Home › Forum › Ask A Member › Timing Question

- This topic has 32 replies, 10 voices, and was last updated 3 years, 10 months ago by

Yellowstone.

-

AuthorPosts

-

May 26, 2020 at 11:14 pm #204123

I’ll add I used the multimeter, not my feeler gauge with the other timing method and it worked right away. I put the flywheel nut back on up top and use a wrench to turn it to get the “Top” arrow to aim at the point.

May 27, 2020 at 4:13 am #204127If you can set the points without using the tool, you can do it using the tool. The tool has nothing to do with the gap. It just indicates when the gap is correct.

Are you using the meter with all of the wires hooked up to the points? If so, you are going to have an ohm reading both with the points closed and open. When they are closed, the circuit is thru the points to ground and when they are open, your meter will sense the circuit thru the coil to ground. Can you turn the chirp off and watch the ohm reading on the meter instead? The meter has to be set to its lowest reading, usually 200 ohms or less. It should read zero or very close to zero ohms with the points closed but just as they start to open the reading will increase slightly as it is now reading the resistance of the primary winding in the coil. You want this change to happen as the pointer on the timing tool is in between the timing marks on the mag plate. This change of ohm readings happens as the points are just starting to open and you will not see any visible gap between the points as this happens. The ohmmeter reading lets you know when its happening.

For years the OMC/BRP points have been made in Turkey and I’ve never had any problems with them but I don’t know where they are made now. If the rubbing block on them is a bit short they will be a bit harder to set and they may need a nudge with a screwdriver to get them where they should be. Here’s a link to a previous thread where someone was having a similar problem with their points. Note the readings on my ohmmeter and the position of the timing tool in the photos.

https://aomci.org/forums/topic/problems-gapping-points-on-qd-19/

May 27, 2020 at 8:00 am #204130Thanks Mumbles. I will take another look using this information as well!

May 27, 2020 at 8:30 am #204131You bring up a good point Mumbles with using a multi-meter with the coil and condenser still “in circuit”.

I always use a “buzz box” and that’s not an issue.

This is one of those mysteries that one wishes was right in front of you so you could solve,

or pull your hair out trying!Prepare to be boarded!

May 27, 2020 at 9:10 am #204139You bring up a good point Mumbles with using a multi-meter with the coil and condenser still “in circuit”.

I always use a “buzz box” and that’s not an issue.

This is one of those mysteries that one wishes was right in front of you so you could solve,

or pull your hair out trying!Buc,

I recently picked up a Buzz box as well. It worked great on my KA-37 as you don’t have to unhook everything, and I could hook into the kill switch wiring with the flywheel in place. Lots of ways to skin the same cat!

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

May 27, 2020 at 9:35 am #204145Yellowstone, where did you get your timing fixture? It is unlikely, but possible that it is marked wrong. But you said it works on other motors??

May 27, 2020 at 11:37 am #204153I am with Frank, could be marked wrong, also what motor are you working on?

