Home › Forum › Ask A Member › Top Crank seal 10hp Johnson 1957

- This topic has 8 replies, 7 voices, and was last updated 3 years, 4 months ago by

seakaye12.

seakaye12.

-

AuthorPosts

-

September 10, 2021 at 2:47 pm #246450

I have to replace the the top crankshaft seal. this is one with the O-Ring and ceramic holder. I have a new O-ring and ceramic holder. To install it do I just push it down as it will goes and that’s it? just looks like that will seal it to me

Thanks Scott

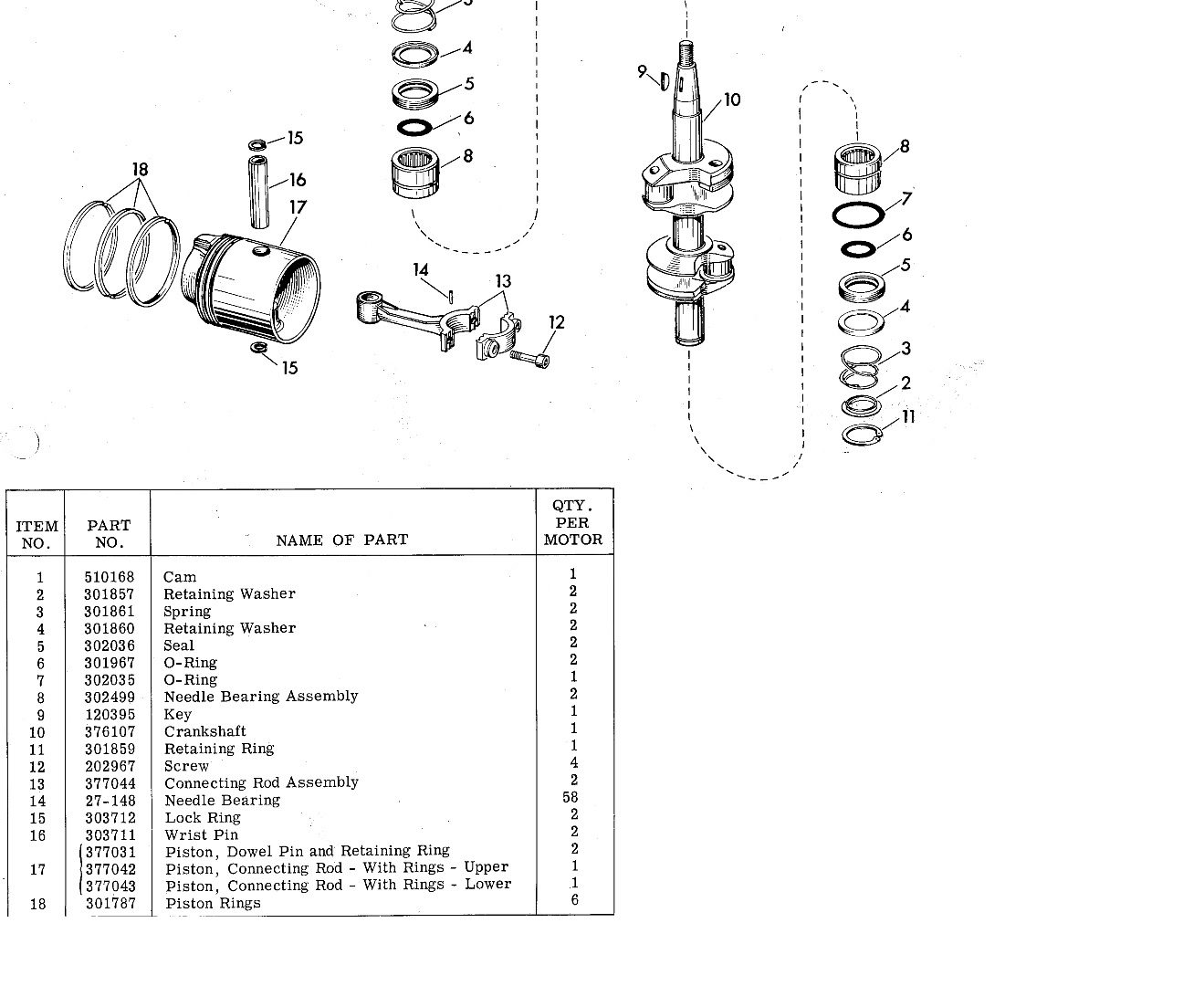

September 10, 2021 at 3:32 pm #246452There are several pieces to that upper seal assembly, more than just the “ceramic holder” and oring…. Sorry, I don’t have pictures, but will direct you to this parts diagram:

https://www.marineengine.com/parts/johnson-evinrude-parts.php?year=1958&hp=10&model=QD-19&manufacturer=Johnson§ion=Crankshaft+GroupSeptember 10, 2021 at 3:43 pm #246453Yes right. I have all those parts to put back in. Is that all do your thoughts

