Home › Forum › Ask A Member › throttle stiff on 1955 evinrude

- This topic has 13 replies, 6 voices, and was last updated 6 years, 9 months ago by

frankr.

frankr.

-

AuthorPosts

-

July 25, 2018 at 9:44 pm #10670

I have a 1955 evinrude 15 hp that I’m working on. The tiller throttle is very stiff and will jump the gear if I try to twist to fast. I’ve pulled the handle apart and cleaned everything but the problem persists. Have any of you run into this issue? Any Ideas as to what could be causing this?

July 25, 2018 at 10:36 pm #80120Did you undo the link to the magneto advance to see if the magneto

itself is too tight?Prepare to be boarded!

July 25, 2018 at 10:49 pm #80121Wiggle all the parts till you find which is stove up.

July 25, 2018 at 11:44 pm #80122Thanks Buccaneer, I just checked the magneto advance. Its not super easy to move but it does move. Im thinking it might be a combination of the Magneto being too tight, worn gears on the tiller handle, and something too tight in the tiller handle. As I moved the advance I could see and feel the gears slipping in the handle. Anyone know a good source for the gears in the handle? Can they be replaced or do I need to look for a new handle?

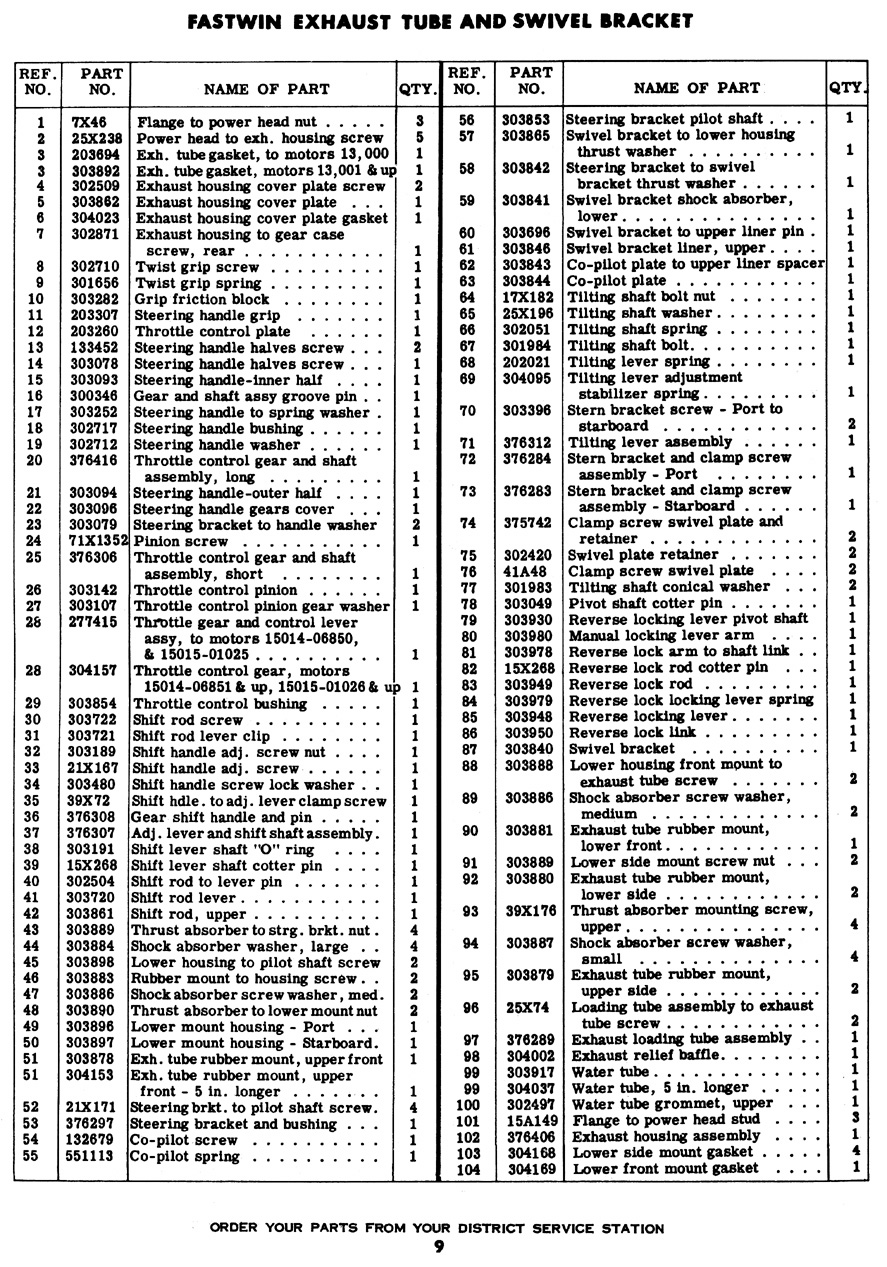

July 26, 2018 at 12:09 am #80123You can replace the individual throttle gears and shafts. Here is a link to a site where I’ve bought a lot of quality used parts. This particular link is for a 1953 model but I believe they are same part numbers as your 1955 motor.

