Home › Forum › Ask A Member › Trouble removing top pin on Johnson CD-11 driveshaft

- This topic has 5 replies, 3 voices, and was last updated 2 years, 7 months ago by

opposedtwin.

opposedtwin.

-

AuthorPosts

-

April 21, 2022 at 7:45 pm #258708

I don’t recall having so much trouble removing the top pin onthe driveshaft of a standard omc 5.5 hp. This one is model CD-11.

I find I’m having to drive the pin out but it’s fighting me the whole way. It doesn’t look like it’s a roll pin but it’s a mess.

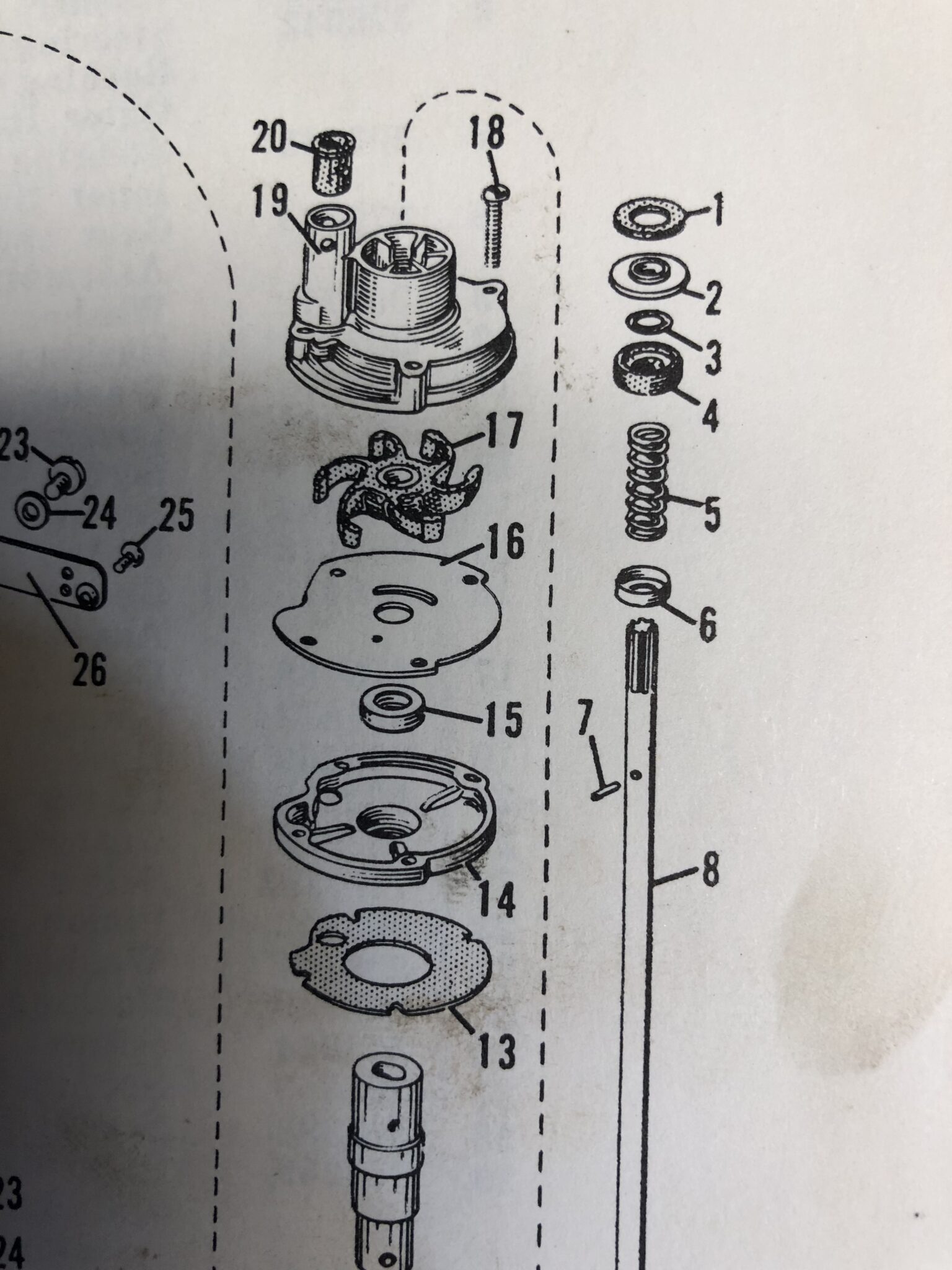

Part number 7 in the picture. Any help is appreciated.

ScottApril 21, 2022 at 7:58 pm #258711Why do you want to remove it? No reason to, unless it or the shaft is damaged. If you are thinking to remove the pump, just remove pump screws and pull the shaft out of the gearcase.

April 21, 2022 at 8:34 pm #258714I did that Frank but the impeller won’t slide off the bottom of the shaft. I know I’ve done it that way before but for some reason the brass inside of the impeller binds up on the spot where the shaft is machined to fit through the shock absorber.

EDIT: did a little fine filing on that spot and that allowed the impeller to slide off. Now to get that pin back the other direction.

-

This reply was modified 2 years, 7 months ago by

opposedtwin.

opposedtwin.

April 21, 2022 at 8:50 pm #258715Yeah, they do that. Just take a file to the burr and smooth it off.

1 user thanked author for this post.

April 23, 2022 at 10:45 am #258802You mention that the pin doesn’t appear to be the stock roll pin. Is it rusted up? It is possible that it is rusted and disintegrate over time leaving the seal assembly inoperative. Like Frank says, pull the upper driveshaft out of the unit with the impeller housing/impeller, then file the ridge on the bottom of the driveshaft. You may have better luck removing whatever is being used for the roll pin by clamping the upper driveshaft in a vice, using it to drive the roll pin at least flush on one side, then work it back and forth until it can be driven out with a little punch. On the other hand, maybe you want to leave it alone if it is not rusty, who knows what someone might have done/used instead of the OEM roll pin. Post pictures if you are concerned.

1 user thanked author for this post.

April 29, 2022 at 2:57 pm #259176fleetwin,

I’m not concerned at the moment. I guess time will tell. Got the impeller installed and just need to bucket test it if it ever warms up here in Wisconsin.

thanks for the help guys! Best advice ever is right here!

scott

-

This reply was modified 2 years, 7 months ago by

-

AuthorPosts

- You must be logged in to reply to this topic.