later, so make sure it is NOT touching the cam now…

Did you get my PM with phone number? This is not a hard process, but it is difficult to explain using key strokes, will be easier to talk with you…DApril 11, 2018 at 1:43 pm #73808Thank you for taking over Don. I’m still here observing. My offer still stands for anything I have that may help you get this motor going properly. I have jets, etc. May have a couple of those recirculation valves.

Don is on the right track. Lets do the simple stuff first. I’m a little worried about your WOT RPMs, but don’t want you to go down to a 15" prop either. No performance there. These engines will do OK at 5000RPM WOT & still have good hole shot. In an overly loaded situation you just can’t expect the same take off. Running the motor at WOT at 4500RPM is not good! That is peak load & should be avoided. Just pulling back on the throttle is fine. Just wanted to state those facts.

Starting to feel well enough to post a little. Already missed several meets this year down in FL. That’s not going to work out well at all! Hoping to be back on the water soon.PS: Looks like we are dealing with a 1988 model motor instead of a 1989. Big difference ignition wise! J150TLCCA on the chip in powerhead. I thought it was an X model (25") midsection. Again only a minor difference. Can make a difference in jetting. Thanks for clearing that up.

Dan in TN

April 11, 2018 at 7:23 pm #73833Thanks Dan and Don. Glad to see you posting again Dan. Thanks for all your help, I will definitely let you know if I need anything.

Don, the cam is absolutelty NOT touching the roller. I can easily spin the roller freely. I think the picture has a bit of a depth illusion, as the area that appears to be touching is actually further towards the block.

I did get your pm and info, and responded as well.

However, I went out to mess with it yesterday, (phone number in hand) and started by trying to adjust the vertical linkage rod. It took me a couple of tries to sort it out correctly, but…. I eventually got it adjusted so that the plates are all closing ! Here is a pic showing the top carb plates. If you look at my previous pictures closely, you will see that these plates were the most noticeably off. Not anymore. 😀 I havent tried to start it up yet but intend to do so fairly soon.If for some reason this doesnt solve the problem I may call you. I still am wanting to properly sync and time, using a TDC tool and timing light. I also would pursue the re circulation valve direction if these other options fail. I will report with more ASAP.

-

AuthorPosts

- You must be logged in to reply to this topic.