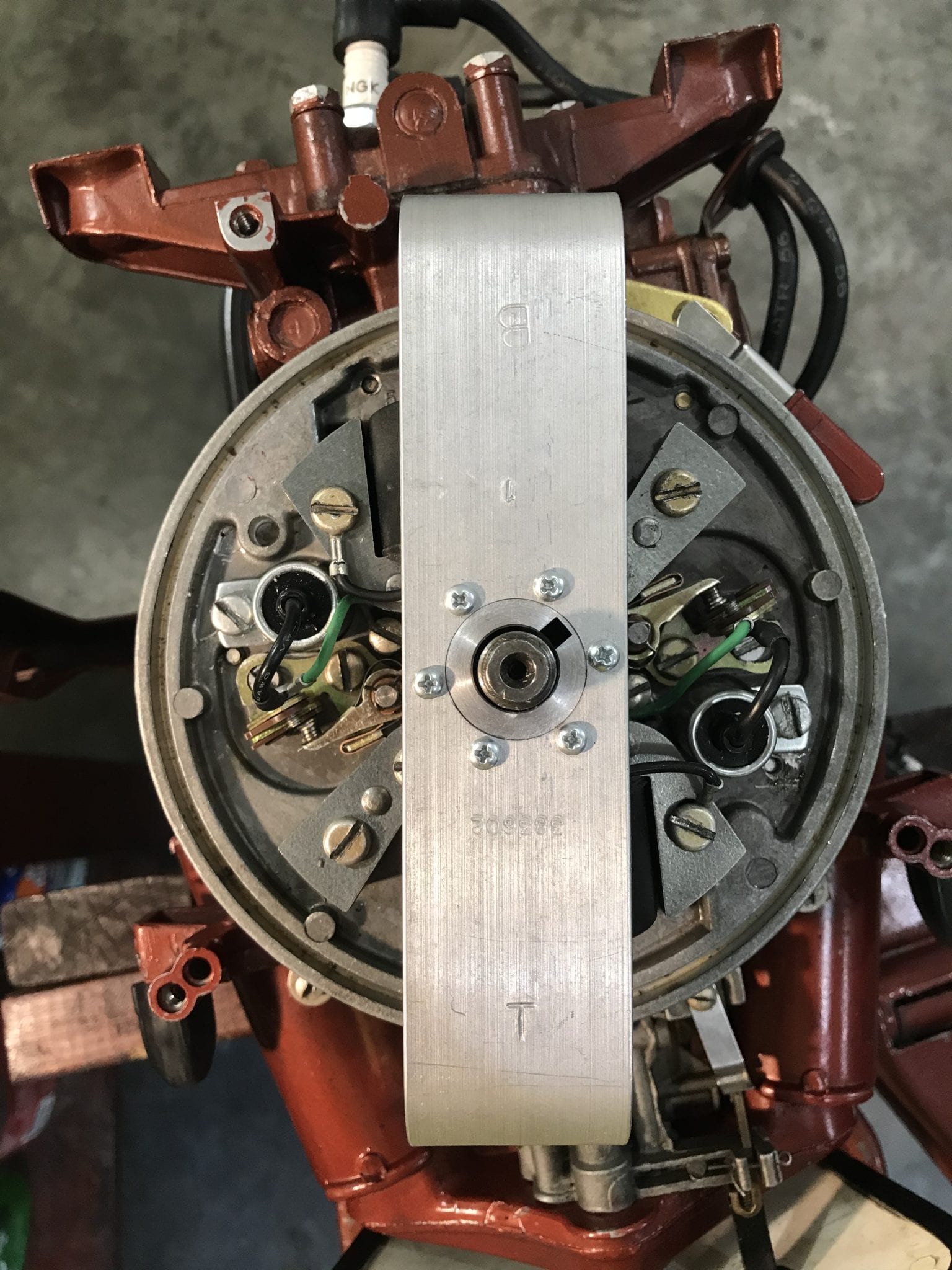

Can you attach a pic of the tool showing the entire top of the tool? so I can see the “T” and “B” marks in the same picture.http://www.richardsoutboardtools.com

classicomctools@gmail.comMay 27, 2020 at 12:00 pm #204155Thanks. Is this what you are looking for? In this photo, the hash mark on the tool is pointed right in between the two lines on the mag plate. And its a 1956 Johnson 5.5.

-

This reply was modified 3 years, 11 months ago by

Yellowstone.

-

This reply was modified 3 years, 11 months ago by

Yellowstone.

-

This reply was modified 3 years, 11 months ago by

Mumbles.

Mumbles.

May 27, 2020 at 12:03 pm #204157If I may make a suggestion, it is easier to do if the plugs are removed from the engine.

David Bartlett

Pine Tree Boating Club Chapter"I don't fully understand everything I know!"

May 27, 2020 at 12:03 pm #204158And I stand corrected. I used the #2 tool on 3 hp motors before with good success. I haven’t used the #1 yet on 5.5s.

-

This reply was modified 3 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.