Home › Forum › Ask A Member › Timing Question

- This topic has 32 replies, 10 voices, and was last updated 3 years, 10 months ago by

Yellowstone.

-

AuthorPosts

-

May 27, 2020 at 12:50 pm #204163

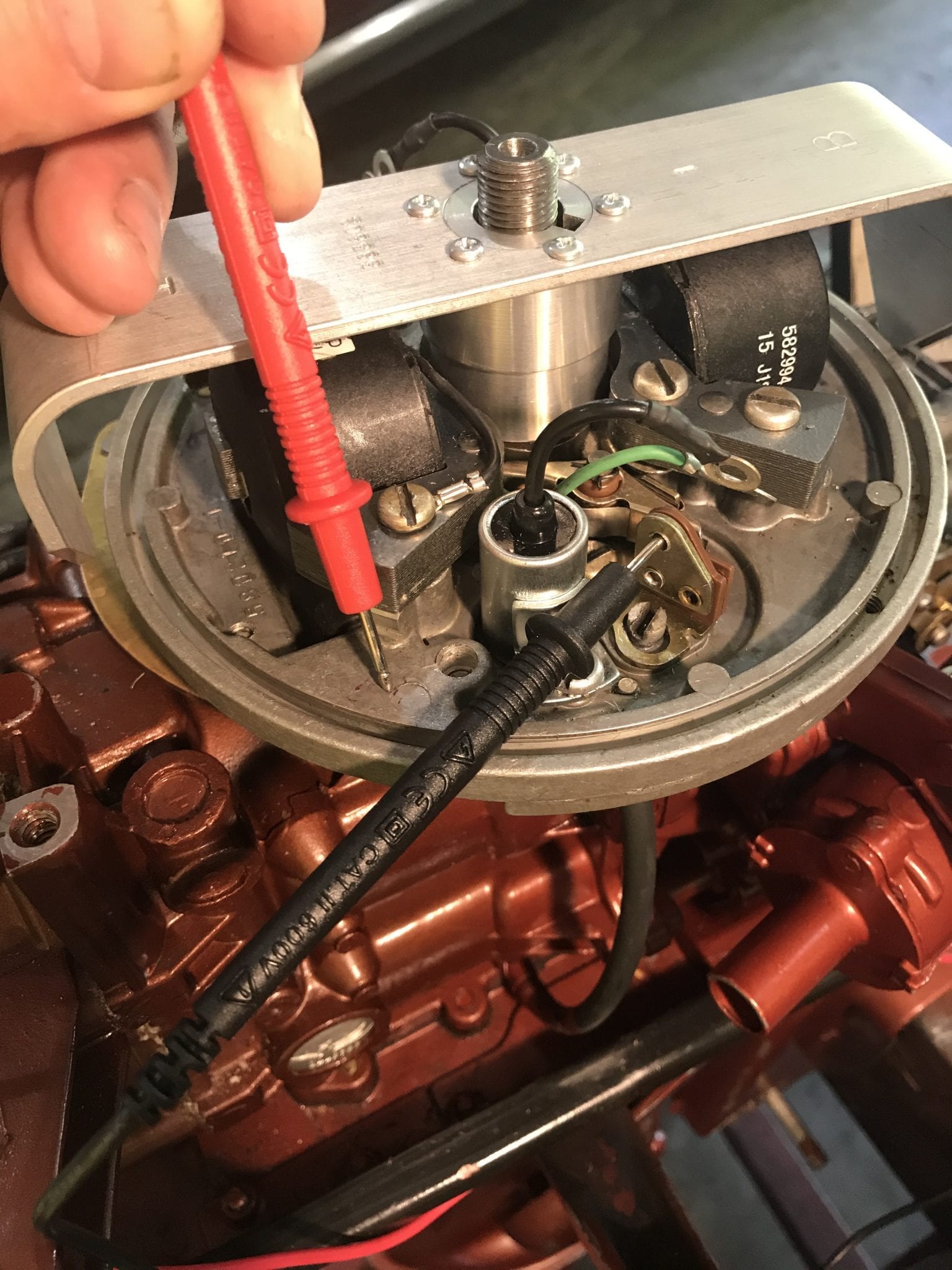

After you remove the plugs, can you post a photo with your meter connected? I’d like to see how you are hooking it up.

May 27, 2020 at 2:12 pm #204173I don’t have alligator clips. So been holding the red probe down on the mag plate and putting the black probe through the point with one hand. Using the screwdriver with the other hand. I will say I noticed if I just hold the red probe down on the plate and leave the black probe lie poking through the point but making contact, I can get the chirping to stop and the point looks slightly open. This is with the timing tool positioned correctly for the bottom. The top is still much easier to adjust. Also, I did remove the plug wires and twist the plugs out with a wrench.

-

This reply was modified 3 years, 11 months ago by

Mumbles.

Mumbles.

May 27, 2020 at 2:27 pm #204175Thanks BTW. This motor ran pretty nice after I put new coils in. But I feel like it should be giving a little more power at open throttle even if it is just a 5.5. Part of it is, I haven’t done much tinkering since last spring/summer when I worked on my 3s. I’m a bit rusty at this and still have a lot to learn. I did watch some great videos on YouTube by AOMCI members. I am learning how critical it is not to cut corners, use the right tools, right parts and do things right. I have the coil locator ring several timing tools and fuel connector repair tool from Richard.

May 27, 2020 at 6:27 pm #204185Do the points set screws have the tiny flat stainless washers? The points need to be able to pivot at that set screw for a full range of adjustment by turning the cam adjustment screw. Without the washers, I’m wondering if the set screws could be holding the points from rotating into proper adjustment?

May 27, 2020 at 7:02 pm #204187Yes. Tiny flat washers. Good idea though. Like I said, I was thinking perhaps I was applying too much pressure holding the black probe through the point. Maybe that’s preventing it from opening right. When I just lay it in there, it seems to work.

May 27, 2020 at 8:31 pm #204196I think the problem is poor contact between the probes and plate/points. Got a Home Depot or Lowes or Harbor Freight close by? You can get a little bundle of jumper wires with Alligator clips on each end for cheap.

May 27, 2020 at 10:33 pm #204207Thanks! I am going to pick some up from Amazon and they should be here by Saturday which is fine since I have to work tomorrow and go fishing for a few days after that!

May 28, 2020 at 7:49 am #204216That tool appears to be stamped correctly.

http://www.richardsoutboardtools.com

classicomctools@gmail.comMay 28, 2020 at 8:11 pm #204266The way the adjusting screw is in your photo, the points gap will tend to be narrow with the timing retarded. Turning the screw counter clockwise will widen the gap and advance the timing. Ignore what the gap looks like but read the meter instead. If the screw won’t open the points far enough, they can be pried open wider than necessary with a screwdriver and then the adjusting screw can be used to narrow the gap a little bit at a time while rotating the timing tool back and forth to check the timing.

May 29, 2020 at 8:05 am #204296Admittedly, I have not kept up with this thread….Nice looking 5.5 though…You mentioned low power output last year, you might want to check the propeller to ensure it is not the bigger pitch meant for the 7.5hp. Have you changed the gear lube? Perhaps the driveshaft shock spring has expanded causing the driveshaft to bind on the gearcase upper bushing/seal housing…

-

This reply was modified 3 years, 11 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.