Home › Forum › Ask A Member › T2Stroke

- This topic has 62 replies, 7 voices, and was last updated 7 years, 1 month ago by

discoboater.

-

AuthorPosts

-

April 29, 2018 at 7:07 pm #75028

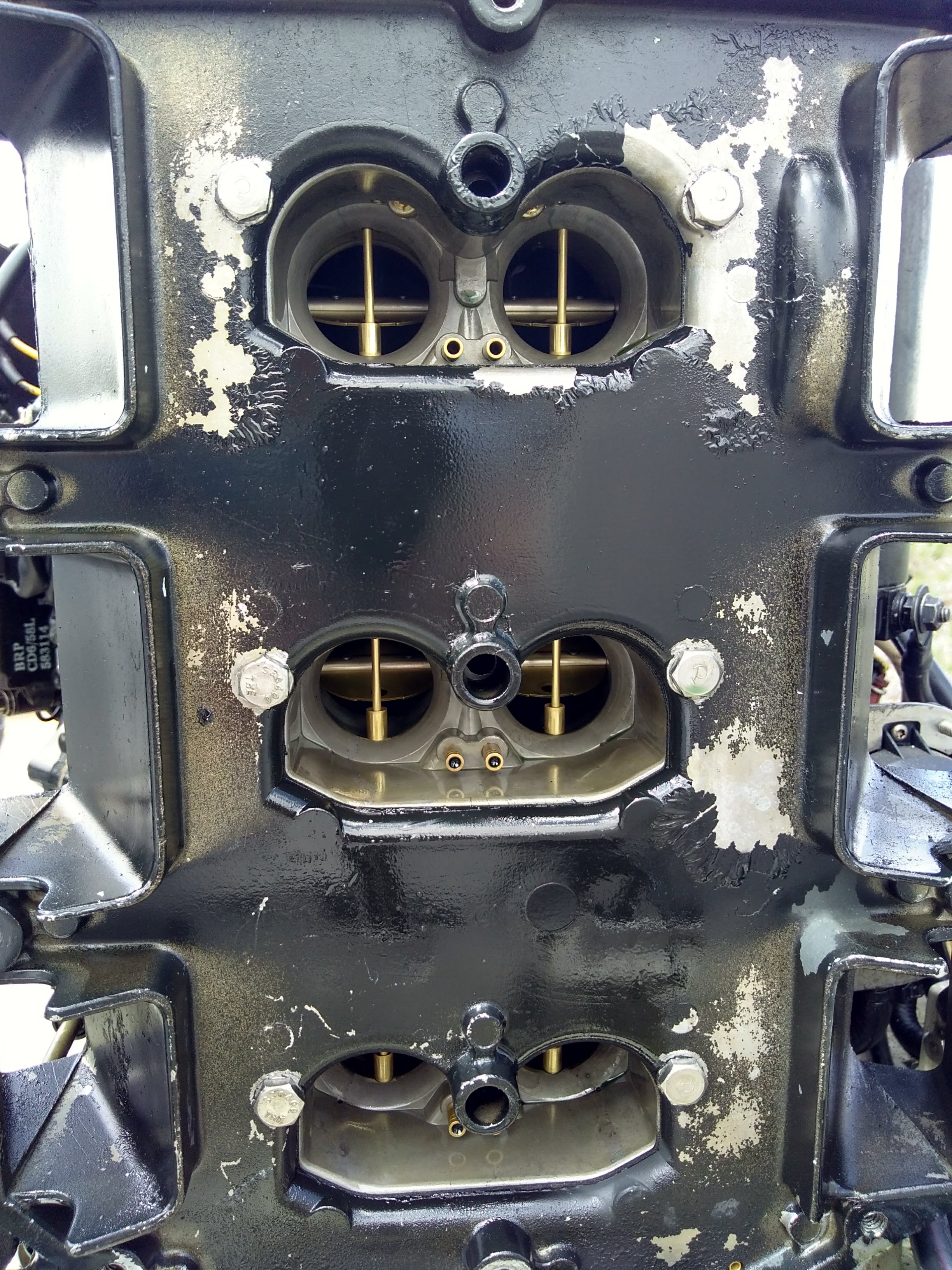

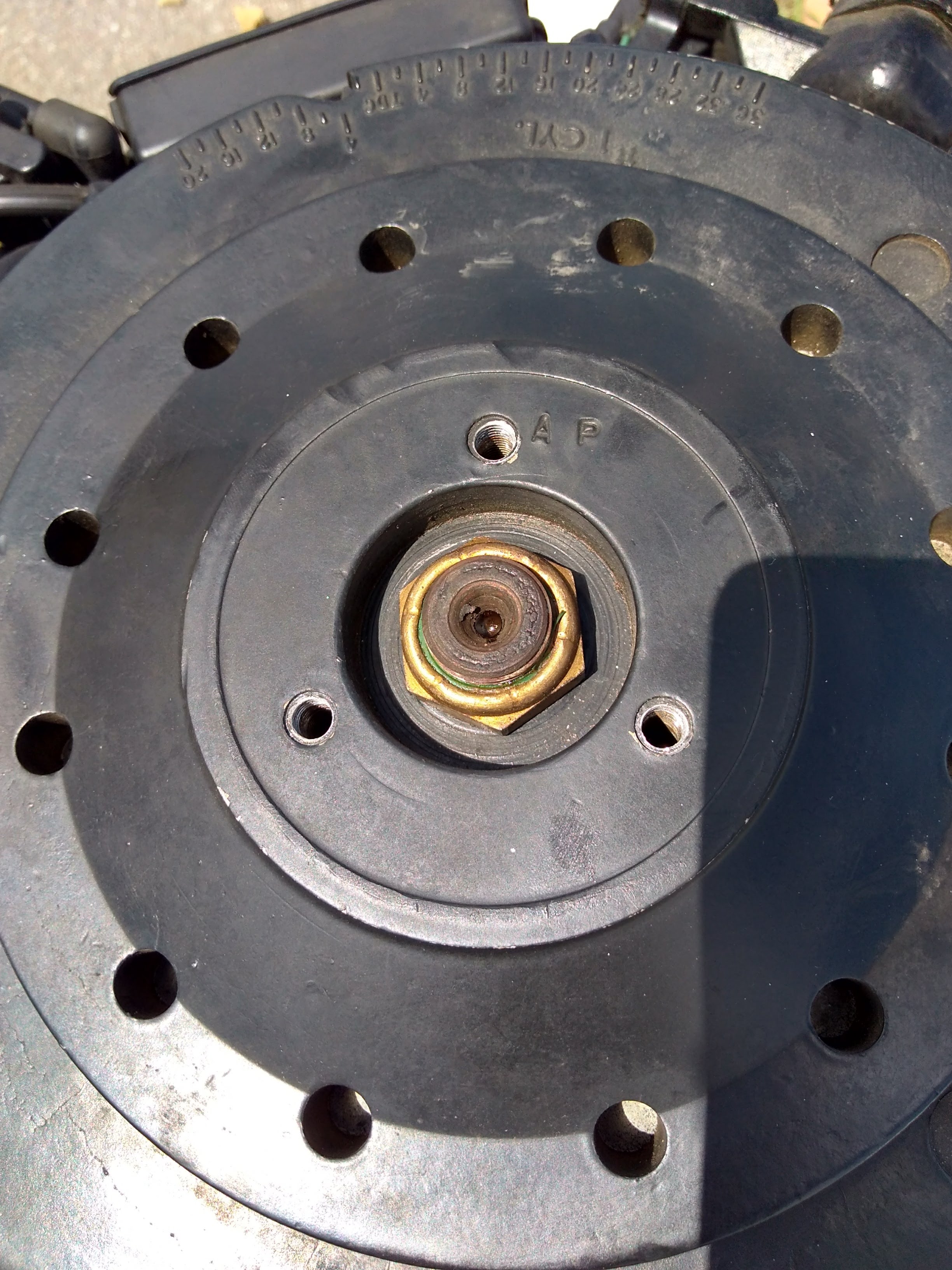

Don, I took pictures of the flywheel nut and the roll pins with the throttle level at wot. It does not appear as if the flywheel nut has been tampered with. It also does not appear as if the roll pins are fully vertical, likely this is a side effect of me adjusting the arm so that the plates fully close at idle. I would trade off the higher top end speed for a more preferable smooth idle. In regards to the idle/rpm/tach ; WHEN it is actually idling, it seems like a very appropriate rpm. I do believe the tach is omc, I will check out the back this afternoon. I will let you know what I come up with in regards to the TDC tool. It looks like next weekend will bring some decent weather, if so I will take her out and attempt to get some video footage. Heres the pics I took.

May 1, 2018 at 4:48 pm #75154OK, yes, the throttle plates are not opening fully….And, yes, does not seem like the flywheel nut has been "messed with"…

I have the sync instructions, and will upload them now. Have a look at the instructions and then it will be best for us to talk by phone, so I can help you understand what you are doing and why it is important….Have you found a long reach plug yet? These instructions are for 1980 model V6s, exactly the same except for the cam pick up timing adjustment…Yours has a little thumbwheel on the plastic linkage which allows it to be changed without removing it from the metal cam and rotating it…In other words, yours is easier to adjust…

DonMay 1, 2018 at 6:45 pm #75159Thanks Don, I will study the sync instructions later this evening when I get a chance. I have not secured a TDC device yet, probably today. I did check you the tach yesterday. The gauges are all the same brand teleflex, they are definitely original, not certain if this is omc’s gauge brand ? I did look at the back, but couldnt tell what "setting" its set at.