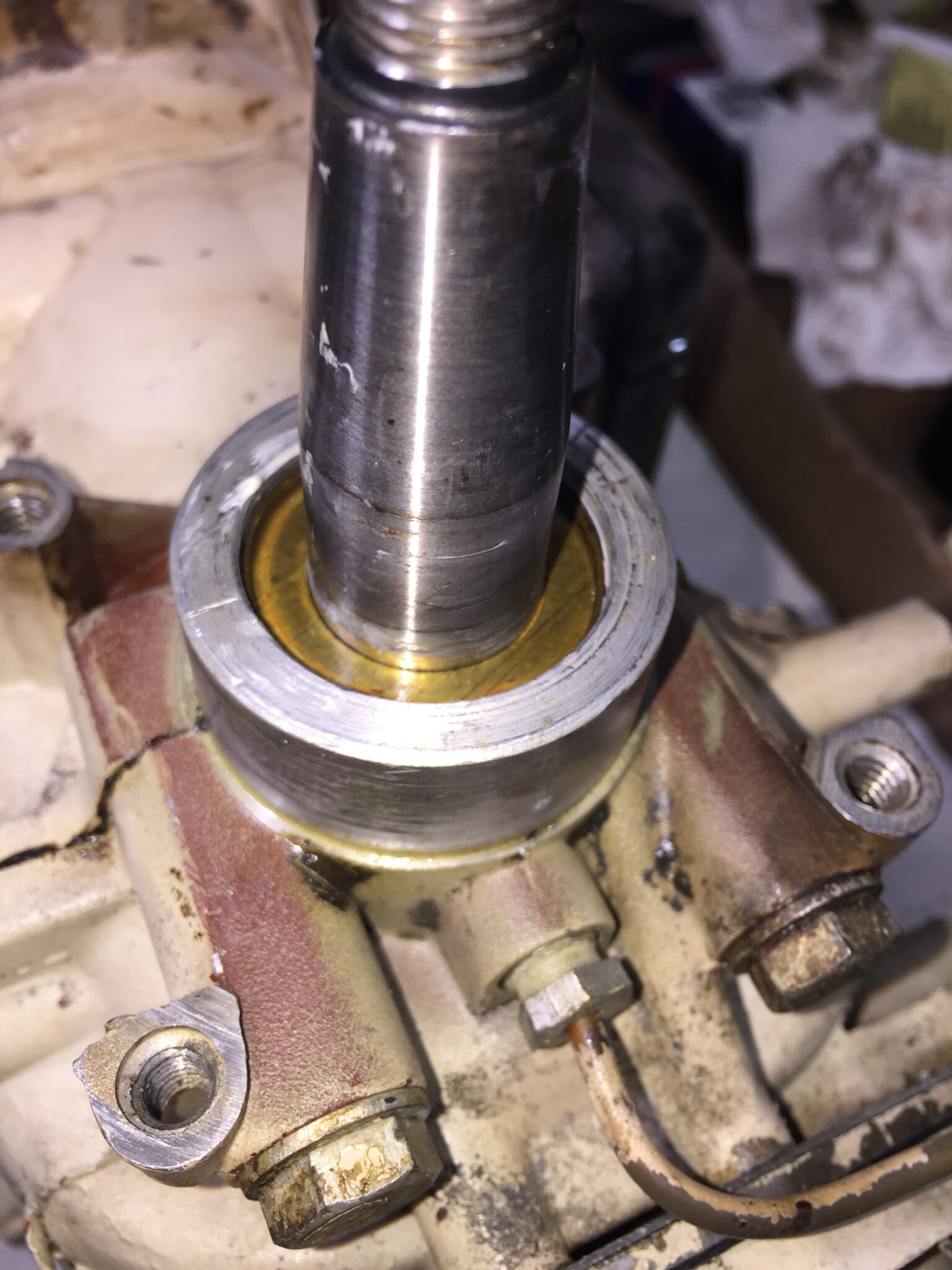

September 10, 2021 at 3:51 pm #246454Here’s a sequence of photos taken from my ’59 10hp showing the installation of the various pieces for the seal assembly. Note that when installing the carbon seal (what you called the ceramic holder) the side with the raised lip faces down toward the block and the side with the notches in it will be facing up.

Yes, just push the carbon seal down until it seats on top of the block. Be careful, as the carbon seal is somewhat fragile.

Bob

1937 Champion D2C Deluxe Lite Twin

1954 Johnson CD-11

1955 Johnson QD-16

1957 Evinrude Fastwin 18

1958 Johnson QD-19

1958 Johnson FD-12

1959 Johnson QD-20“Every 20 minute job is only a broken bolt away from a 3-day project.”

"Every time you remove a broken or seized bolt an angel gets his wings."September 10, 2021 at 4:04 pm #246461Thanks a lot pictures are worth a thousand words I can get done from hear THANKS

Scott

September 11, 2021 at 6:26 am #246478I have a 1957 QD19 johnson . what is the part number for the oring that fits over the lower crank bearing

0302035 is wrong. thanks for all helpSeptember 11, 2021 at 9:19 am #246480September 11, 2021 at 10:53 am #246489Just a heads up but on the ten horse motors, the seals spring likes to hold the points cam up above the points, especially if the cam is a loose fit on the crank. So when installing the flywheel, the crankshaft must be turned so the high point on the cam is centered between the rubbing blocks on the points. Failure to do this will result in a bent points arm or something else if the flywheel is forced down as the cam will not clear the points arm and will get hung up.

September 11, 2021 at 11:10 am #246490Just a heads up but on the ten horse motors, the seals spring likes to hold the points cam up above the points, especially if the cam is a loose fit on the crank. So when installing the flywheel, the crankshaft must be turned so the high point on the cam is centered between the rubbing blocks on the points. Failure to do this will result in a bent points arm or something else if the flywheel is forced down as the cam will not clear the points arm and will get hung up.

Yessir! Good Advice. Ten Horse owners should take notes and put those notes someplace where you can find them!

-

AuthorPosts

- You must be logged in to reply to this topic.