http://thebrazilianconnection.com/53e15parts.html

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

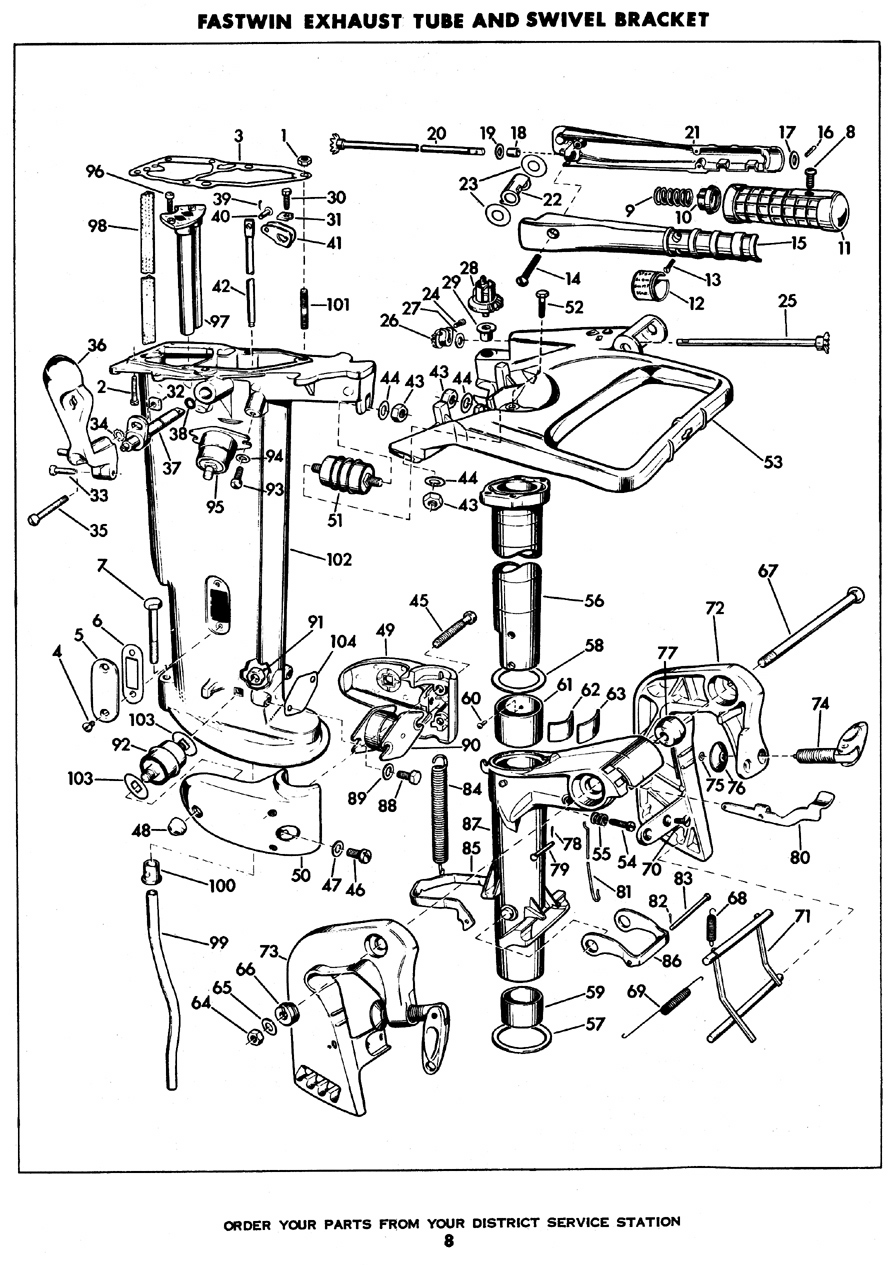

"Every time you remove a broken or seized bolt an angel gets his wings."July 26, 2018 at 12:21 am #80124OK, on the side of the powerhead is a vertical throttle shaft. The bottom end of that shaft slides into a slot on the bevel gear that moves it. That bevel gear has a pin on the bottom that goes into a nylon bushing in the steering bracket. It is common for corrosion to build up around that nylon bushing, causing it to squeeze tightly on the bevel gear pin. That’s why I said to wiggle it to see if it is too tight. Solution is to take it apart and clean the corrosion out and re-lube.

Another common problem area is where the shaft rotates in the tiller handle. But you said you took it apart and cleaned it up.

The gears were significantly changed mid-year 1956. The new style will fit your ’55 and are a vast improvement. Gears are sold as gear and shaft assembly, and you have to change both g/shaft assys if you decide to update it. They are kind of $$ unless you find some used ones.

July 26, 2018 at 12:42 am #80125Frankr is correct – I forgot about the gear change in 1956. These would be a much better solution if you need to replace the gears. Also a good suggestion to check the bushing on the advance gear. I had to replace the nylon bushing and clean out some corrosion on the steering bracket to free up the throttle on my ’72 Evinrude.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."July 26, 2018 at 12:46 am #80126The early models used a stamped gear that was prone to slip.This was replaced with a cast gear which is much longer lasting. That tiller was used on 5.5 to 18 horse models for many years. Higher horse models would require shortening the shafts. . . 😎

July 26, 2018 at 12:52 am #80127

July 26, 2018 at 12:52 am #80127I had one motor that I had to add a washer behind the gear to

make the gears mesh tighter, and it no longer slipped.Prepare to be boarded!

July 26, 2018 at 1:18 am #80130OK, seems like it is something like Frank/Garry says, that vertical gear plastic bushing…

There are a few problem areas in the tiller also…

The friction collar #10 gets seized/stiff/dried grease into the throttle grip #11. The only way to fix this is to pry the collar out of the tiller, clean it off and relube the mating surface.

Another common problem is that the speed indicator collar #12 expands outward and binds on the throttle grip #11. This is repaired easily by removing the indicator collar and compressing it before reinstalling so it fits tightly around the aluminum tiller handle and does not bind on the tiller grip. -

AuthorPosts

- You must be logged in to reply to this topic.