Home › Forum › Ask A Member › Two Line Gas Tank Seal and Gasket Replacement

- This topic has 14 replies, 7 voices, and was last updated 4 years ago by

Mumbles.

Mumbles.

-

AuthorPosts

-

March 19, 2021 at 9:40 am #234278

Thank you. Grainger has a branch about 30 minutes from my home.

The o-rings received from EBay are larger on both the thickness (9/64 vs 3/32) and outside diameter (7/16 vs 13/32) which would make them more difficult to install.

At the local Grainger outlet, here in Rhode Island, an order the previous day will arrive by 7:00 AM the following day. No shipping charge, just list price plus state sales tax. It’s a wonderful thing! A pack of 50 for $1.86.

-

This reply was modified 4 years, 1 month ago by

aquasonic.

March 30, 2021 at 9:54 pm #235315Having trouble with my refurbished gas tank leaking air. After trying to start my 1958 Evinrude 10 hp Sportwin, it would start rev up very high and then die and wouldn’t run until I primed it again. Not getting fuel.

I heard air hissing from the fuel tank which is new to me purchased with the motor, a 2 line gas tank that I refurbished with a new rubber diaphragm gasket, new cork sealing gasket, vinyl gaskets for the screws. I used my gear case tester modified with a 1/8 inch barb fitting to pump air into the tank through the air line fitting on the tank.

The tank is leaking from the relief valve, see attached photo with golf tee.

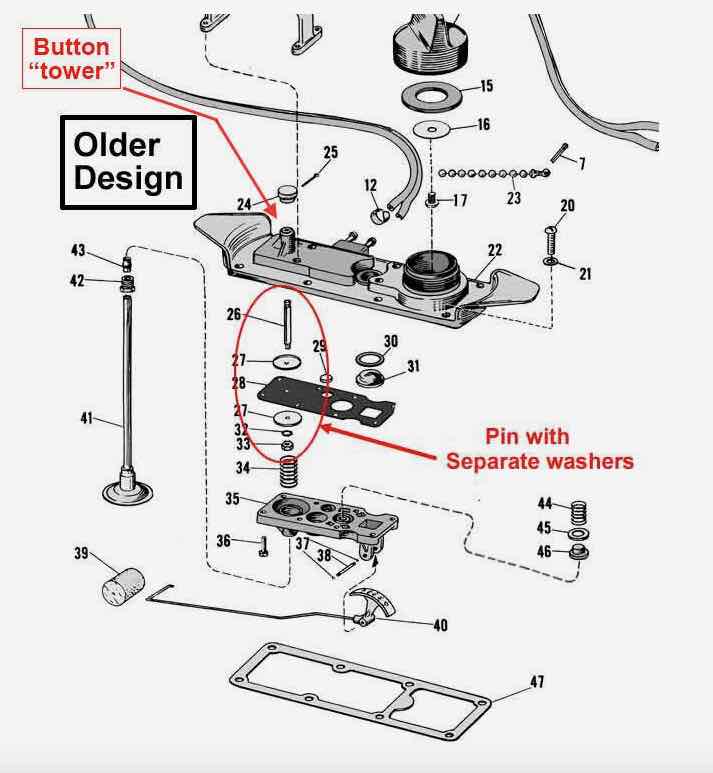

From the diagram above the relief valve part 46, OEM 0302136 is still soft and not brittle. The relief valve part 46 is seated against the housing and held in position by a spring. The relief valve has an indentation with the hole from the housing so I’m relatively confident it is in correctly. Upon careful examination I am missing part 29, OEM VALVE 0301802, I have misplaced it. I thought it was the center of the washer part 45. Mistake on my part.

What does the part 29 do. Appreciate your help.

Thank you.

March 31, 2021 at 5:17 pm #235354The part 29 from your diagram is a tiny aluminum disk that serves as a backflow preventer for the outgoing fuel. The disk sits at rest with gravity, sealing the fuel supply from the lower housing until the outgoing fuel supply lifts it off of its seat and allows fuel to exit from the barb labeled “fuel”. If fuel tries to return to the tank, the disk is pushed back downward and seals the supply preventing backflow,

This backflow preventer system has no connection to the pressure relief valve, so it’s confusing as to why air is getting past the rubber relief seal (PN 46 on your diagram). The pressure relief valve is a simple chamber with an outlet. An overly pressurized tank pushes PN 46 upward, releasing vapor pressure by overcoming the pressure generated by the opposing spring labeled PN 44.

I can only speculate, that without the tiny disk, pressure is somehow leaking into the backside of the pressure relief valve. Once the pressure is behind the valve, it will go directly out of the opening in the upper housing, and into the atmosphere. This would have nothing to do with correct assembly of the pressure relief assembly.

1 user thanked author for this post.

March 31, 2021 at 7:54 pm #235370Thank you Aquasonic

Based on your reply and other posts I decided to remediate the pressure relief valve with a temporary fix, the indentations on the valve convinced me to try, photo of the relief valve attached below.

I removed the valve and coated the top of it with Star Brite Liquid Electric Tape which I have used to seal electrical components from the elements. This product dries to a semi hard solid like hard rubber. The coating filled in the indentations created by the valve being in the same spot for so many years.

In addition, to replace part 29 I ground down a brass screw head to the diameter to fit into the space for the part. The head of the screw is the same thickness as the washer part 45.

Pressure tested the gas tank and it holds pressure, the relief valve was bad. I have a new one on order and will replace when it arrives.

Started my engine for the first time tonight.

April 2, 2021 at 11:18 am #235430If the motor starts and dies shortly after starting, the tank may be low on fuel and hasn’t had enough time to get pressurized. Additional priming when the motor starts may be necessary until enough pressure builds up in the tank to force the fuel to the carb.

1 user thanked author for this post.

-

This reply was modified 4 years, 1 month ago by

-

AuthorPosts

- You must be logged in to reply to this topic.