May 1, 2018 at 6:46 pm #75160May 1, 2018 at 7:33 pm #75161Yeah, that is not an OMC tach, probably Teleflex like you say….

There is an adjustment on the back, but I don’t know what setting Teleflex prescribes for this engine…

Let me know when you get a long reach plug, then we can talk by phone…DonMay 19, 2018 at 2:07 am #76304Hey Don, I have a bit of an update here. So I do have some longer thread plugs around, I havent checked them to see if the threads will fit in the outboard and if they are long enough. Finding the plug stop tool was much more difficult than I anticipated, by now I could have had one from an online store ! I have read the sync instructions a few times and plan on printing them out before I attempt this. Thanks again for uploading those pages, I really appreciate it. Although they are fairly easy to understand directions, there are a few points that are a bit intimidating, and a few questions I had as well. However Im going to jump back just a bit first….

You had previously asked for a video of the engine at Idle and when having the issue. I did manage to take the boat out three times since my last post and got some footage of the engine and tach at idle when running well. I dont have any of it exhibiting the issue at the moment, and also am in a bit further with the starter.

The First of the 2 days the engine seemed to be running better than normal, it fired up a bit quicker but was having the same starter/solenoid issue. The solenoid was not engaging the gear into the flywheel, the gear is also pretty worn away near the top…from grinding on the flywheel. I have been having to wind the gear into the flywheel teeth first, then turn the key and pray. It sometimes will engage normally once the boat has been running for a while, but not always, and the condition began to get worse on this day. Before the next time out I noticed a good amount of leakage below the l/u. It seemed to be coming from the upper vent screw. I havent gotten into this, but I presume it could be some water getting in. More fun. Heres the footage of the engine running on this day its a zip file so you will need to download it. I cant get the vids up any other way they are mp4. Let me know if it doesnt work for you.

The Second of the days the starter was behaving similarly, only engaging occasionally. The stalling issue was worse, especially while pulling a skier. So I very reluctantly drove the 2 1/2 hours down to the city and bought a brand new factory brp starter for $250. I got home late and didnt install it before the next mornings outing…. bad choice !

The next day was a bad day. It took longer than normal at the dock to get the engine started. Once going she seemed pretty good, brought up to plane, seemed pretty smooth, except for at low speed and of during the specific rpm range where it always stalls. Then it stalled out and refused to start. I had to hand wind the gear into the flywheel before each failed attempt. My wife and buddy paddled us towards the dock. Another boat noticed us and pulled us the rest of the way in. First time having to get pulled back in this boatSo now not only am I hoping to get this thing synced properly, Im also putting a starter in ! The first point in the sync directions that has me a bit tripped up; Between 1d and e. Says in "d" to hold piston firmly against stop (tool) while marking the underside of the flywheel. I presume you do this by rotating the flywheel clockwise, as this will move the piston. However the next step "e" says you then rotate the flywheel clockwise until the piston touches the stop again. How is it possible to rotate the flywheel further while the piston is being kept from moving by the stop tool ? Do I remove the tool/plug then after a slight flywheel move reinstall, then continue rotating ?

And then with steps 6 and 7. Step 6 uses a timing light, I dont currently own one, I would be interested in buying one, is there any special type needed for outboards ? Is there any that you would recommend ? Step 7 looks pretty complex. Both steps say the engine needs to be running, in step 7 it says not on a flushing device, I presume that means not on the muffs.

I will probably look the instructions over a few more times before getting my hands dirty. Ive been super busy lately, it seems like every second Im cramming in as much as possible so that I can make some time to get back out on the water! Im hoping to have some time on sunday afternoon to start messing with these sync adjustments. Thanks again for all of your patience, time, knowledge and being so considerate. I hope this finds you well. I will definitely call you if I get hung up, otherwise I will do my best to not hassle you !

May 19, 2018 at 10:21 am #76310OK, watched the short videos, seemed like normal idling RPM…

It is best that we talk by phone, so I can explain the sync instructions. This is not a hard operation, but can be tough to understand off the written page…DonMay 19, 2018 at 8:10 pm #76337Thanks Don, Will do when I get into it. This thread has almost 2000 views, so hopefully its helpful to others out there too…..unless they are just viewing for purely entertainment purposes. LOL !

May 19, 2018 at 8:18 pm #76338That is a standard method for finding Top Dead Center on a flywheel. Go clock ways at least an inch and a half past top dead center. install the engine stop. Turn back against the stop and make the first mark. Now turn it clock ways almost a full revolution until the piston hits the stop again. make the second mark. Top Dead center is centered between the marks. If the workers at the factory are doing there job, your center mark will be under the "T" on the flywheel and no adjustments will be necessary. . .

May 20, 2018 at 5:49 pm #76417

May 20, 2018 at 5:49 pm #76417Thanks for simplifying this for me Garry. Appreciated.

-

AuthorPosts

- You must be logged in to reply to this topic.